agrazela

Well-Known Member

I see many keezer builds online using pink foam board insulation inside the collar. I'm planning to use this because I have a bunch left from another project.

In the area where the shanks go, a lot of times I see that the builder just leaves a "blank spot" (no insulation). Or perhaps cuts rounds out of the insulation big enough to install the locknut to the collar (like in this pic, and what I'm thinking of doing...though sadly, not nearly this many taps! ) :

Either of those seems like you'd lose some insulation value. Maybe that's just not a big deal?

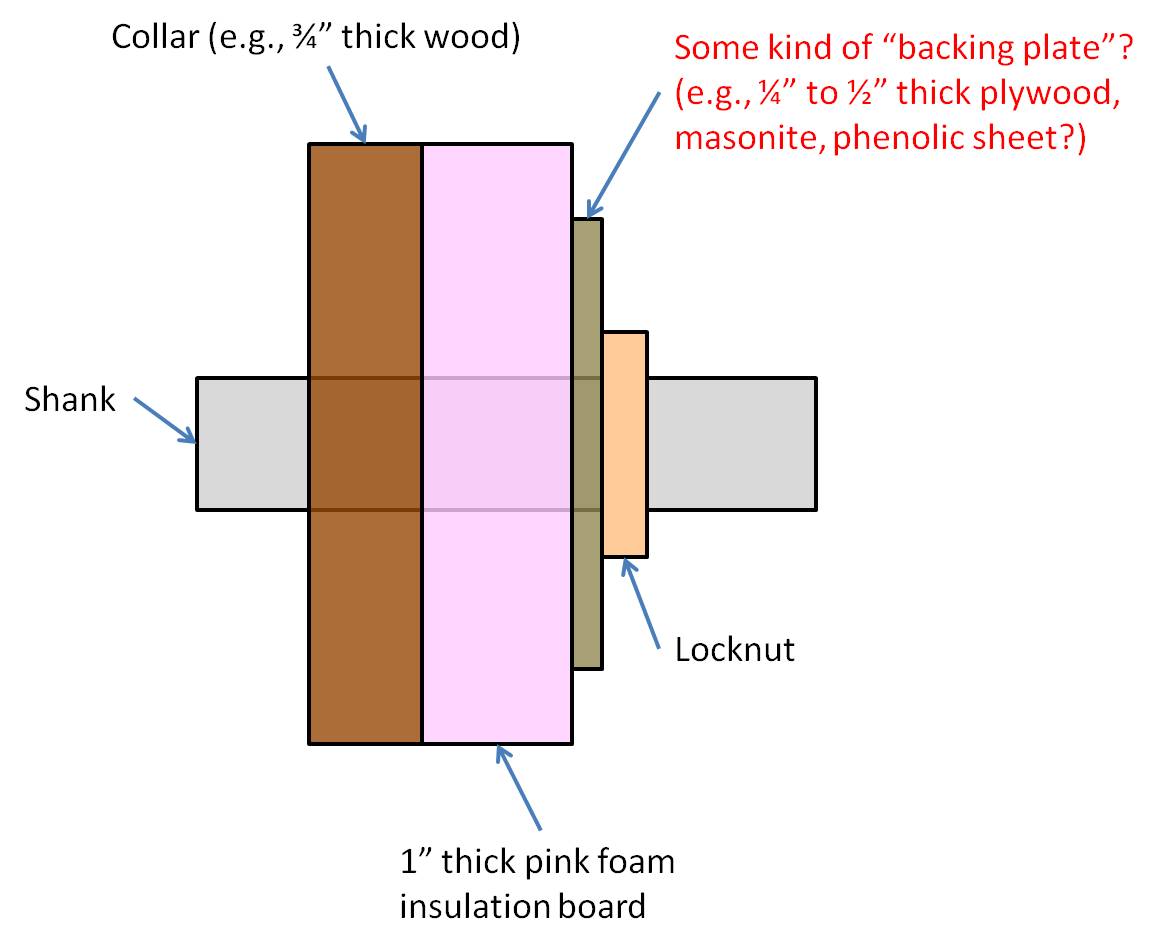

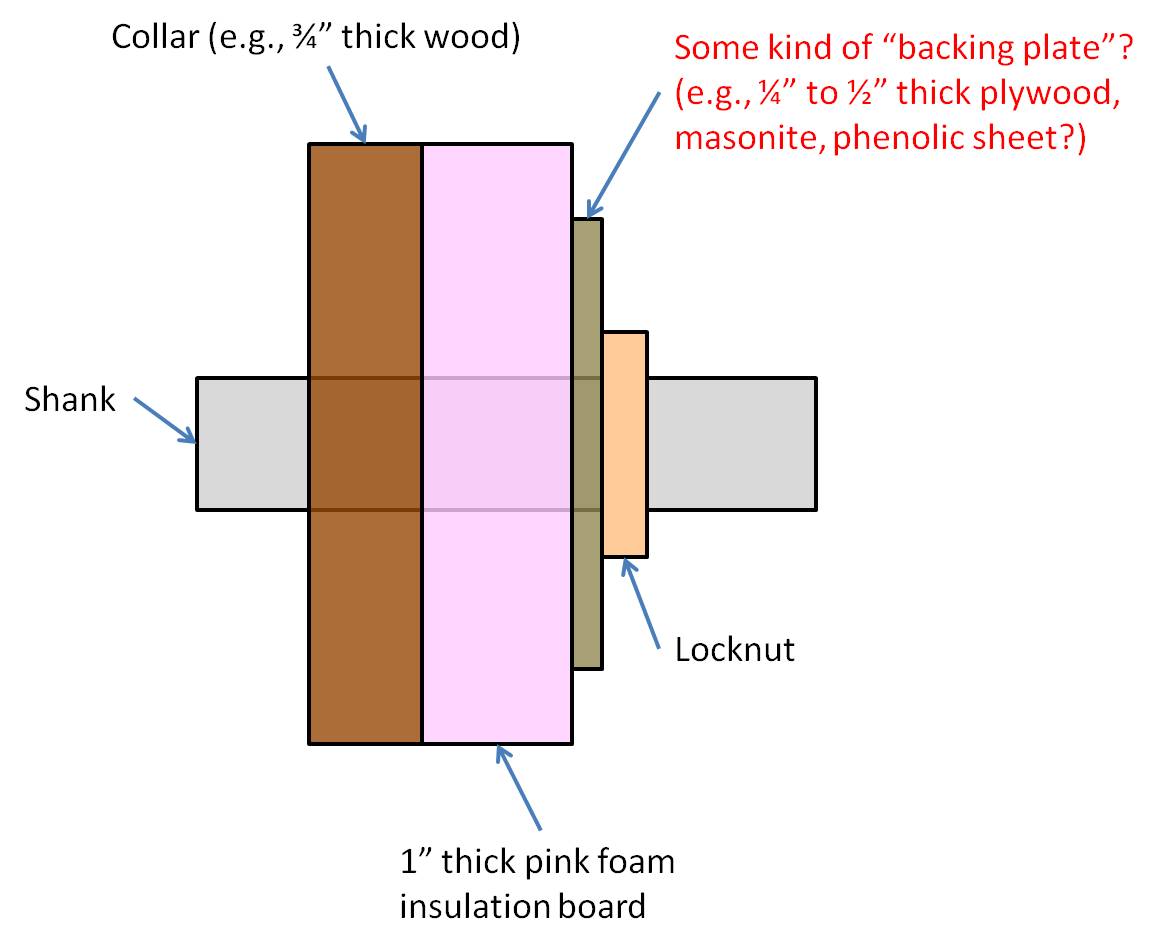

BUT, is there anyone boring through the pink foamboard just big enough for the shank's diameter, then using some sort of backing plate (made from: plywood, or Masonite, or phenolic sheet, or perhaps just giant fender washers, or ???), THEN the locknut? (See my attached drawing for illustration)

Seems like that'd maximize insulation value...though my concern would be crushing down the insulation and/or constantly having to re-tighten the lock nut(s)?

In the area where the shanks go, a lot of times I see that the builder just leaves a "blank spot" (no insulation). Or perhaps cuts rounds out of the insulation big enough to install the locknut to the collar (like in this pic, and what I'm thinking of doing...though sadly, not nearly this many taps! ) :

Either of those seems like you'd lose some insulation value. Maybe that's just not a big deal?

BUT, is there anyone boring through the pink foamboard just big enough for the shank's diameter, then using some sort of backing plate (made from: plywood, or Masonite, or phenolic sheet, or perhaps just giant fender washers, or ???), THEN the locknut? (See my attached drawing for illustration)

Seems like that'd maximize insulation value...though my concern would be crushing down the insulation and/or constantly having to re-tighten the lock nut(s)?