BrewBeemer

Well-Known Member

Liquid nitrogen would be faster yet I am sure.

I'm a 20# Co2 fire extinguisher to 6-pack chilling person myself.

Mythbusters anyone?

Liquid nitrogen would be faster yet I am sure.

I love the humorous comments about the ice bottles in the bucket, it looks realistic when the math is done.

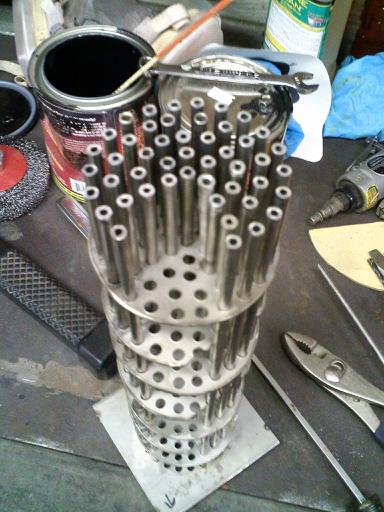

Here is mine. Taking my time with it. It is a tube/shell style heat exchanger made from 304 stainless. The wort will flow through the tubes and the chilling water will flow through the shell. The shell is not installed in photos below, and I still have a few tubes to install.

Original design was 57x12" long tubes of 3/16" OD in a 3" shell. The tubes are 11.875. I have 7 baffles to cause turbulence. On each end there will be a sanitary fitting and cap (with wort passage) fit with gasket and triclamp so I can remove the core for cleaning.

The design was simulated to cool 212F wort to 92 with 45F water (from my prechiller) first pass, and since I recirculate through the brew kettle to whirlpool, I should be able to get the wort down fast with this device.. <crosses fingers>

I f@@ked up, the 12 liters of ice is BS , I plugged the information to the heat exchange calcs at work and best it could ever get the wort cooled down to was 86 degrees, it was possible in theory if 17 liters was used but, the 10 gallon bucket would be full to almost overflowing.

More progress:

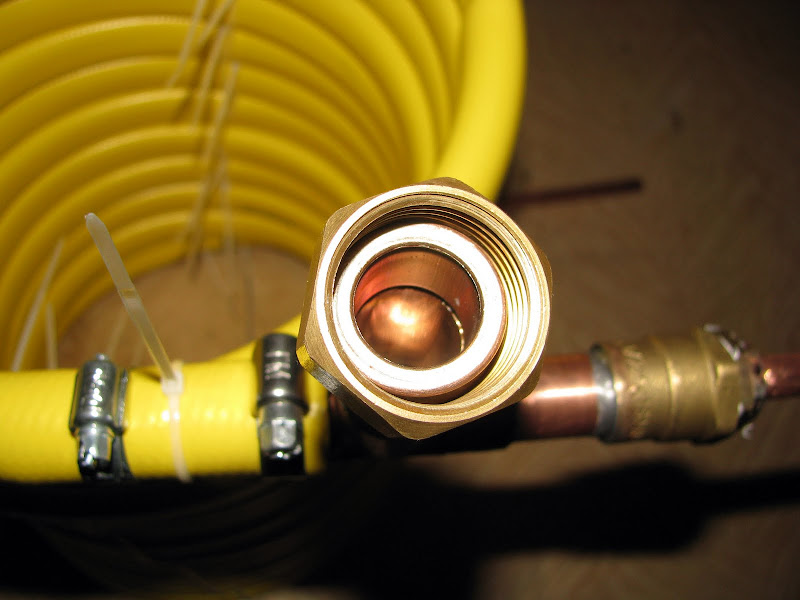

Here is how the end tanks will fit on. Half of the sanitary fitting will be welded to the end plate, and the cap will have a fitting welded in to connect a 1/2 hard pipe to my manifold.

I think DavidR probably has the coolest looking cooler I've seen on this forum... That thing is ridiculous. How turbulent can you keep the coolant?

Props to you sir. This is the first non-IC I've seen here that can be inspected visually.

I'm a 20# Co2 fire extinguisher to 6-pack chilling person myself.

Mythbusters anyone?

At some point in that conversation I found out they didn't need any help on the show from a mechanical engineering student.

Adam's my fun loving hero, Jamie I find rather an odd duck I met both several times at the old Alameda Navel Air Station the island for many tests.

With Nam in the early 70's myself a A&P mechanic at a Allison 501-D13 engine shop were contracted out pulling maintenance on C-130 engines. On these monthly reserve weekends the Navy had emptied Co2 bottles for some strange reason they never figured out?

Best part is having Co2 fights you can't breathe as the trigger in the throat

blocks the diaphragm from functioning. "Jamie wants big boom!". What did Karri have, 5 kids at once? Dang she was big, a hoot also with that smile, note her tatoo?

I have one of these below, a Vortex Cooler model 721 NEMA 12 but a pig consuming air, for free a must toy. http://www.vortexair.biz/Cooling/VortexCooler/NEMA12/nema12.html

What?

50' of 3/8" copper bent around a paint can, rubber washing machine hose (has the female garden hose fitting preattached, I just cut it off the other end), and some clear plastic tubing. It works.

Old thread but it's like the "show us your kegerator" thread. It shouldn't ever die and is just a compilation of greatness.

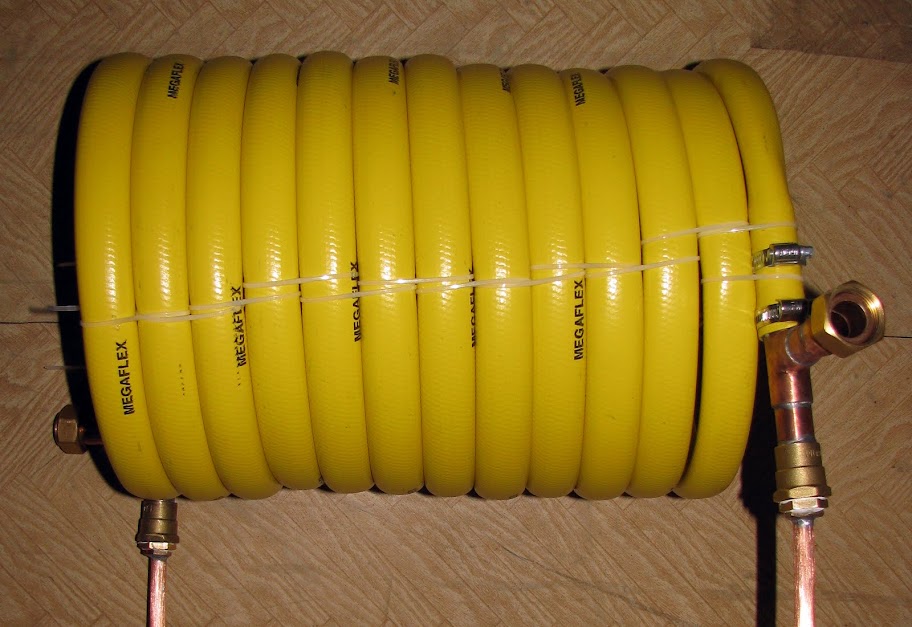

Here is my attempt at a 50' 1/2" refrigeration tubing chiller...

can I pump thru the cfc and back to the boil kettle to whirlpool, then drain into fermenter? Is anyone else doing this? Or is the chance of infection too great whirlpooling after the wort is chilled, if you guys think I can pull this off I plan on using my old ic as a prechiller

Enter your email address to join: