You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

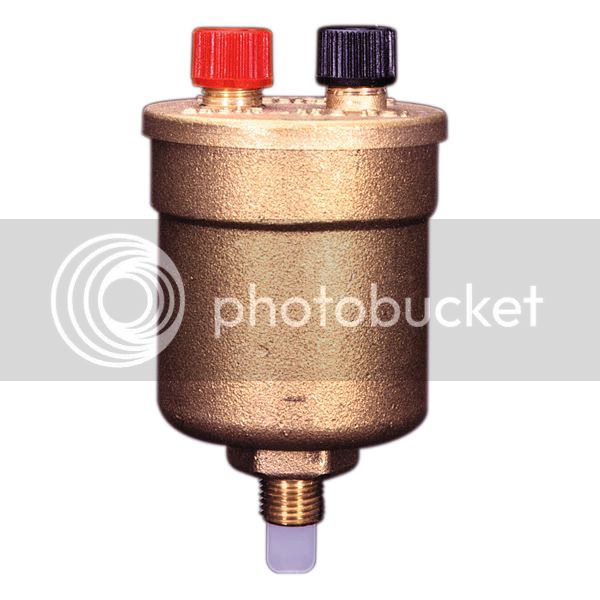

Priming a March with an 'autovent'

- Thread starter Yorg

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Anyone have a Grainger part number -- or direct link -- for the 1/2" autovent? Not finding it on their search.

here: HD SUPPLY WATERWORKS

5144 West 73rd Street

Chicago, IL 60638-6614

(708) 728-9793

call them up and tell them you need them to order a Watts FV-4 1/2" for you.

if they won't do it let me know and I'll make a phone call and get you setup.

-=Jason=-

-=Jason=-

I just got off the phone with Watts and they said to mount the vent as close as possible to the pump output. They stated that the preferred installation is like the way Flowmaster has it installed instead of mounting it in a tee in the output line.

alowell

Well-Known Member

I just did the same thing with a cross off my pump outlet, works like a dream. I used the 1/2" FV-4. I'll try and get pics up soon

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

In a past life doing aquarium stuff, we routinely put a wye check valve immediately after the output the pump. This would keep the pump flooded. Would this work in a brewing application, or would it just be too much of a pain to keep clean?

I've been trying to figure out why I get air in my system with the autovent. Mine is install like Rocky's above. I get sputtering and air in mine. When I remove autovent and plug opening it works fine with bleeder valve.

Right now I am feeding the inlet with quick connects that have a lower flow rate than the hard plumbing in my system. Could it be that the autovent sucks air in because it is not getting enough flow to the inlet?

Right now I am feeding the inlet with quick connects that have a lower flow rate than the hard plumbing in my system. Could it be that the autovent sucks air in because it is not getting enough flow to the inlet?

alowell

Well-Known Member

Where is that vacuum breaker tab? Mine seems to be doing the same thing.

I too just built a 2 tier hermes system, hard piped. All 1/2 in copper. zero problems with priming. my pump (1 of 2 LG 3-hc-md ) is at the lowest point in the system. The first output in my outlet manifold goes to a 1/2 id hose via hose barb. It drops to below the pump and to the front of the stand. DO NOT restrict on your inlet side of your pumps. For my inside sculpture i switched to 5/8 ID hose on the inlet side. If the smallest diameter is on the inlet side of your pump, you will ALWAYS have priming issues. There should be little reason for one of these valves IMO.

alowell

Well-Known Member

I guess it all depends if people have priming issues with their hard-piped systems. It is a case-by-case thing...I agree that it is not a necessity in ALL systems.

I guess it all depends if people have priming issues with their hard-piped systems. It is a case-by-case thing...I agree that it is not a necessity in ALL systems.

IMO, it should not be necessary in ANY properly designed system, hard piped or not. Cletsup has is right and very much so.

IMO, it should not be necessary in ANY properly designed system, hard piped or not. Cletsup has is right and very much so.

So you don't even use a bleeder valve?

Basically, It's just an amusing substitute for a bleeder valve.

Plus, some of us have space restrictions in our brewing area, or other restrictions that keep us from having a "properly designed" system.

Cheers.

Where is that vacuum breaker tab? Mine seems to be doing the same thing.

I had the old model, which they don't sell anymore. It had a tab at the bottom.

I think the replacement part either has the vacuum breaker tab in the same location, or for the 1/2"npt model, it is enclosed.

alowell

Well-Known Member

So you don't even use a bleeder valve?

Basically, It's just an amusing substitute for a bleeder valve.

Plus, some of us have space restrictions in our brewing area, or other restrictions that keep us from having a "properly designed" system.

Cheers.

Agreed, I have an autovent on one of my pumps, but not on the other. It is a good substitute for the bleeder valve when you don't want to spew hot liquid on yourself out of the bleeder valve. The autovent is a good option for those that didn't perfectly engineer their rigs and don't feel like ripping out pipes and refitting things. All a matter of preference. Dgonza9, I have to say that I do like a bleeder valve on the pump between the MT and BK. It allows for sampling while sparging.

The bleeder valve is the 1/2 ball valve connected to the first outlet on the manifold. If you have 10 gal of water in your HLT, you should have no problems simply opening the lowest point in the system. Also allows you to drain the system almost completley. As far as properly designed. Water flows down hill. The lowest point will be your trap. If you have space problems your probably not hard piped. Just change the locations of your pumps. That head pressure is kinda important. And again, most importanty. Watch your restrictions.

So you don't even use a bleeder valve?

Basically, It's just an amusing substitute for a bleeder valve.

Plus, some of us have space restrictions in our brewing area, or other restrictions that keep us from having a "properly designed" system.

Cheers.

No. I don't use an autovent gizmo. Yes, your system is quite amusing. No one can take that away from you.

Sawdustguy

Well-Known Member

No. I don't use an autovent gizmo. Yes, your system is quite amusing. No one can take that away from you.

It's interesting that you criticize people for using an autovent which is less expensive and easier to use than the manual valve you use to prime your pump. It doesn't really make sense when in actuality they do the same thing.

I never realized how much fun it would be watching a thread like this with all the "flat earth" experts on brew rig design, this is better than a TV soap opera.

Sawdustguy

Well-Known Member

I never realized how much fun it would be watching a thread like this with all the "flat earth" experts on brew rig design, this is better than a TV soap opera.

+1,000,0000 Kevin, I am not blowing smoke up your behind but honestly, you are one of the few around here that I consider an expert. Too many people criticize others for not doing it the way they think they should. I guess it's human nature because I have been guilty of it a time or two.

It's interesting that you criticize people for using an autovent which is less expensive and easier to use than the manual valve you use to prime your pump. It doesn't really make sense when in actuality they do the same thing.

Not really. The cost is low for either, so that's not even worth discussing. I don't agree that the autovent is any easier to use. It requires about 2 seconds to prime with the valve and It's rare that I have to do it more than once or twice per session. The dump valve can also be used to draw wort samples. Can't do that with an Autovent. So, don't get me wrong. I would never try to tell someone that they should not use an Autovent. My point was that a simple dump valve works perfectly if you have the plumbing set up right. I think this forum would be completely worthless if all we saw was continuous fellatio. I don't see how one could have a contrary opinion while at the same time avoiding the appearance of unkind criticism. Need we be so thin skinned? I don't think so.

Besides, who sets up a plumbing system without a dump valve? how does one intend to drain their system if there are traps in it. Isn't sanitation the number one rule of thumb. you gotta get all that stuff outa there. If you try and set up a way to drain your rig you will have a valve @ the lowest point. problem solved. I can actually fill my mash tun up to the same level as the HLT without turning on the pump, priming the pump in the process. All the same principals apply to flexible tubing. its easier, because you can move your equipment. Ball valve same price an autovent. not really. needed the dump valve anyways...

big_al_in_k-zoo

Well-Known Member

Just gotta say "thanks" to O.P. for this idea. I ordered a 1/4" Version and tested it out yesterday. Works like a champ. (Pumping water so far, that is)

Just gotta say "thanks" to O.P. for this idea. I ordered a 1/4" Version and tested it out yesterday. Works like a champ. (Pumping water so far, that is)

I too have the 1/4" version mounted on a cross above pump outlet. I'm not sure how great mine is. I usually have to turn the pump off at least once to get the prime going.

Does yours prime right away?

Secondly, I thought the plastic tabs that activate the float are almost too large for the 1/4" opening. Mine seem to get twisted and therefore may not vent properly. I had two of these and removed one. The tab was quite twisted. With my other one, I was getting flow, but a bit low and I gave the autovent a turn with a wrench a bit tighter. It almost seemed to "slip" and I heard air hiss out of it. Flow suddenly increased?

Any ideas what is going wrong? For me, this thing has been a disappointment and wasted a lot of my time. I'm glad it's working better for other's. Here's my setup. It's unfinished in this photo, but you get the idea.

Thanks for idea. You're right about the pump being the lowest point, but with the union the best I can do is an elbow there. Walter at March pumps says this is the optimal configuration for the pump.

Anyway, mine works okay. I just turn the pump off once. The air vents and I'm good to go. I might try putting the pump on a 1.5" coupling. The spec sheet says that if you have a coupling 1.5x the size of the output and input pipes it can vent while pumping as well.

Anyway, mine works okay. I just turn the pump off once. The air vents and I'm good to go. I might try putting the pump on a 1.5" coupling. The spec sheet says that if you have a coupling 1.5x the size of the output and input pipes it can vent while pumping as well.

I bought an autovent. I was surprised to see the warning that came in the box with it. Saying that California requires the consumer be told that this product contains chemicals know to cause cancer and birth defects.

Not sure if I should be worried by this or not. Doesn't even say what chemicals

Not sure if I should be worried by this or not. Doesn't even say what chemicals

Sawdustguy

Well-Known Member

I bought an autovent. I was surprised to see the warning that came in the box with it. Saying that California requires the consumer be told that this product contains chemicals know to cause cancer and birth defects.

Not sure if I should be worried by this or not. Doesn't even say what chemicals

That warning is on the Autovent because it is made from brass which we all know is incredibly toxic and will burn your eyes out if you so much as look at it while you are in California. If you cross the border into Nevada, you will be perfectly safe and suffer no ill effects at all.

That warning is on the Autovent because it is made from brass which we all know is incredibly toxic and will burn your eyes out if you so much as look at it while you are in California. If you cross the border into Nevada, you will be perfectly safe and suffer no ill effects at all.

I thought it might be something like that. Thanks

shiny...

http://www.ecoheats.com/1_2_automatic_air_vent_for_solar_4086_prd1.htm

will this do the same thing?

http://www.ecoheats.com/1_2_automatic_air_vent_for_solar_4086_prd1.htm

will this do the same thing?

It will do the same thing as the Watts brand auto air vent, just in a larger and shinier package with a pipe connection the same size as the pump outlet.

And 4 times the price.

I paid $7 for my 1/2" watts autovent in brass or bronze what ever its made out of.

just sayin'

call up any watts distributor and ask them to order it for you.

http://www.watts.com/pages/findARep.asp

select water safety and flow control

select your state

??????????

Profit

now mind you I ordered this though work at my discount any other rep would probably sell a watts 1/2" FV-4 for $15-$20 or there abouts.

-=Jason=-

just sayin'

call up any watts distributor and ask them to order it for you.

http://www.watts.com/pages/findARep.asp

select water safety and flow control

select your state

??????????

Profit

now mind you I ordered this though work at my discount any other rep would probably sell a watts 1/2" FV-4 for $15-$20 or there abouts.

-=Jason=-

Awesome. Subscribed.

RobbyBeers

Well-Known Member

- Joined

- Jan 16, 2009

- Messages

- 163

- Reaction score

- 4

I've been following these threads about autovents, so I recently put a stainless T on the outlet of my pump and added one (the newer Watts model). I could never really get it to work to my satisfaction. It would prime, but not dependably...it would vent air, but it would never create a good siphon. When it did work, it spewed foam, which was less than ideal.

I've decided to change out the autovent in favor of a ball valve. A bleeder valve is a simple enough setup, and I can control when and where I dump my beer.

Of course this could all be obscure to my setup, just sayin...

I've decided to change out the autovent in favor of a ball valve. A bleeder valve is a simple enough setup, and I can control when and where I dump my beer.

Of course this could all be obscure to my setup, just sayin...

Sawdustguy

Well-Known Member

I've been following these threads about autovents, so I recently put a stainless T on the outlet of my pump and added one (the newer Watts model). I could never really get it to work to my satisfaction. It would prime, but not dependably...it would vent air, but it would never create a good siphon. When it did work, it spewed foam, which was less than ideal.

I've decided to change out the autovent in favor of a ball valve. A bleeder valve is a simple enough setup, and I can control when and where I dump my beer.

Of course this could all be obscure to my setup, just sayin...

I think your fooling yourself. If the Autovent vented the air and it still did not prime dependably I doubt the ball valve will help much either. I would bet you have an air leak somewhere.

I've been following these threads about autovents, so I recently put a stainless T on the outlet of my pump and added one (the newer Watts model). I could never really get it to work to my satisfaction. It would prime, but not dependably...it would vent air, but it would never create a good siphon. When it did work, it spewed foam, which was less than ideal.

I've decided to change out the autovent in favor of a ball valve. A bleeder valve is a simple enough setup, and I can control when and where I dump my beer.

Of course this could all be obscure to my setup, just sayin...

I went thru something similar. It was a leak. I removed my autovent for a while while I figured it out. I'm surprised at how well it did work now that it's gone. Bleeder valve is very effective, but I sometimes have to play with it, spill wort a bit, etc.

I'm likely going back to the autovent. I may try and mount it on a larger tee. Instructions say that if you mount it on something 1.5 times the diameter of your system it can vent while circulating. Seems a lot of work/expense, though to save yourself from pushing a button and turning your pump off to allow the air to vent. LOL. I'm doing it!

Similar threads

- Replies

- 4K

- Views

- 363K

- Replies

- 24

- Views

- 4K

- Replies

- 8K

- Views

- 1M