Bigtex2884

Member

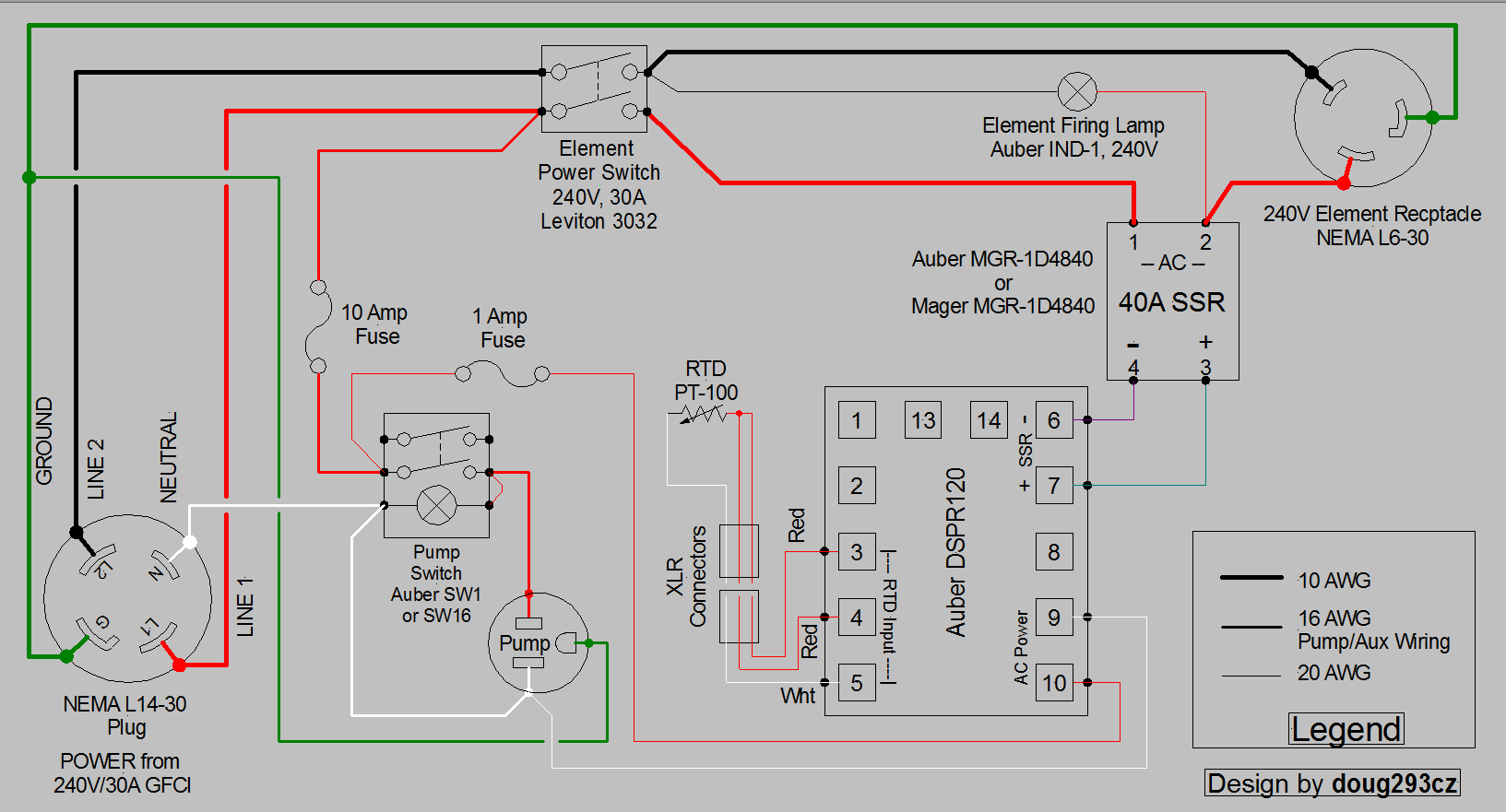

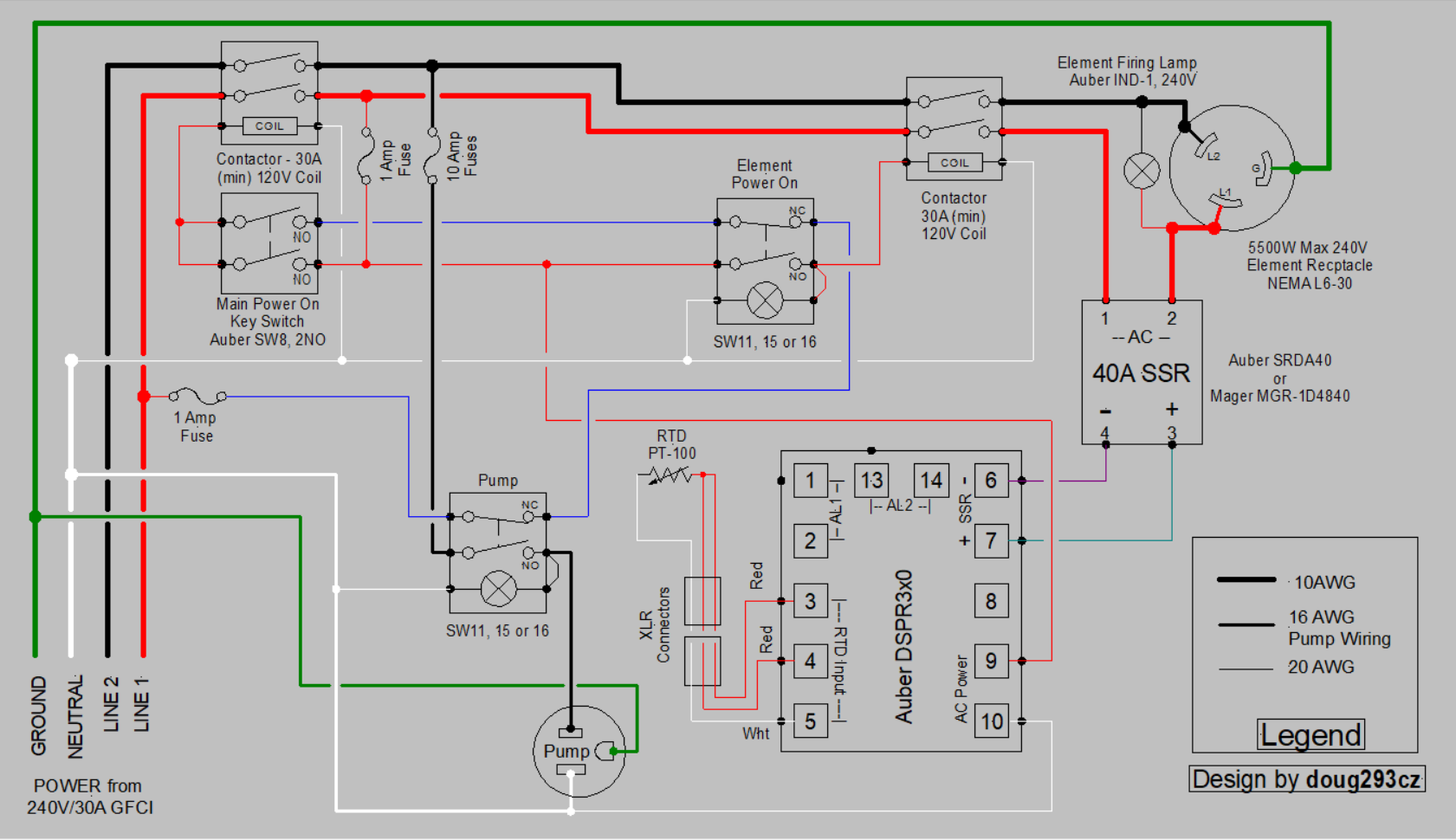

Im looking for a simple PID wiring diagram. I recently just installed a 240v 30a GFI breaker and ran a 4 prong (dryer) outlet into my garage (red,black,white,ground). Im going to run one 5500w heating element. I used 10/3 for my wiring.

I was hoping someone could link me to or submit a diagram to create a PID. I was going to get a. TA4-SSR and a 40a ssr-da with heatsink.

I was hoping someone could link me to or submit a diagram to create a PID. I was going to get a. TA4-SSR and a 40a ssr-da with heatsink.