FuzzeWuzze

I Love DIY

That's a good question Fuzze, it must be for a reason, or just the way they like to install them....It's fine with me though it works great!

John

Maybe Kal or someone else will come in and throw down some knowledge

That's a good question Fuzze, it must be for a reason, or just the way they like to install them....It's fine with me though it works great!

John

by convention, black goes on the gold terminal. the silver terminal is traditionally for a neutral but in this application, the red conductor is landed on the silver screw. it doesn't matter either way for a 240v load with no neutral but panel fabricators are used to putting black on gold.

by convention, black goes on the gold terminal. the silver terminal is traditionally for a neutral but in this application, the red conductor is landed on the silver screw. it doesn't matter either way for a 240v load with no neutral but panel fabricators are used to putting black on gold.

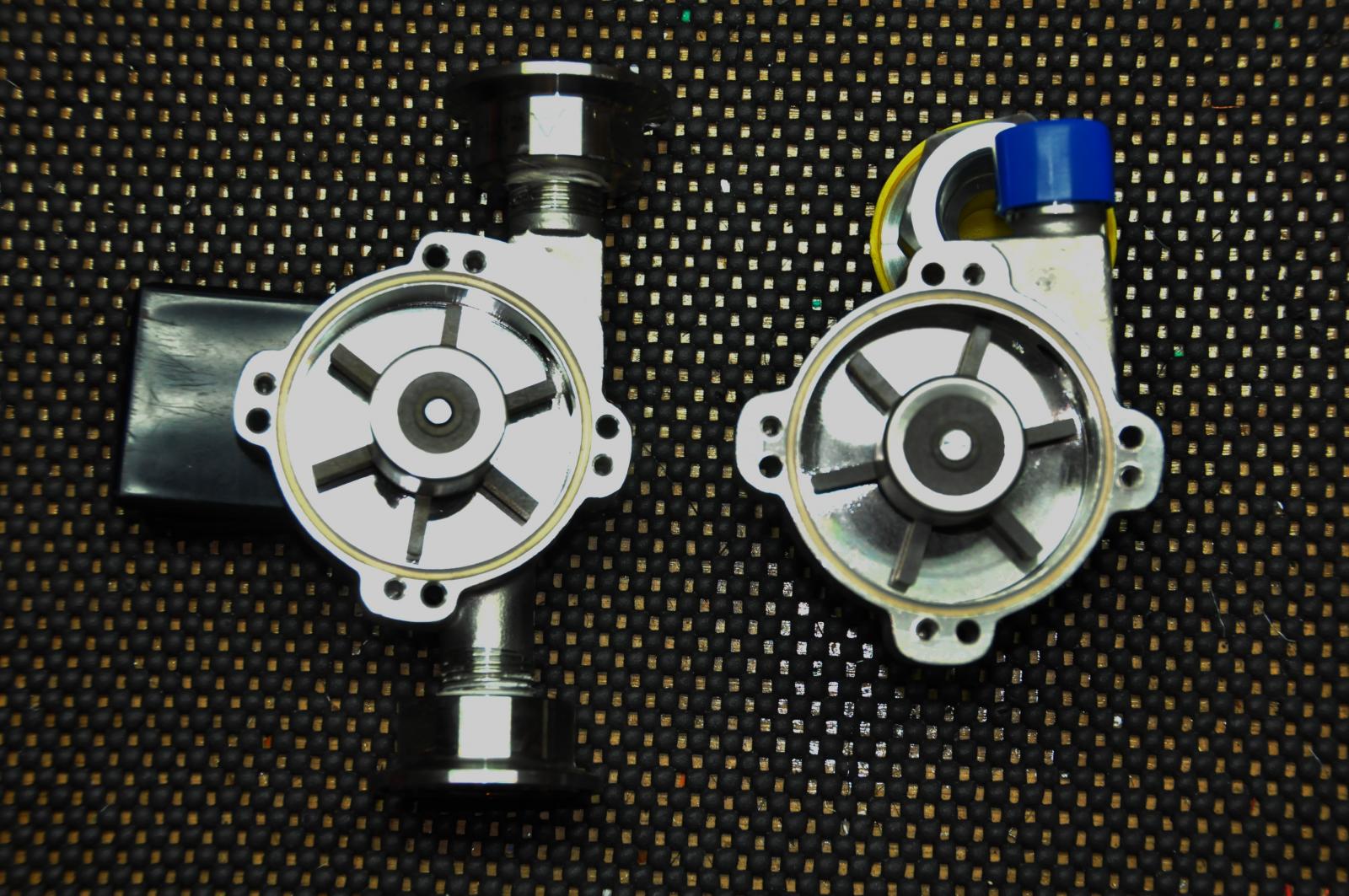

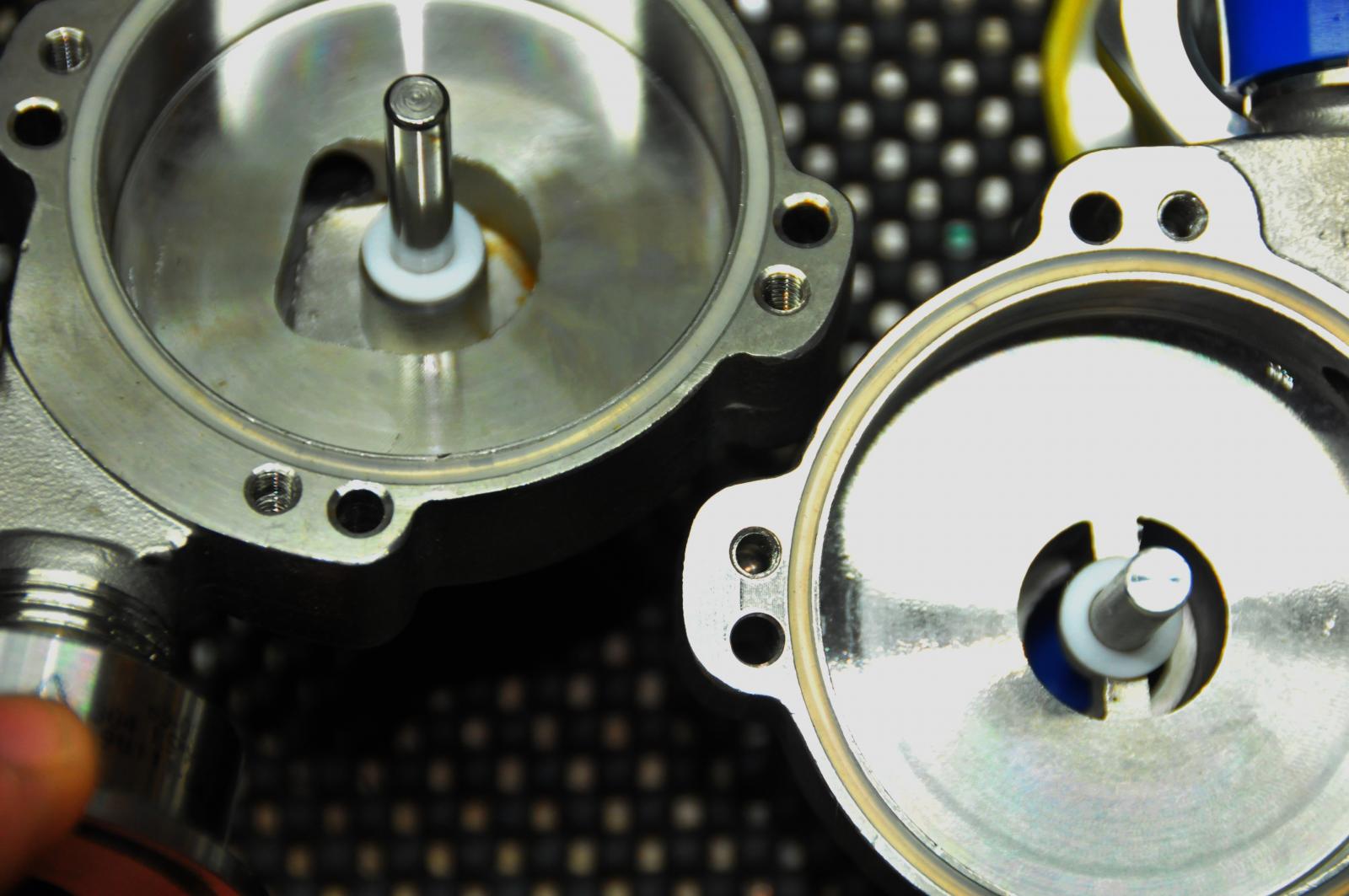

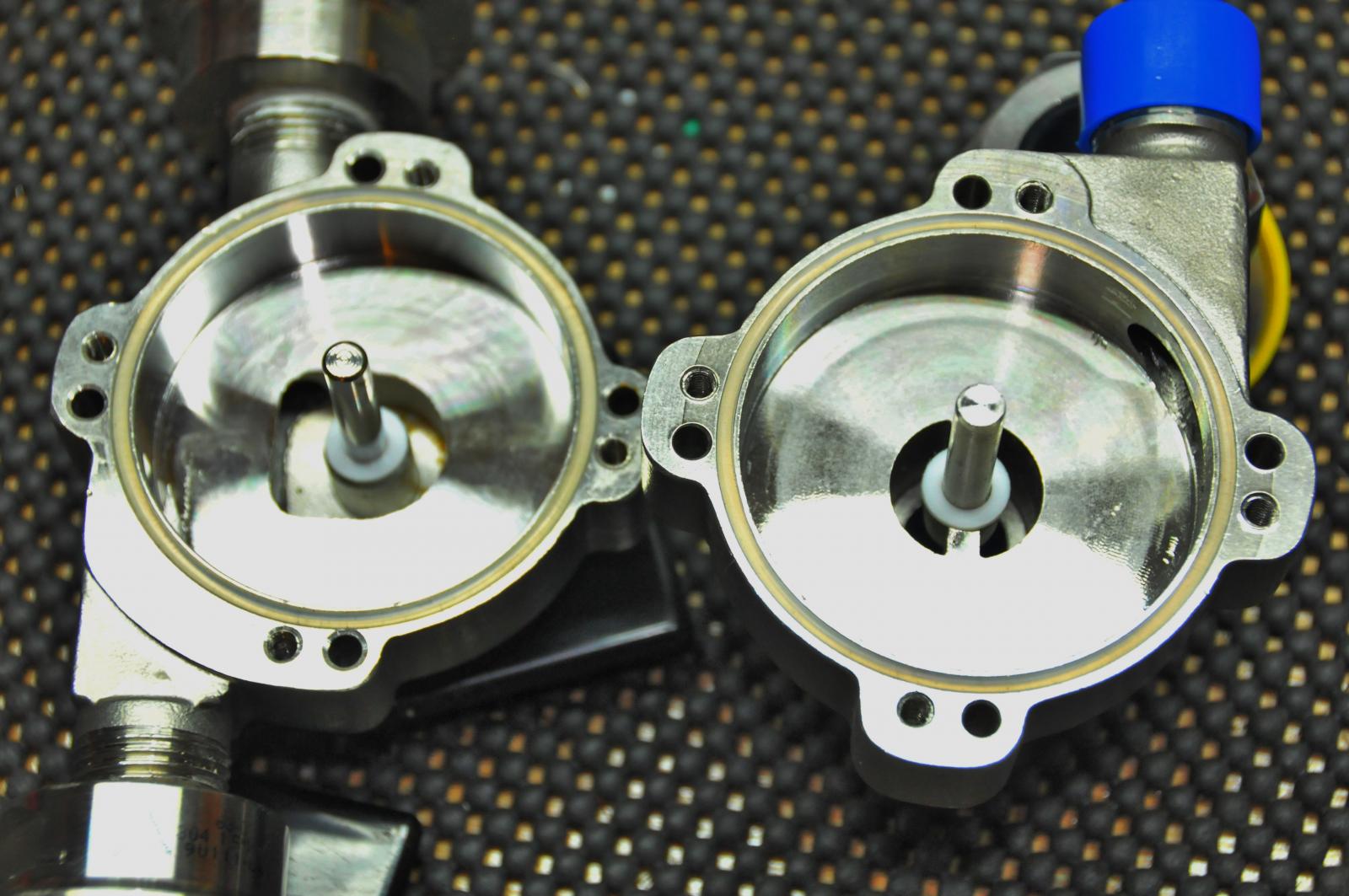

Yup! This is what I've always pushed in the pump article of my brewery build instructions: Get the center inlets. They'll save you lots of headaches.All I can say is if you are building this type of herms system do yourself a favor and get the center inlet pump heads and save yourself some headaches!!

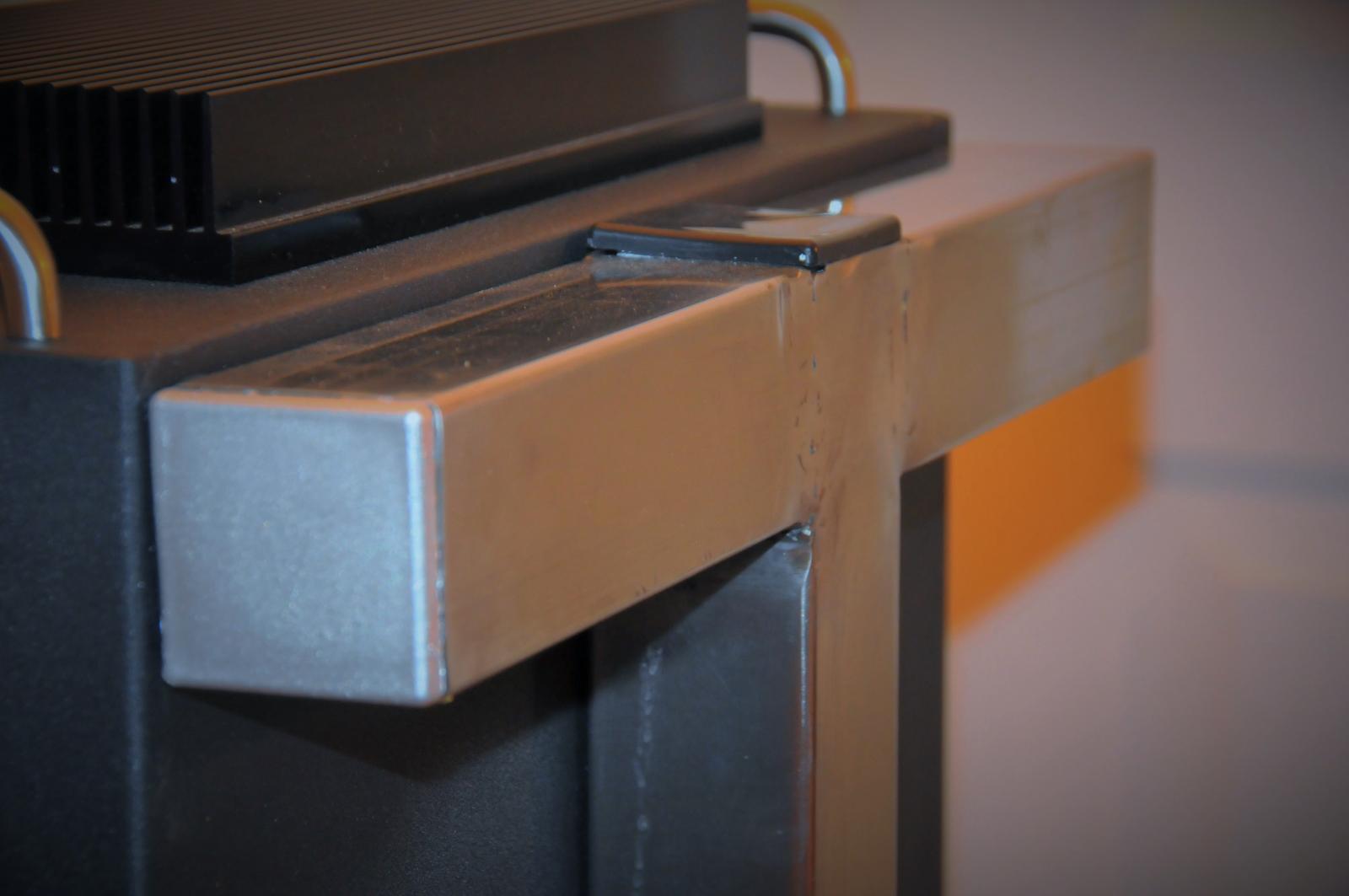

bark at me about the control panel stand! i may need to do something similar...

bark at me about the control panel stand! i may need to do something similar...

Pretty cool. Pretty damn cool.

I used "Bar Keepers Friend" to clean up the keggles. They look so much better with all the smudges and streaks gone. I really should polish them to a mirror finish, but I heard it's such a pain......

Did you use a specific technique to clean up the keggles? By hand or with some tools?

I'm looking to do something similar, but unfortunately haven't figured out a decent way to do this? Any suggestions?

Hope this helps...

I kinda dig the matte finish.

It definitely does help point me in a direction, as I didn't even have a clear path until this. I appreciate the information!

Man your system is awesome! I've already showed the wife. I can't wait until we get our own place, and build something like this.

Seriously gorgeous setup. Your hard work and craftsmanship is apparent! Very nice.

Enter your email address to join: