I will describe what I've done and what I plan to do, and hope someone can tell me if I am getting off the track at any point.

I started a SMASH on Sunday with Avangard Pilsner Malt, YCH Cryo-Mosaic hops, and Imperial Dry Hop yeast. OG was 1.058. Targets are 6.1% ABV and 61 IBUs, so naturally I named it Highway 61 Revisited. I accidentally pitched at about 78F (package says 67-72), but my fermentation chamber got the temp down to 68 fairly quickly.

I reset to 70F on Tuesday and dry-hopped on Wednesday when the hydrometer read just a hair under 1.030. I will not see the brew again until Saturday afternoon.

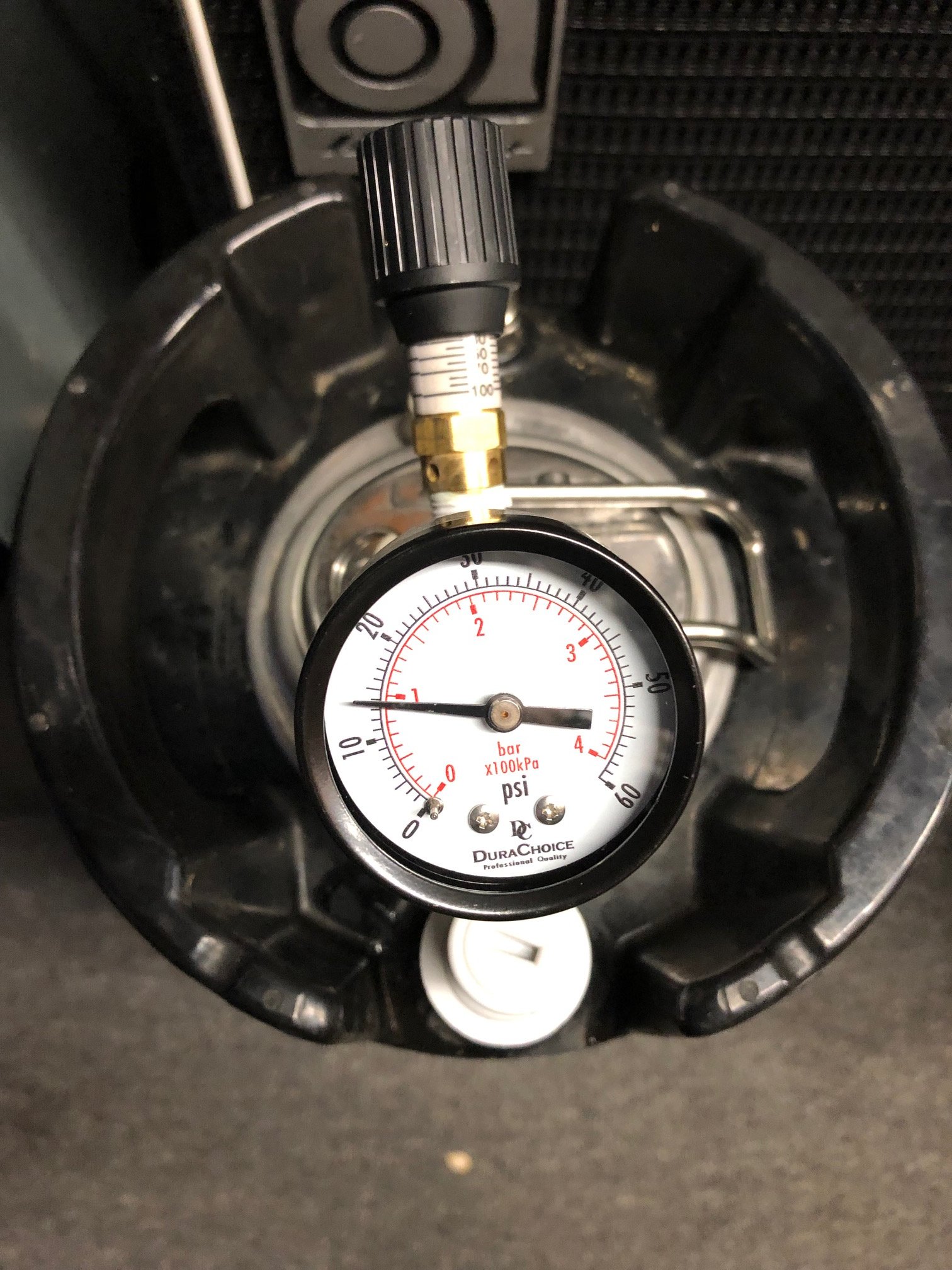

I bought this Gov Reg Dispensing Regulator for $25 at the AHA shindig in Portland:

http://www.itwprt.com/us/gov-regulator.php

It is pre-set at 12psi and I did not spend the bucks on the ability to adjust it. They represent that it will hold this setting indefinitely or until it is adjusted.

Assuming my beer is not already done fermenting when I get home tomorrow, I want to transfer from my Catalyst conical to a keg when I have 6-10 points of fermentation left to go. I will do some sort of O2 purge to the keg before transferring, but figuring out the whole O2 free transfer thing will have to wait for another brew. I plan to leave as little headroom as possible in the keg. I also plan to throw a Clear Beer gadget into the keg so that my first draw will be trub-free.

The folks from ITW said to take a quick-connect from a keg, attach about a foot of thick-walled tubing with a clamp, and then clamp the Gov Reg device to the other end of the tube.

I will attach this assembly (note, no gauge of any sort here) to the out port of the keg and put it back in the FC to finish fermenting at 70F. Assuming I do all of this on Saturday or Sunday, I will wait until Wednesday to do a gravity check. I guess I will need to de-gas the beer to get an accurate reading.

Assuming the beer is done, I will then cold crash at about 35F for about three days.

How does all of this sound?

Now that I have typed all of this out, I see I have another question or two. If this winds up under-carbed, I know I can always top it off with tank CO2. So, let's assume I get the carbing right. Now what? Do I use this natural pressure to serve, like a "real ale" with gravity service, or do I attach a CO2 tank to serve? Assuming the latter, at what pressure do I serve?

I started a SMASH on Sunday with Avangard Pilsner Malt, YCH Cryo-Mosaic hops, and Imperial Dry Hop yeast. OG was 1.058. Targets are 6.1% ABV and 61 IBUs, so naturally I named it Highway 61 Revisited. I accidentally pitched at about 78F (package says 67-72), but my fermentation chamber got the temp down to 68 fairly quickly.

I reset to 70F on Tuesday and dry-hopped on Wednesday when the hydrometer read just a hair under 1.030. I will not see the brew again until Saturday afternoon.

I bought this Gov Reg Dispensing Regulator for $25 at the AHA shindig in Portland:

http://www.itwprt.com/us/gov-regulator.php

It is pre-set at 12psi and I did not spend the bucks on the ability to adjust it. They represent that it will hold this setting indefinitely or until it is adjusted.

Assuming my beer is not already done fermenting when I get home tomorrow, I want to transfer from my Catalyst conical to a keg when I have 6-10 points of fermentation left to go. I will do some sort of O2 purge to the keg before transferring, but figuring out the whole O2 free transfer thing will have to wait for another brew. I plan to leave as little headroom as possible in the keg. I also plan to throw a Clear Beer gadget into the keg so that my first draw will be trub-free.

The folks from ITW said to take a quick-connect from a keg, attach about a foot of thick-walled tubing with a clamp, and then clamp the Gov Reg device to the other end of the tube.

I will attach this assembly (note, no gauge of any sort here) to the out port of the keg and put it back in the FC to finish fermenting at 70F. Assuming I do all of this on Saturday or Sunday, I will wait until Wednesday to do a gravity check. I guess I will need to de-gas the beer to get an accurate reading.

Assuming the beer is done, I will then cold crash at about 35F for about three days.

How does all of this sound?

Now that I have typed all of this out, I see I have another question or two. If this winds up under-carbed, I know I can always top it off with tank CO2. So, let's assume I get the carbing right. Now what? Do I use this natural pressure to serve, like a "real ale" with gravity service, or do I attach a CO2 tank to serve? Assuming the latter, at what pressure do I serve?