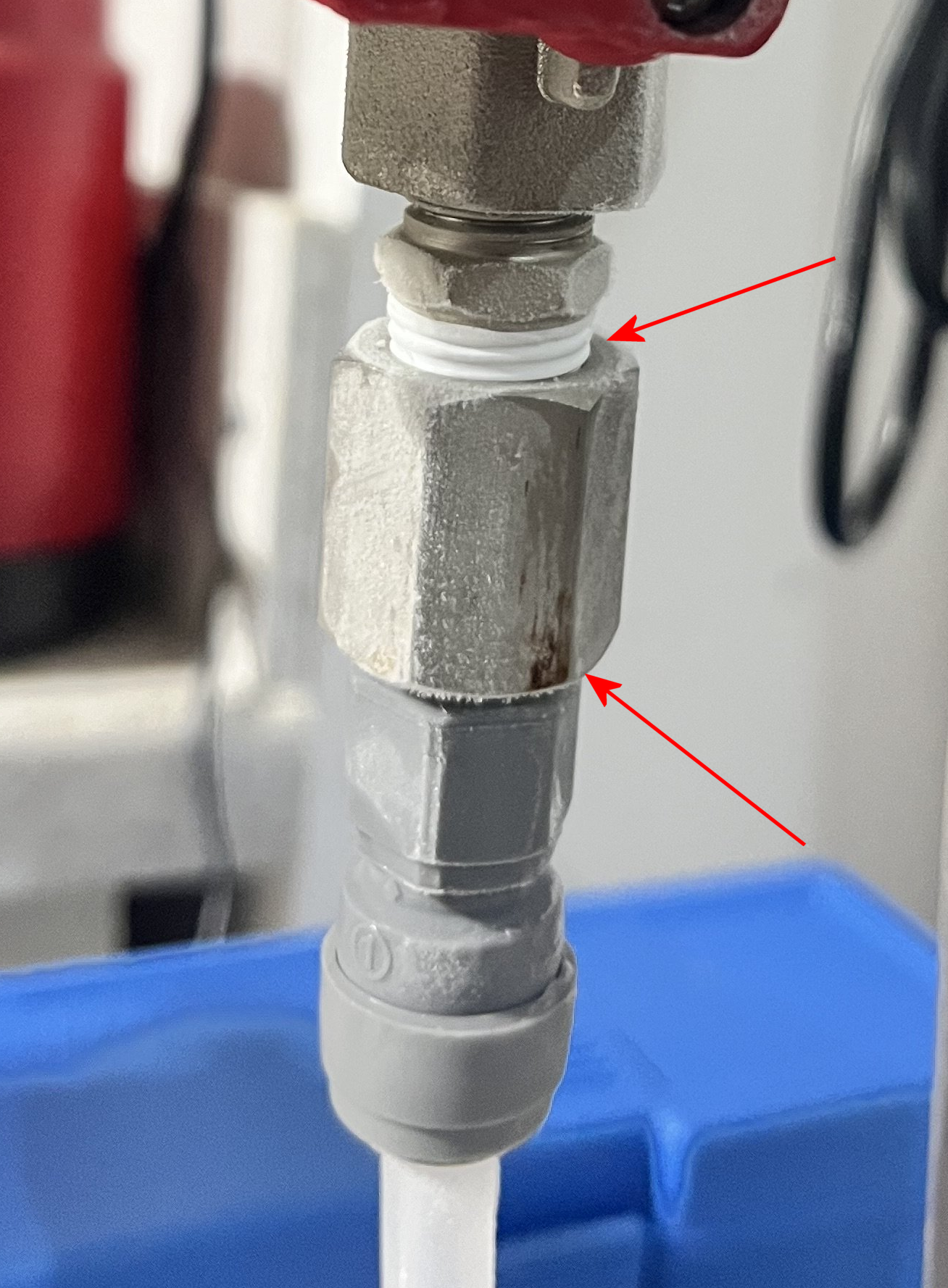

I completed my first closed pressure transfer today. I experienced an issue I have a question about. From the regulator about 6” down the gas line froze nearly solid and I lost way more CO2 than expected. Everything else went to plan. This regulator did not previously have a leak and it is used often. After it warmed back up, I raised the pressure back to 10+ (I pushed at 2) and it worked. I found no leaks.

Is it possible that the regulator leaked because of the low pressure I was pushing? Did I have it set lower than necessary?

Is it possible that the regulator leaked because of the low pressure I was pushing? Did I have it set lower than necessary?