pizzaman

Well-Known Member

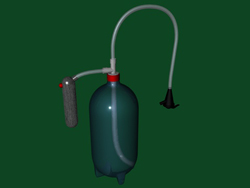

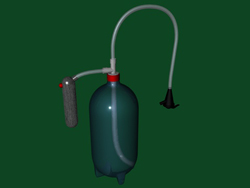

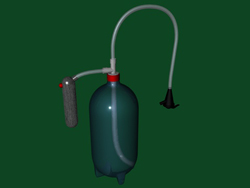

Here's what I'll be working on tomorrow:

I've looked everywhere for those metal stems and can't seem to find one locally. I tried lowe's, home de-pot, ace, even autozone.

As far as your question, aside from the 10 different reasons I've given in previous posts, I just thought of another one. My *ahem* brewing method is 1 week in primary and 1 week in the bottle. Scoff and curse all you want but it works and it's damned fine beer.

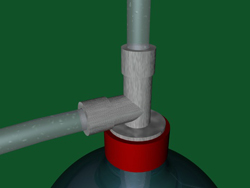

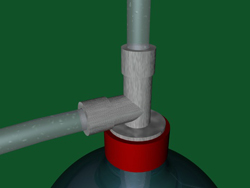

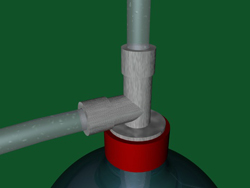

Here's a pic of the regulator, anyone think this will/won't work for regulating psi of co2 as long as I get the valves hooked up properly?

Here's a pic of the regulator, anyone think this will/won't work for regulating psi of co2 as long as I get the valves hooked up properly?

Just because the gauge reads from 0-160 doesn't mean that's the maximum inlet pressure that the regulator is rated for. It could be higher, or could be lower. A gauge is just a gauge. I could screw a gauge that reads 0-1000 psi into some crappy little regulator, that doesn't mean it's going to work.

And you're going to use this to regulate high pressure CO2 from a refillable paintball canister?

Maybe I'm missing something here, but high pressure CO2 is in the neighborhood of 700-800 psi if I remember correctly.

I have just confirmed as many before me have, that a 5 gallon water bottle will not hold suitable pressure for use as a keg. The lid had no seal at all, after wrapping the threads in threading tape it was able to hold a seal, however the bottom of the bottle began to bulge out as the psi reached a mere 5. Not sure how denny was able to do it, maybe he had a different water bottle. Either way, I have ditched that idea, and am rethinking the design.

If I hadn't decided to check back up on this thread you'd have blown up that regulator and possibly caused serious harm to yourself or others. Take a step back, what is it that you don't like about the corny keg system? What are you trying to do better?

You're right Schlenk! It was a team effortPhlyanPan - You can't take all the credit. I was warning him too.

The point remains, things are being played with that aren't fully understood.

The point remains, things are being played with that aren't fully understood. Pizzaman. I bought 3 kegs for $15 each and a regulator for about $50 and the hoses, gas & beer for about $30. If you shop around you can get the stuff for a corny set-up for not too much dough.

Gas bottles can be found pretty cheap at a local gas places like Praxair or whatever is common in your neighborhood.

I've been looking on craigslist and ebay constantly for over a month now and haven't found anything in my price range yet. I wish I knew someone that is currently or used to be into brewing to get these things. I got most of my current brew setup from my father in law who used to brew occasionally, but unfortunately he never got into kegging. As of right now I have a co2 tank and adapter, I'm gonna keep looking for a used co2 regulator that is meant for kegging, maybe I'll just get lucky.

Enter your email address to join: