lgxg

Well-Known Member

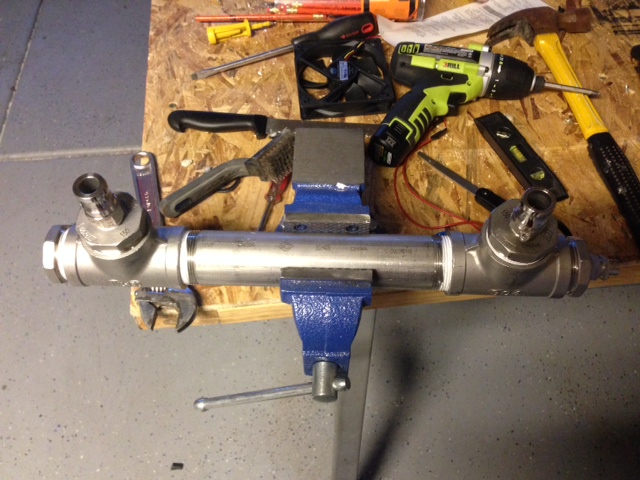

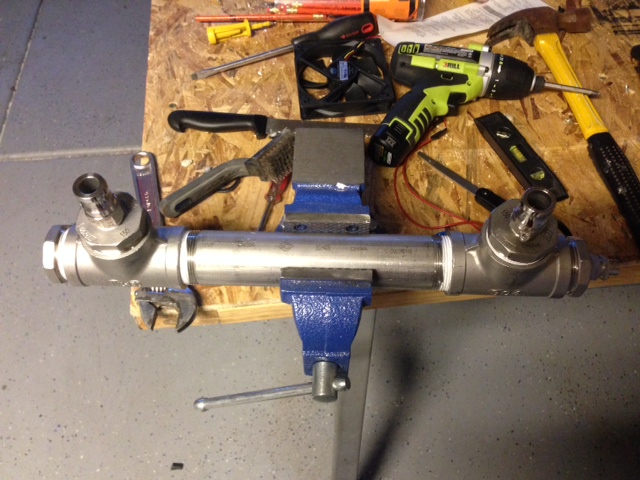

Here is my setup-

operating on 120v, PID controlled RIMS

pre-owned BobbyM/Brewhardware.com pre-triclover setup

4inch rtd

previous owner had a short 1500W ultra low density element - it's rusted a bit

i was thinking of putting in a 4500W LOW (instead of ultra low) density element. this will run at 120 - for a small amp. this one is quite a bit longer - 10 inches instead of 4.5 on the old one. this would be slower ramp up time, but would give me a little more room when operating on a 15 amp circuit.

Some of my thoughts about using this different element was based on what I read in this thread:

https://www.homebrewtalk.com/f51/electric-heating-element-rust-prevention-172928/index5.html

See post 46 and 48

that the camco LOW density elements have a different coating that may be more rust resistant.

when i stick in a tape measure down the element side of the pipe, there's 14 inches before i hit the RTD.

Would it be ok to have a 4 inch gap between element and RTD vs the ~9 inch gap with the old element?

Thanks for the help!

operating on 120v, PID controlled RIMS

pre-owned BobbyM/Brewhardware.com pre-triclover setup

4inch rtd

previous owner had a short 1500W ultra low density element - it's rusted a bit

i was thinking of putting in a 4500W LOW (instead of ultra low) density element. this will run at 120 - for a small amp. this one is quite a bit longer - 10 inches instead of 4.5 on the old one. this would be slower ramp up time, but would give me a little more room when operating on a 15 amp circuit.

Some of my thoughts about using this different element was based on what I read in this thread:

https://www.homebrewtalk.com/f51/electric-heating-element-rust-prevention-172928/index5.html

See post 46 and 48

that the camco LOW density elements have a different coating that may be more rust resistant.

when i stick in a tape measure down the element side of the pipe, there's 14 inches before i hit the RTD.

Would it be ok to have a 4 inch gap between element and RTD vs the ~9 inch gap with the old element?

Thanks for the help!