You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

someone has built a picking-hops machine?

- Thread starter DoooC

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

broadbill

Well-Known Member

yes, they exist.

broadbill

Well-Known Member

The machines I was referring to are commercial, farm-duty machinery. Ones used to harvest hops acres at a time. I don't know of a smaller version.

HopStalker

Member

Here are some more documents with detailed plans. With labor, they estimate it cost $50K.

http://www.uvm.edu/extension/cropsoil/wp-content/uploads/Callahan_Mobile_Hop_Picker_3_19_2012.pdf

http://www.uvm.edu/extension/cropso...UVM-Hop-Harvester-Project-Report-Drawings.pdf

http://www.uvm.edu/extension/cropsoil/wp-content/uploads/Callahan_Mobile_Hop_Picker_3_19_2012.pdf

http://www.uvm.edu/extension/cropso...UVM-Hop-Harvester-Project-Report-Drawings.pdf

@B-Hoppy and @HopStalker

Thanks for all the details - I'm going to stash those away as I think about what to build for next fall.

With a several hundred plants, hand picking is getting really tedious, but these machines would be overkill. Instead, I am thinking about constructing separate devices for 1) plucking and 2) sorting. Hops wold be plucked on-site and then transported to a small dribble belt setup at home.

For the plucker, I'm simply thinking about a set of rotating stripping fingers powered by an electric mortar. Bines would be pulled through by hand.

Anyone have a source for a few dozen striping fingers? Otherwise, I might just set up a jig and make them myself.

Thanks for all the details - I'm going to stash those away as I think about what to build for next fall.

With a several hundred plants, hand picking is getting really tedious, but these machines would be overkill. Instead, I am thinking about constructing separate devices for 1) plucking and 2) sorting. Hops wold be plucked on-site and then transported to a small dribble belt setup at home.

For the plucker, I'm simply thinking about a set of rotating stripping fingers powered by an electric mortar. Bines would be pulled through by hand.

Anyone have a source for a few dozen striping fingers? Otherwise, I might just set up a jig and make them myself.

Baja_Brewer

Well-Known Member

Subbed, cool stuff.

@B-Hoppy and @HopStalker

For the plucker, I'm simply thinking about a set of rotating stripping fingers powered by an electric mortar. Bines would be pulled through by hand.

Anyone have a source for a few dozen striping fingers? Otherwise, I might just set up a jig and make them myself.

I remember seeing someone once state that they mounted a few of those fingers on a drill. It may have been @GVHDan, you could always pm him as they build pickers.

EcuPirate07

Beer is a food group

I think undocumented workers would be cheaper

This may be too small to read but it has all the commercial harvesters (save 1) that are out there. You can look through the list but most of these start at $20k.

Our bine 3060 was only $14k but it won't be made, at least for this year. too much of a distraction.

If you are looking for ideas, look through these. The simplest is a bar with a few picking fingers (yep, drill powered) to strip them off the bine. Then take the cones and leaves and pour them on a tarp in front of a box fan. After a couple of times, you should be rid of most of the leaves.

If you need picking fingers, send me a PM. We may have a few laying around or I can give you a contact

View attachment New Picture (13).bmp

Our bine 3060 was only $14k but it won't be made, at least for this year. too much of a distraction.

If you are looking for ideas, look through these. The simplest is a bar with a few picking fingers (yep, drill powered) to strip them off the bine. Then take the cones and leaves and pour them on a tarp in front of a box fan. After a couple of times, you should be rid of most of the leaves.

If you need picking fingers, send me a PM. We may have a few laying around or I can give you a contact

View attachment New Picture (13).bmp

The simplest is a bar with a few picking fingers (yep, drill powered) to strip them off the bine.

Wow, I would love to see a pic of this! Was it mounted on a table, or was it hand held?

Also... for whatever reason - that pic is too small to make out any text.

It was about 3 feet long, mounted on a couple of pillow block bearings on some sawhorses...if I can remember correctly. Sorry, I don't think we ever snapped a picture but its basically the same as the picking drum inside our Bine 3060. The difference is the gaurding, which you will have to build to keep hops from flying everywhere.

We ran the first couple with a drill but eventually it had a slip clutch so it wouldn't take you fingers off.

We ran the first couple with a drill but eventually it had a slip clutch so it wouldn't take you fingers off.

HopStalker

Member

The simplest is a bar with a few picking fingers (yep, drill powered) to strip them off the bine.

That sounds like a cool "hack", but I'm guessing that you probably need to mount it in some sort of tunnel or hopper so it doesn't spray cones and lupulin all over. Also, if you're using a cordless, I could see battery issues too. I have an old Honda lawnmower engine around that I'm thinking of using if the exhaust isn't too bad (if it is, could make a long exhaust pipe

When I was searching the web for picking fingers (that's where I originally came across the UVM harvester), I didn't find much. My most interesting findings were patent filings.

I could probably make something from what I found searching Alibaba, Grainger, Home Depot, etc. for double torsion springs, but they aren't ideal.

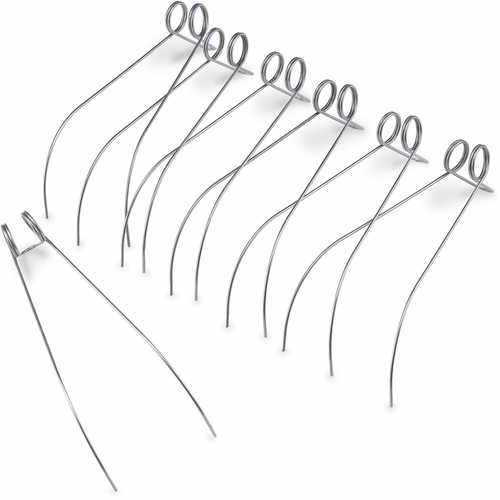

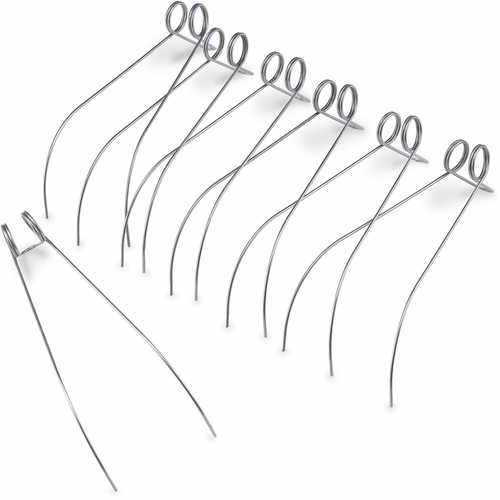

I don't have a lathe, but I'm thinking of doing something more like this:

https://youtu.be/vn9dDYzdorg

Also, I think I've watched every Bine 3060 video and a lot of other harvester videos on youtube. Here's a decent video that will give you an idea of what you're getting into. If I make something like this, I think I would reverse the shaft with the pickers, reverse the rotation direction, and run the bines through the top of the hopper so that gravity pushes the bines into the picking fingers instead of away from the picking fingers:

https://youtu.be/npVfinz6o1E

At one point, we had a few hundred of those laying around the workshop. Not sure what's left. Otherwise, that table I just posted has Danhauer's contact info. He sells picking fingers but I don't know how small of a quantity.

Otherwise, set yourself up a jig and start bending. I know a lot of people that have.

Otherwise, set yourself up a jig and start bending. I know a lot of people that have.

@B-Hoppy and @HopStalker

Anyone have a source for a few dozen striping fingers? Otherwise, I might just set up a jig and make them myself.

That sounds like a cool "hack", but I'm guessing that you probably need to mount it in some sort of tunnel or hopper so it doesn't spray cones and lupulin all over. Also, if you're using a cordless, I could see battery issues too. I have an old Honda lawnmower engine around that I'm thinking of using if the exhaust isn't too bad (if it is, could make a long exhaust pipe).

Woooo there cowboy. You looking to loose some fingers? Like I said, the cordless drill was on the prototype but the battery ran out too quickly. When we put together the first real Bine 3060, we used a partial hp DC motor so we could easily vary the speed and the slip clutch so if you grabbed it, the dang thing stopped.

If slap a lawn mower motor on it, even if you can fine tune it to the correct speed, it will have so much torque it will rip something off of you.

When I was searching the web for picking fingers (that's where I originally came across the UVM harvester), I didn't find much. My most interesting findings were patent filings.

I could probably make something from what I found searching Alibaba, Grainger, Home Depot, etc. for double torsion springs, but they aren't ideal.

I don't have a lathe, but I'm thinking of doing something more like this:

https://youtu.be/vn9dDYzdorg

You can make them very easily but they are cheaper to buy.

Also, I think I've watched every Bine 3060 video and a lot of other harvester videos on youtube. Here's a decent video that will give you an idea of what you're getting into. If I make something like this, I think I would reverse the shaft with the pickers, reverse the rotation direction, and run the bines through the top of the hopper so that gravity pushes the bines into the picking fingers instead of away from the picking fingers:

https://youtu.be/npVfinz6o1E

First, those guys didn't fully read the instructions. Or more likely, that was their first attempt at using the machine and learned more over time. The fingers were moving WAY too fast. Different varieties require different speeds. They also would have done better cutting the bine into 4 foot lengths to feed in.

I hear what you are saying but if you reveresed everything and let the bine drape over the top, you end up getting a lot of side arms and cluster breaking away that you need to re-pick. By placing it underneath as we did, expose the cones and foliage to the picking fingers a little at a time so you don't get the clusters.

HopStalker

Member

Woooo there cowboy. You looking to loose some fingers?

If slap a lawn mower motor on it, even if you can fine tune it to the correct speed, it will have so much torque it will rip something off of you.

I was a little worried about safety, but after seeing the guy in the video sticking his hands in there I figure it must be no big deal

I haven't looked closely at the lawn mower - I'm just brainstorming. I'm thinking of using the part of the drivetrain that powers the wheels. It already has a speed control and an easy start/ stop lever. Not sure what I would do about a clutch or automatic shut off...

Last edited:

I understand the value of Hillbilly engineering but start with something else. Maybe grab a corded variable speed drill from a garage sale and strip that apart.

People are able to stick their fingers in it (not that we recommend it) because of the low power and slip clutch. It honestly doesn't take much to beat the cones off. There are a lot of ways to do that. Separating leaf and stem from cones is the hard part.

People are able to stick their fingers in it (not that we recommend it) because of the low power and slip clutch. It honestly doesn't take much to beat the cones off. There are a lot of ways to do that. Separating leaf and stem from cones is the hard part.

So... harvest time is upon us and I never got around to building a picking machine. Time to scale back a bit.

Rather than a motorized machine, I'd be happy with a hop rake at this point. Originally, I was going to try welding together the tines on a regular leaf rake to form loops. Then I came across the "Groundskeeper II" which has parallel tines made from torsion springs! They should form perfect fingers when tacked together. I just ordered the rake on amazon, but it also looks like you can pick up just the tines from places like forestry-suppliers.com

I'll report back if any of this works out.

Rather than a motorized machine, I'd be happy with a hop rake at this point. Originally, I was going to try welding together the tines on a regular leaf rake to form loops. Then I came across the "Groundskeeper II" which has parallel tines made from torsion springs! They should form perfect fingers when tacked together. I just ordered the rake on amazon, but it also looks like you can pick up just the tines from places like forestry-suppliers.com

I'll report back if any of this works out.

whiskertooth

New Member

- Joined

- Jul 15, 2017

- Messages

- 4

- Reaction score

- 2

Hi Dan, are there any plans for the bine 3060 available?

Plans...at this point we don't have plans we could really provide to anyone else that could be comprehended and since we don't build it any more, there's no point in cleaning them up.

I can tell you there are at least 2 used units for sale out there. I saw one of the newest models on Facebook for $9k.

I can tell you there are at least 2 used units for sale out there. I saw one of the newest models on Facebook for $9k.

whiskertooth

New Member

- Joined

- Jul 15, 2017

- Messages

- 4

- Reaction score

- 2

Hi Dan, thank you for replying! I will keep a lookout for any second hand machines. I'm in England and on a major budget, however have access to a metal working workshop and lot of old bits of agricultural machinery. So was hoping to recreate the picking unit on your machine!

The one for sale on facebook is in the "Hop Growers Forum (Nationwide)" group. I don't know how to share the link directly to the post but it was put up on July 11th by Christoph Aaron. He's asking $9k.

If nothing else, he has the pictures up as do many others. I'm also looking to see if we still have the assembly instructions. From that, you may be able to recreate it. I'll see what I can find but I can tell you that if you were to re-build it exactly, it would cost more than the $9k he's asking. Of course, I have no idea what it would cost to ship to England.

If nothing else, he has the pictures up as do many others. I'm also looking to see if we still have the assembly instructions. From that, you may be able to recreate it. I'll see what I can find but I can tell you that if you were to re-build it exactly, it would cost more than the $9k he's asking. Of course, I have no idea what it would cost to ship to England.

whiskertooth

New Member

- Joined

- Jul 15, 2017

- Messages

- 4

- Reaction score

- 2

Thankyou Dan, you are a good man! I've been working in a copy of the stripping unit you created. Will post up some pics when I get a chance. It's been quite fun/challenging trying to scale the dimensions of components from the pictures available online! What sort of rpm is the picking drum typically spinning at? I've got a motor from a press drill with two cone pulleys allowing some control of speeds. Thankyou again for any help!

I'll have to go back and find my notes but its not that fast. Actually, variable speed is the best because they all pick different.

whiskertooth

New Member

- Joined

- Jul 15, 2017

- Messages

- 4

- Reaction score

- 2

Where I have got to so far, it seems pretty effective at stripping wheat and barley, will start work on the guards and work on slowing the motor down. I have a variable speed controller, but the wiring instructions are in Chinese and a little hard to figure out!

Where I have got to so far, it seems pretty effective at stripping wheat and barley, will start work on the guards and work on slowing the motor down. I have a variable speed controller, but the wiring instructions are in Chinese and a little hard to figure out!

Similar threads

- Replies

- 3

- Views

- 269