What is wrong with using Cat5e/Cat6/Cat3 (telephone or network) connectors for the temp probes. They are cheap and readily available in HomeDepot & Lowes etc. They have been working flawlessly for me the last 10 years.

I have 5/16 inch homemade brass tube thermowells that my probes just slide into. The Pt100 probe I have, as well as my home made transistor temp sensors fit nicely.

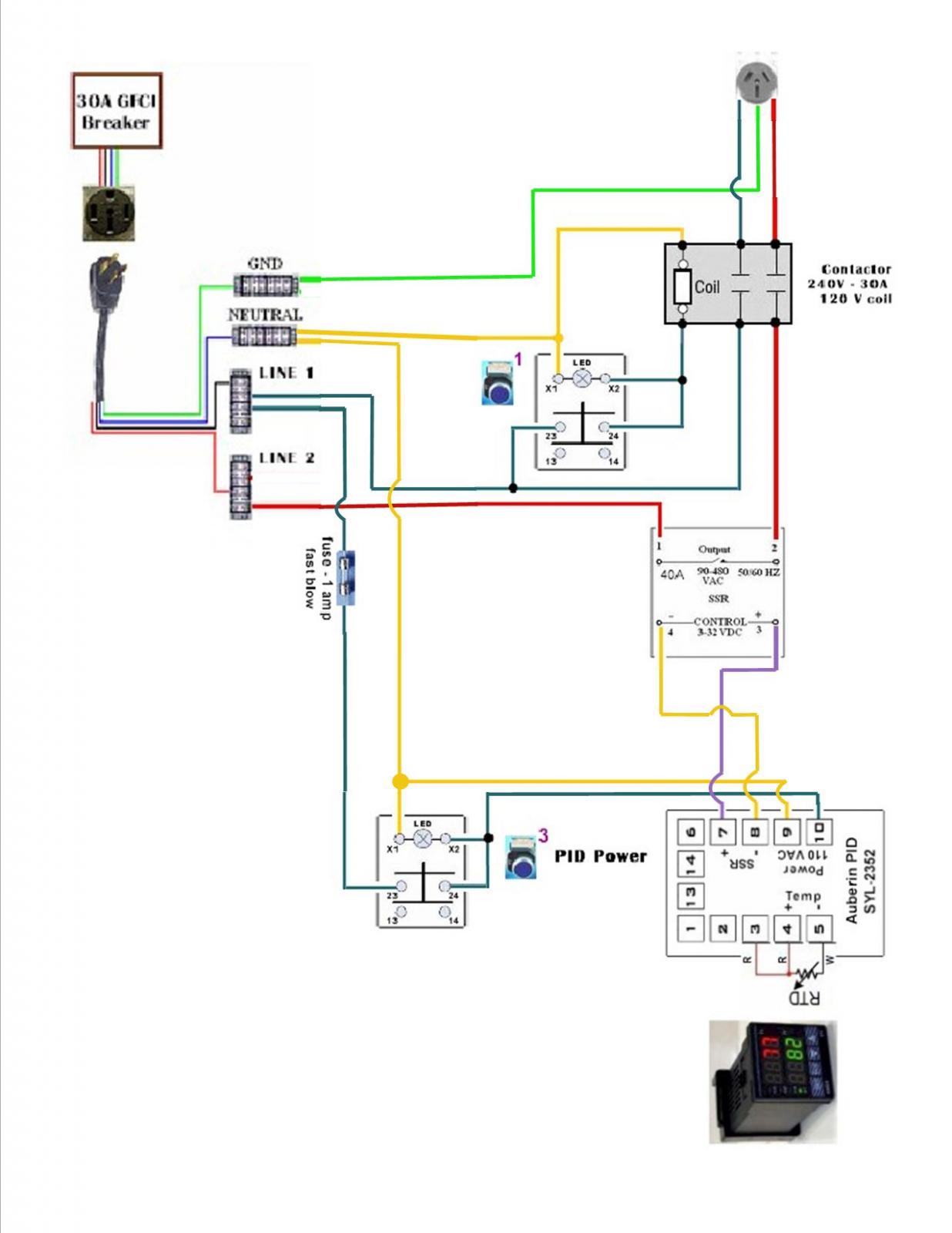

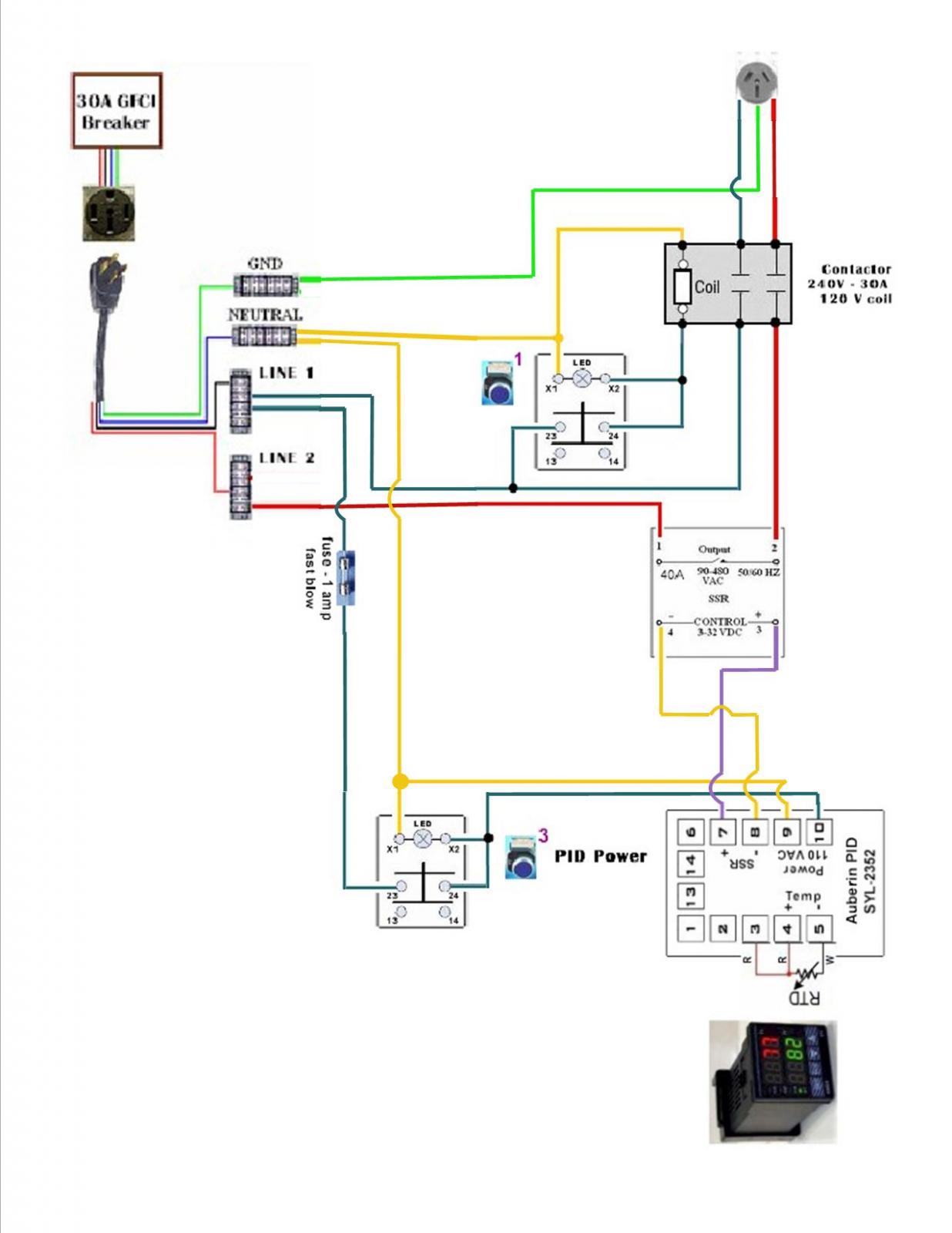

Are you building a Commercial setup with liability issues? I just don't get the OSHA type wiring diagrams. I DO understand that a business cannot publish potentially risky schematics, but geez; a PID attached to a SSR attached to an element via a double pole single throw switch is not that scary.

Why use a PID for the HLT? Why not a simple $5.00 t-stat? My first one was a hot water heater t-stat glued to the tank, worked fine. I do have a 240V HLT, but I'm wondering why lately; I have at least an hour to heat 12 gallons up to 170F.

In 20 years of inventing my own RIMS system I have never had a need for a E-stop or experienced a stuck SSR. I did get a few zaps before I understood grounding a metal pot with an element in it was a good idea.

I started with a manual switch and an element in a plastic bucket and lots of nerve and only one major scalding event (don't boil in a PVC bucket!).

I just joined HBT, so I have not had time to publish any of my pics etc.

This is not intended to be a rant, if that's what it seems. I just don't have the time nor the money to worry about suing myself if I get electrocuted.