skraeling

Scientist Extraordinaire

- Joined

- Sep 26, 2013

- Messages

- 721

- Reaction score

- 285

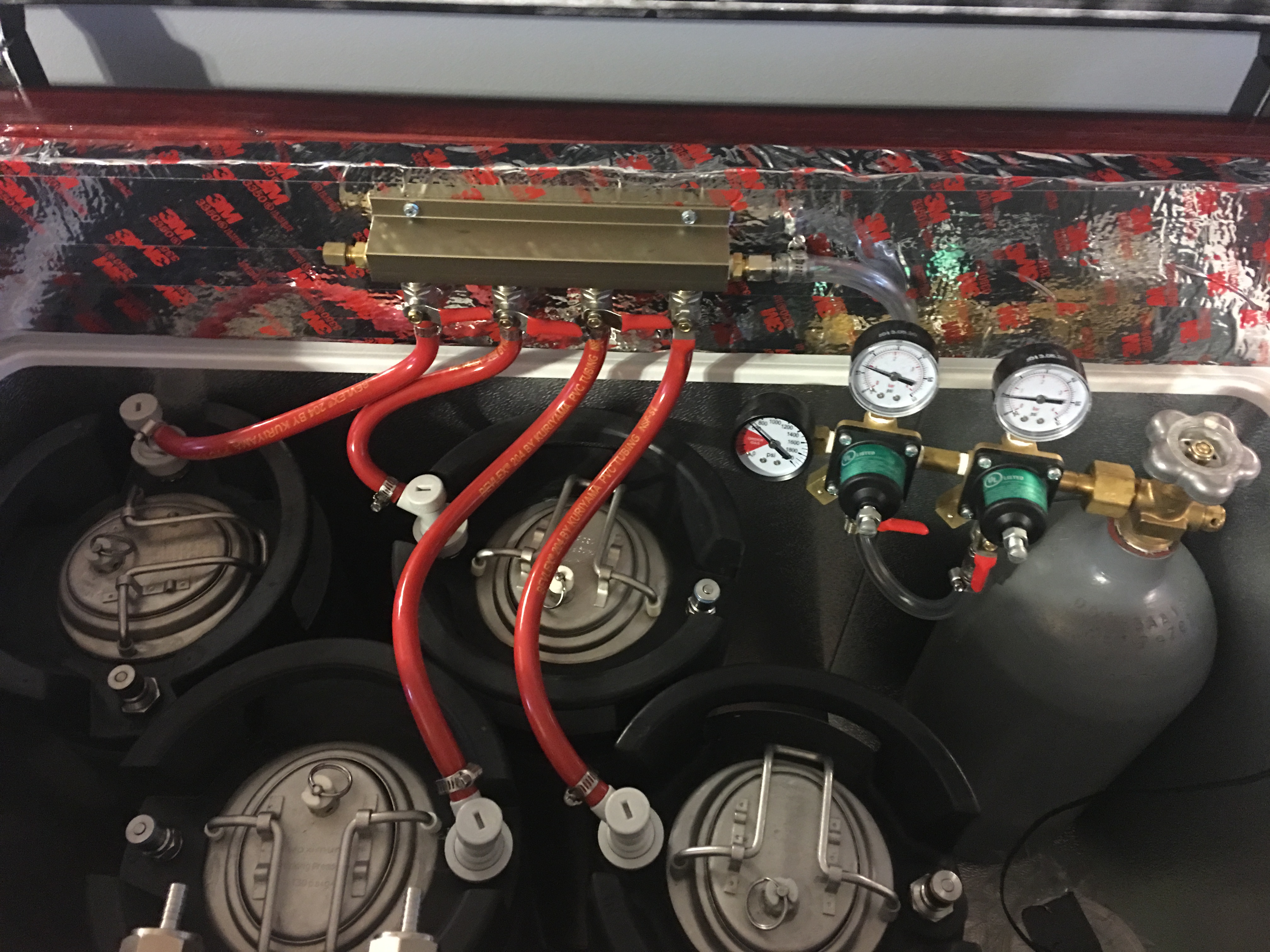

So parts have finally arrived. Still waiting on two kegs that I just ordered.

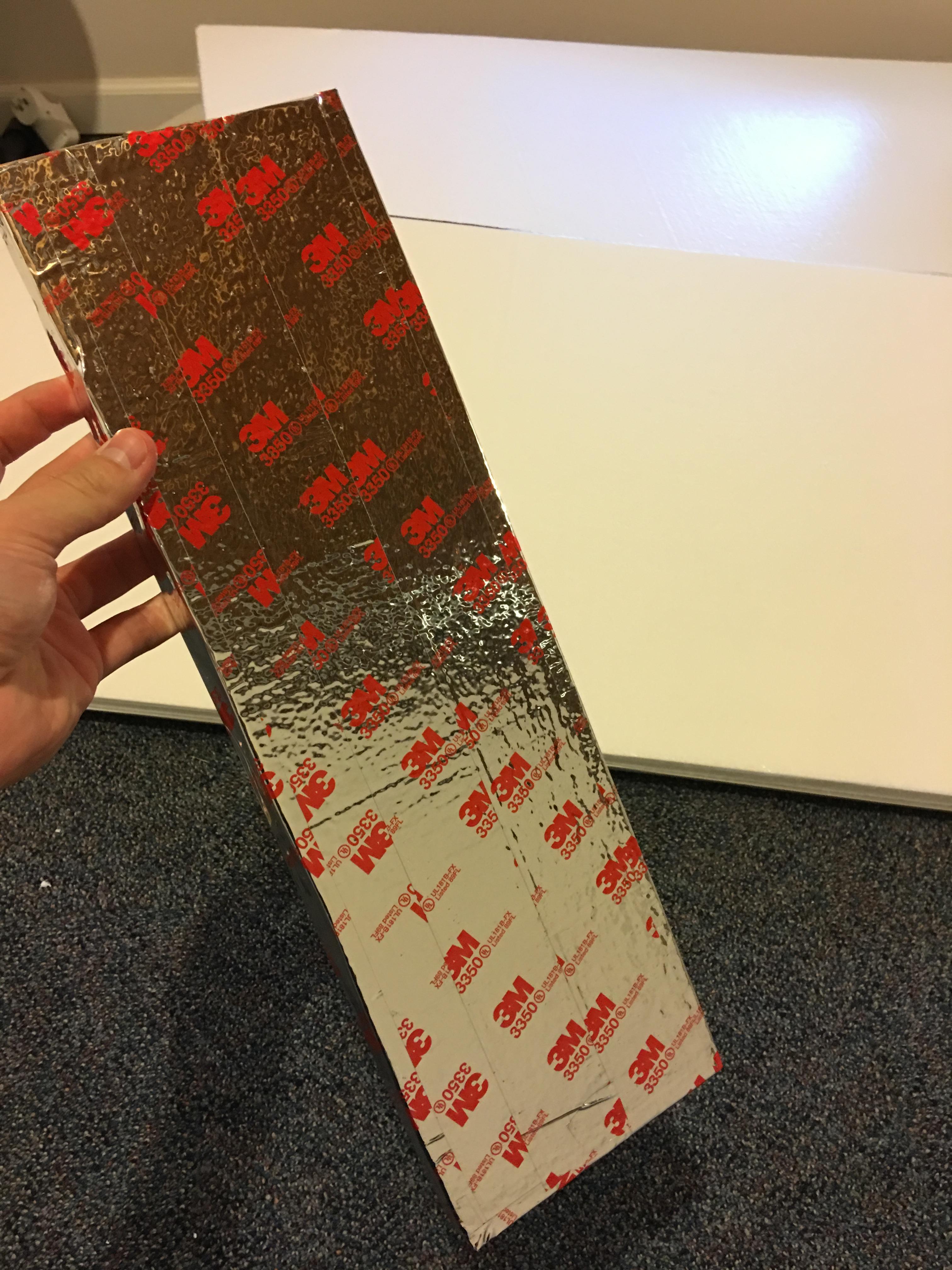

Parts so far

I still need to order a gas manifold two more faucets plus associated lines and fittings.

Testing out stain on cedar. Yeah that'll look real nice. Still need to pick up the poly for a shiny top layer though.

View attachment ImageUploadedByHome Brew1476565311.254214.jpg

View attachment ImageUploadedByHome Brew1476565357.318322.jpg

Parts so far

I still need to order a gas manifold two more faucets plus associated lines and fittings.

Testing out stain on cedar. Yeah that'll look real nice. Still need to pick up the poly for a shiny top layer though.

View attachment ImageUploadedByHome Brew1476565311.254214.jpg

View attachment ImageUploadedByHome Brew1476565357.318322.jpg