Ok, so I didn't want to put this in the DIY Forum mainly because it really isn't beer related. Though it is a big checkmark off of my to do list before I can get to the indoor brewery! I also posted this on my blog here if you are interested.

As I have alluded to in a few other blog posts, much of my all of my free time the past couple months has been devoted to taking down our old and unsafe deck, and constructing a brand new one! It has been a really fun project even thought it has taken 5 times longer than I expected and roughly 30% more than I budgeted...buy once, cry once. I normally keep my blog strictly related to beer brewing and consuming, but wanted to provide everyone with proof of why I have been so absent in the homebrewing and blogging world, and use it as an excuse to show off my skills.

Without further ado:

BEFORE

The old deck had a lot of problems. When we bought the house I had inspected it and new it was almost beyond saving. The fact that we didn't touch it at all over the harsh winter insured there was no saving it. The previous structure was two 12x12 decks at different levels. The stairs from the upper level to the lower level took up almost 25% of the lower deck. There were also two built-in benches on the lower deck, which ended up being the most secure part, ha!

(These pics from the house listing make it look much better than it actual was, but you get the point)

Old Deck Issues

Anyone interested on the safety concerns form the old structure - The old deck attached to the house rim joist with a few lag screws installed into one 2x8 right through the siding. A lot of these screws had rusted. The deck frame consisted of 6x6 posts with 2x8 boards bolted to the sides. This means the entire weight of the structure was being supported by the rusty lag screws at the house ledger and the bolts on the posts. To code today, the beams must rest on top of the posts. I later find out during demolition that (see picture below) the posts weren't even connected to a cement footing, or burried into the ground! They were just sitting on the ground....wow. Once we cut off the beam, the posts fell right over.

New Deck

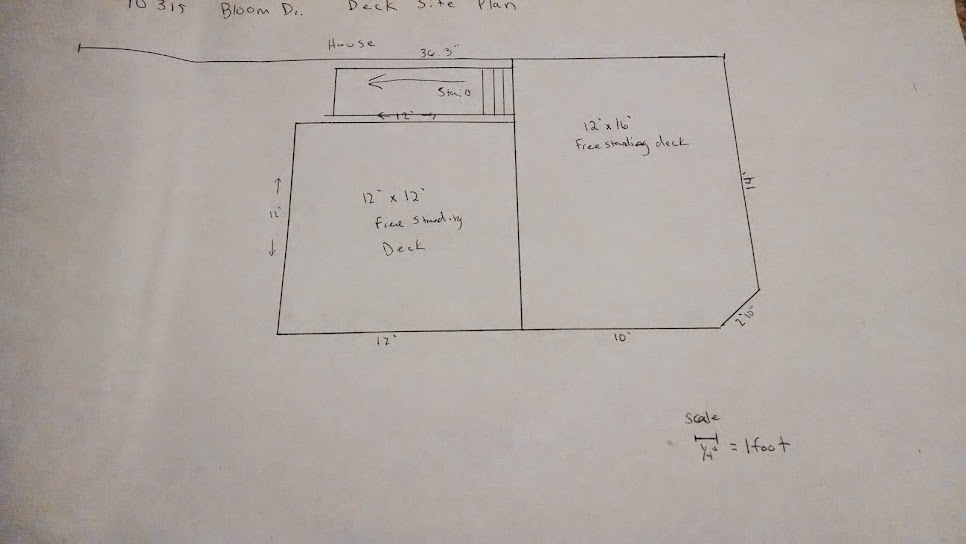

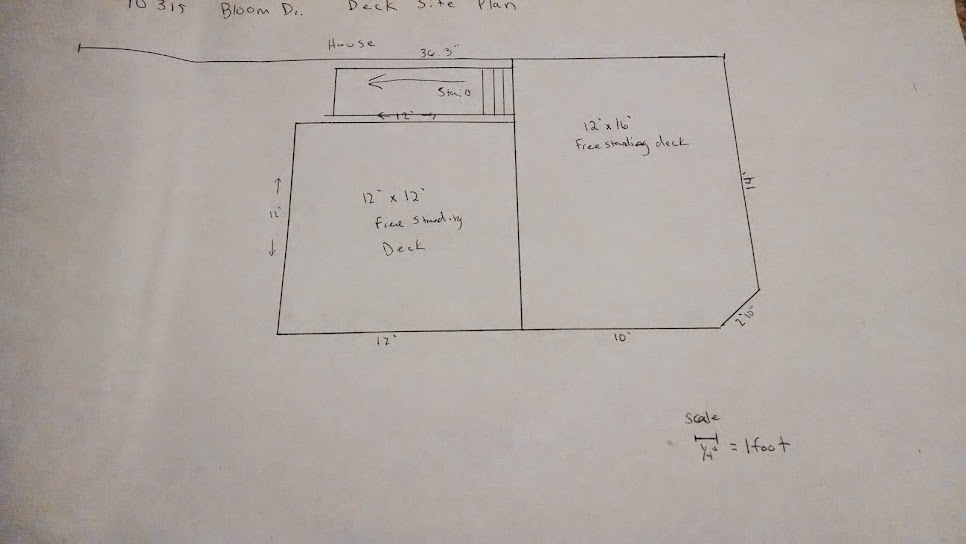

For the new deck I had to go to the county office and get a permit. I made I sure I was there right as they opened at 7:30am. This process would have been really quick and smooth had I not been right behind someone representing a fence and deck company. This lady was getting 9 permits...so it was as if 9 people were in front of me! So much for being there right when they opened! The way my county has things set up, if a homeowner is going to build a deck by themselves, they don't need to submit official constructions plans as long as they follow the county deck packet to a "T." Because of this, my end design would need to be framed a little differently than a normal deck with my proposed layout to meet the county requirements. I confirmed with the county that as long as my two frames each met the requirements, I could run the decking over both structures. I will end up having a 12x16 and a 12x12 framed deck at the same level for 336 total square feet!

Deck Plan - The angle on the bottom right was not allowed as I was required to have a perfect rectangle

As I have alluded to in a few other blog posts, much of my all of my free time the past couple months has been devoted to taking down our old and unsafe deck, and constructing a brand new one! It has been a really fun project even thought it has taken 5 times longer than I expected and roughly 30% more than I budgeted...buy once, cry once. I normally keep my blog strictly related to beer brewing and consuming, but wanted to provide everyone with proof of why I have been so absent in the homebrewing and blogging world, and use it as an excuse to show off my skills.

Without further ado:

BEFORE

The old deck had a lot of problems. When we bought the house I had inspected it and new it was almost beyond saving. The fact that we didn't touch it at all over the harsh winter insured there was no saving it. The previous structure was two 12x12 decks at different levels. The stairs from the upper level to the lower level took up almost 25% of the lower deck. There were also two built-in benches on the lower deck, which ended up being the most secure part, ha!

(These pics from the house listing make it look much better than it actual was, but you get the point)

Old Deck Issues

Anyone interested on the safety concerns form the old structure - The old deck attached to the house rim joist with a few lag screws installed into one 2x8 right through the siding. A lot of these screws had rusted. The deck frame consisted of 6x6 posts with 2x8 boards bolted to the sides. This means the entire weight of the structure was being supported by the rusty lag screws at the house ledger and the bolts on the posts. To code today, the beams must rest on top of the posts. I later find out during demolition that (see picture below) the posts weren't even connected to a cement footing, or burried into the ground! They were just sitting on the ground....wow. Once we cut off the beam, the posts fell right over.

New Deck

For the new deck I had to go to the county office and get a permit. I made I sure I was there right as they opened at 7:30am. This process would have been really quick and smooth had I not been right behind someone representing a fence and deck company. This lady was getting 9 permits...so it was as if 9 people were in front of me! So much for being there right when they opened! The way my county has things set up, if a homeowner is going to build a deck by themselves, they don't need to submit official constructions plans as long as they follow the county deck packet to a "T." Because of this, my end design would need to be framed a little differently than a normal deck with my proposed layout to meet the county requirements. I confirmed with the county that as long as my two frames each met the requirements, I could run the decking over both structures. I will end up having a 12x16 and a 12x12 framed deck at the same level for 336 total square feet!

Deck Plan - The angle on the bottom right was not allowed as I was required to have a perfect rectangle