I will be pressure fermenting an IPA in a keg in a week or two and my plan is to ferment and serve out of the same keg -- the keg will be sealed upon pitching, never opened until it's serving days are spent.

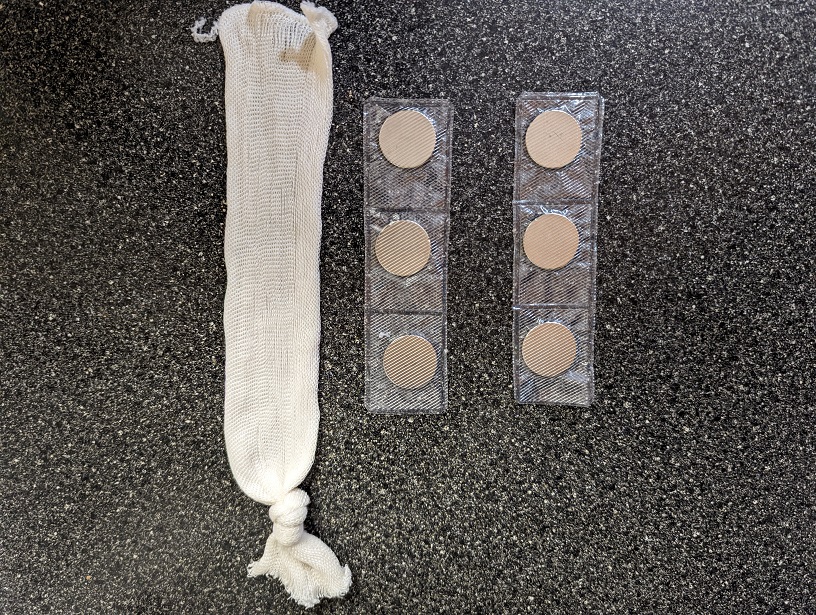

I considered the magnet drop method for dry-hopping, but I am not sure that I want the hops sitting in the serving keg for 2-3 months (if it lasts that long).

Would adding the hops that I planned for dry hopping to the whirlpool be worthwhile? Or will the hops sitting in the keg for the life of it be ok?

The recipe calls for 3oz of citra at flameout and 3oz of citra for dry hops. Would 6oz at flameout work?

Thanks

I considered the magnet drop method for dry-hopping, but I am not sure that I want the hops sitting in the serving keg for 2-3 months (if it lasts that long).

Would adding the hops that I planned for dry hopping to the whirlpool be worthwhile? Or will the hops sitting in the keg for the life of it be ok?

The recipe calls for 3oz of citra at flameout and 3oz of citra for dry hops. Would 6oz at flameout work?

Thanks