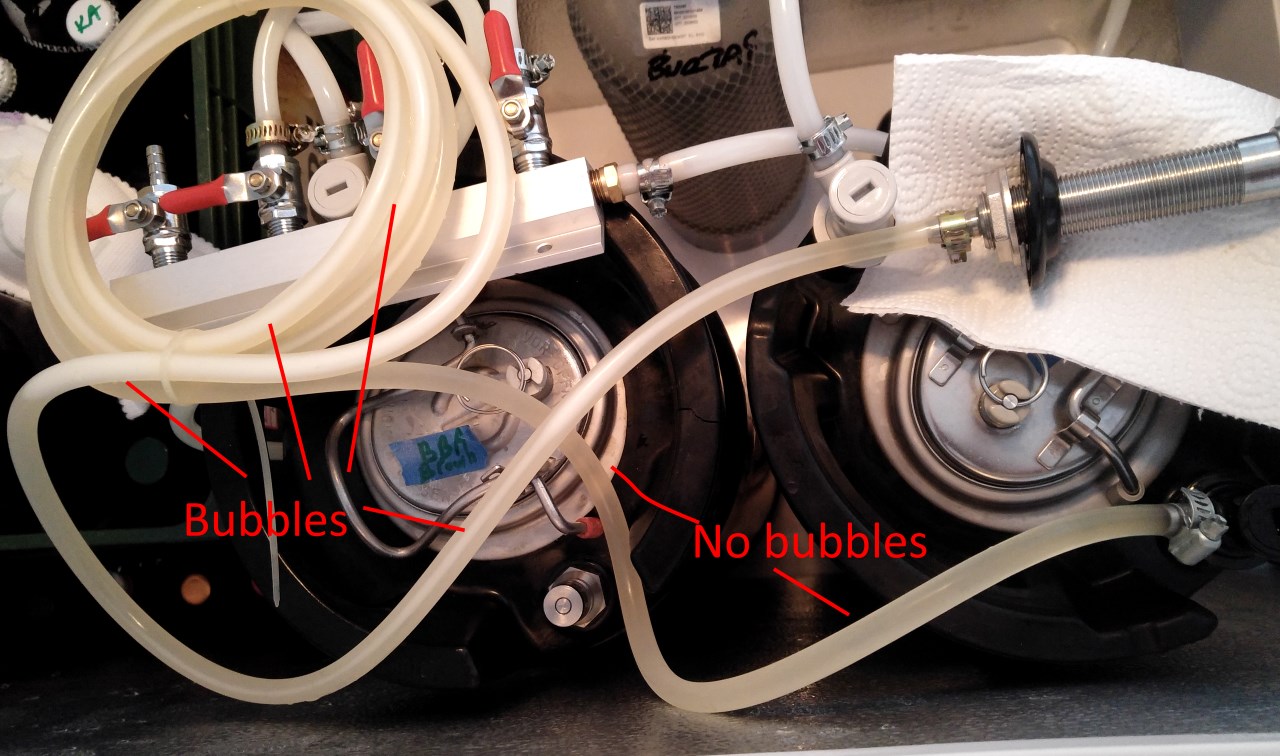

This is an example of the problem:

(Don't mind the perlick on the keg, I'm going to build a collar this weekend )

)

I was experiencing the same problem with picnic tap, was thinking that it will go away with a proper faucet, but no luck.

Here is my setup :

12 psi constant pressure applied to kegs for 1.5 week, which is also the serving pressure

~1/4" (6mm) ID-9.5 feet (3m) beer lines

Tried upping the pressure to 16 psi, same problem

Tried lowering the pressure to 8 psi, again same problem.

Filling the glass takes approximately 5 seconds.

What should I try next to get proper pours? No matter what I try 90% of the glass is foam. I'm getting pretty wasted while trying different pressures and pouring methods

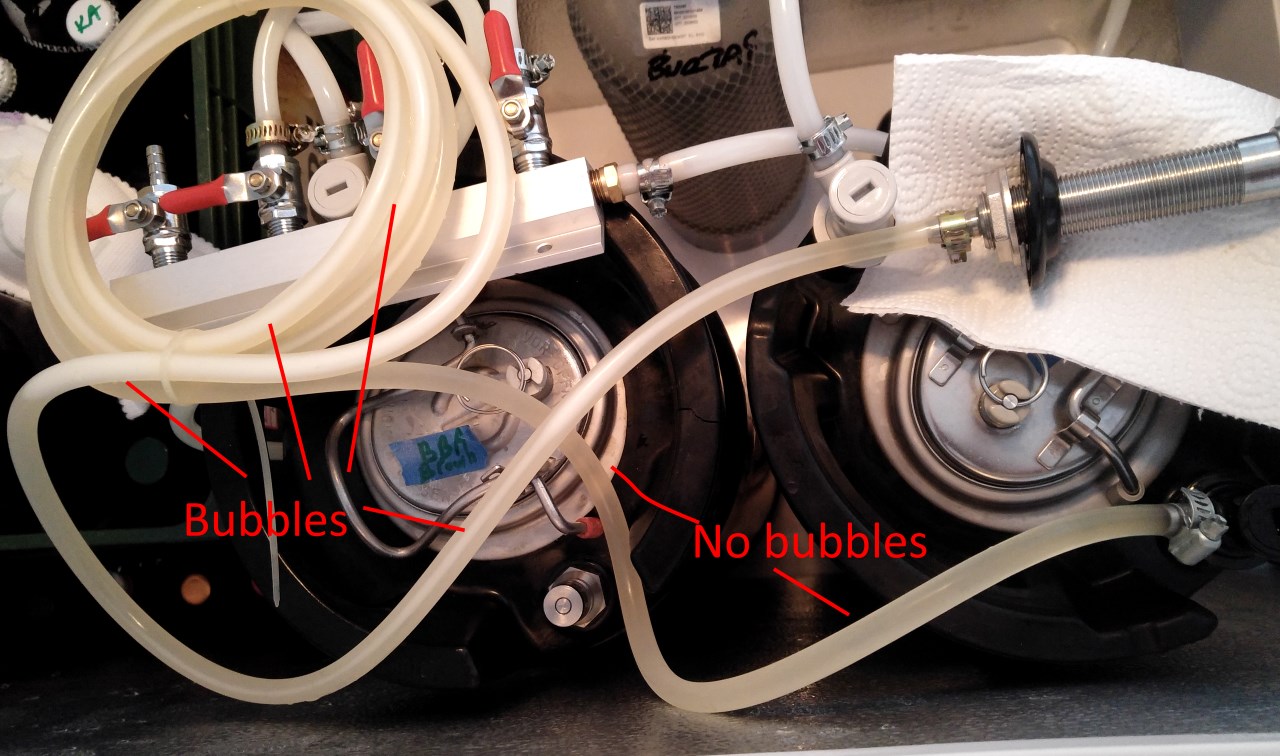

(Don't mind the perlick on the keg, I'm going to build a collar this weekend

I was experiencing the same problem with picnic tap, was thinking that it will go away with a proper faucet, but no luck.

Here is my setup :

12 psi constant pressure applied to kegs for 1.5 week, which is also the serving pressure

~1/4" (6mm) ID-9.5 feet (3m) beer lines

Tried upping the pressure to 16 psi, same problem

Tried lowering the pressure to 8 psi, again same problem.

Filling the glass takes approximately 5 seconds.

What should I try next to get proper pours? No matter what I try 90% of the glass is foam. I'm getting pretty wasted while trying different pressures and pouring methods