Wish I had taken more/better pics, but here's what I have.

This was taken before I added the second CO2 line. The first CO2 line terminates at the input to the 1:6 manifold; I had to use an elbow at the manifold input as the turn would have been too sharp for the Tygon tubing. The beer gas line is over at the right side; it just pokes through a grommet and ends in a flare fitting.

The second CO2 line (again, not shown) is just above the nitro line and also just pokes through the liner with a grommet. My intention was/is/? to add a 1:2 manifold to that line as I often have a couple of sprightly carbed beers on tap (I run the original CO2 line pressure at ~11 psi and the second line at ~16 psi or higher, depending) but there are days I think a double or triple bank of secondary regs might be the better move. So I'm on the fence

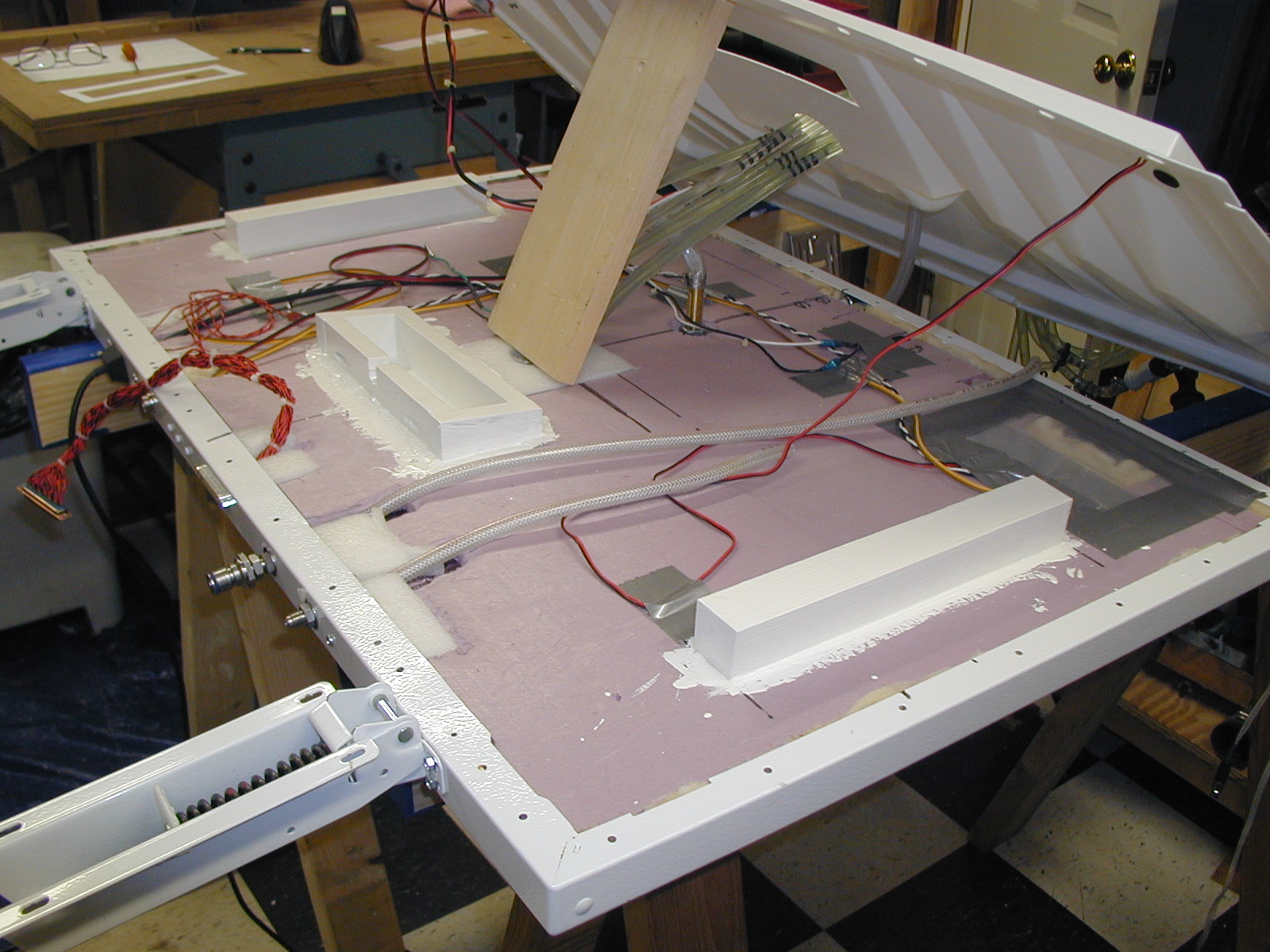

So here's the lid. Surprisingly the freezer came with just a batt of 2" fiberglass insulation stuffed in the lid (my old keezer had foamed-in-place insulation). After tossing that I lined the lid with two layers of high-R rigid foam board. Then I carved out slots for the two wooden risers and epoxied them to the lid sheet metal. The riser on the far side is what the 1:6 manifold is screwed into, the near side riser would be where the second manifold or secondary regulator gang would attach. The box in the middle is for all of the flow meter and temperature sensor plugs and jacks. Not seen (as it's at the bottom of all that foam) is the large section of 3/4" plywood epoxied to the lid to receive the tower mounting screws and keep the lid from distorting when the lid is opened.

You can see the two gas lines coming through the back edge. The third line went in between the first two. The threaded brass stub just under the beer lines is from the drip tray and runs to a catch bottle inside the keezer.

The trickiest bit to all of that was getting the position and height of all the wood pieces right so they would just touch the convoluted lid liner once it was in place. But even with all that going on I was able to keep the dome light fully functional (winning!

)

Hope this gives you some ideas!

Cheers!