I am new to this. Successful making a batch of Belgium Whit so I decided to build another batch. A friend advised me to add 3 cups of sugar just prior to bottling to increase the alcohol content of the final product. Si did that, added 3 cups of sugar while the wart was still hot, so it would dissolve well. There is way too much carbonation. Open a bottle and it may or may not foam out the top. When I could successfully pour it was too carbonated to enjoy. Unfortunately this caused the batch to go down the drain. Is this the way to increase alcohol content or what went wrong?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to brewing, excessive carbonation

- Thread starter akpolaris

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

treacheroustexan

Well-Known Member

Not sure if I'm reading this correctly. Three cups is way too much sugar to add before you bottle. If you want to increase your alcohol content, add the sugar during the boil. If you're adding it during the boil and not directly before bottling, make sure your gravity is stable/the beer is done fermenting. If you try to bottle while the yeast is still eating away, that will definitely cause over carbonation/bottle bombs.

If you add three additional cups directly before bottling, you will have dangerous bottle bombs all over your house. Not good.

If you add three additional cups directly before bottling, you will have dangerous bottle bombs all over your house. Not good.

The sugar was added immediately after the boil, prior to the carboy going into the closet for about 3 weeks. Not just prior to bottling. I read some other thread and believe the bottles that I opened and experienced excessive carbonation had been refrigerated well over 48 hrs. So add extra sugar during the boil?

treacheroustexan

Well-Known Member

The sugar was added immediately after the boil, prior to the carboy going into the closet for about 3 weeks. Not just prior to bottling. I read some other thread and believe the bottles that I opened and experienced excessive carbonation had been refrigerated well over 48 hrs. So add extra sugar during the boil?

Sorry, your original post said just prior to bottling so it threw me off. Do you have a hydrometer? How much sugar did you add when you bottled it?

Yea after reading my initial post I see that, my bad. I am at work and no records with me. I get home in a week and will try this again with less sugar I guess. I believe that I added 3/4 cup per the instruction s prior to bottling

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

The sugar added before fermentation should not influence the carbonation. It should be eaten pretty quickly by the yeast during the first days of fermentation. However. If you added the correct amount of sugar when bottling, and it's overcarbed you might have bottled before the yeast was finished fermenting out the sugars in the beer, meaning that you'd get carbonation equal to the amount of sugar you added, plus the sugars which weren't eaten by the yeast, this means you bottled to early.

To be honest I wouldn't "add sugar to increase alcohol content". It throws off the recipe, and it might taste weird. If you want more alcohol, brew a recipe which initially will yield you more alcohol. It's better to drink beer whcich tastes good (just drink more of it if you want a good buzz), than have to force down a beer which is sub par-taste wise, but higher in alcohol.

To be honest I wouldn't "add sugar to increase alcohol content". It throws off the recipe, and it might taste weird. If you want more alcohol, brew a recipe which initially will yield you more alcohol. It's better to drink beer whcich tastes good (just drink more of it if you want a good buzz), than have to force down a beer which is sub par-taste wise, but higher in alcohol.

Ok here is another question. When I put the air lock on the 2 batches I have brewed the fermentation has pushed the cap off and expelled a lot of foam making quite a mess. Would running a vent tube into a milk jug or other container with water in it suffice? I work out of town for 2 weeks at a time so what I have done to date is get the batch into the carboy and leave while I am gone. To her credit the wifey has not complained but did mention the beer odor in the closet. The overflow has been onto a towel but I can put the carboy and venting system into a plastic container of some sort to contain it.

Ok here is another question. When I put the air lock on the 2 batches I have brewed the fermentation has pushed the cap off and expelled a lot of foam making quite a mess. Would running a vent tube into a milk jug or other container with water in it suffice? I work out of town for 2 weeks at a time so what I have done to date is get the batch into the carboy and leave while I am gone. To her credit the wifey has not complained but did mention the beer odor in the closet. The overflow has been onto a towel but I can put the carboy and venting system into a plastic container of some sort to contain it.

Yeah, thats called a blowoff tube, if you don't have enough headspace in the carboy you'll get a mess without one. And some yeasts make a lot more krausen (foam) than others. Best case is it just pushes krausen out the airlock and you get a mess on the floor. Worst case is it clogs the airlock, pressure builds up, and you have a messy explosion... theres a story somewhere of a guy brewing in the closet next to the (probably ex now) wives wedding dress.

Put some sanitiser in the water to keep it clean.

flars

Well-Known Member

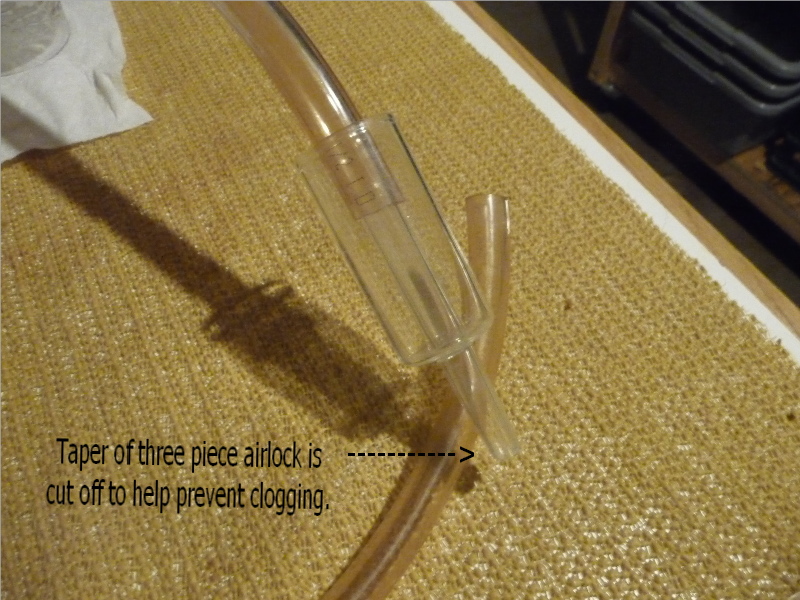

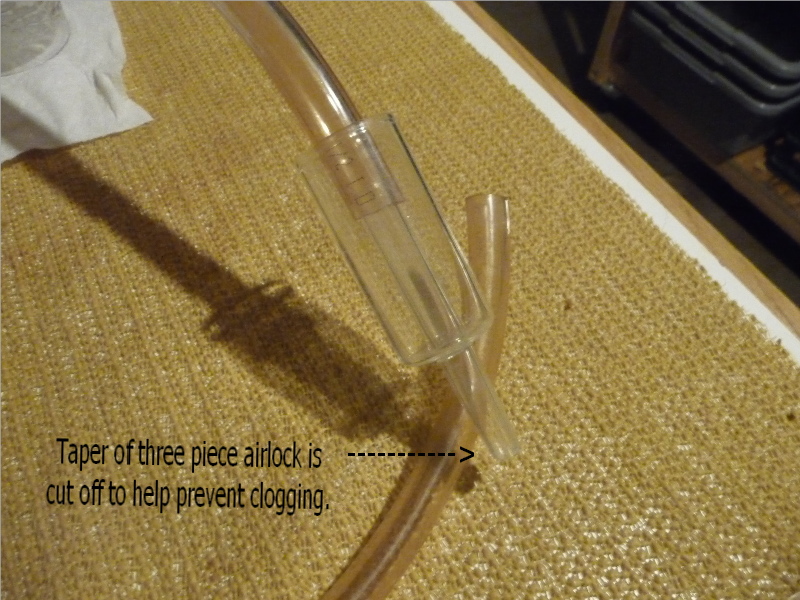

You are describing a blow off tube assembly. They are used all the time when excessive krausen is expected. Have the container holding some sanitizer at the bottom of the fermentor or even lower to prevent any possibility of suck back if there is a change in the beers temperature.

Excess krausen blowing out the air lock can mean the fermentation temperature is too warm causing an over active fermentation. Could also mean the fermentor is on the small side for the volume of wort or some yeasts like WY 3068 always produce a huge krausen.

Here is a picture of an assembly using the main body of a three piece airlock.

Excess krausen blowing out the air lock can mean the fermentation temperature is too warm causing an over active fermentation. Could also mean the fermentor is on the small side for the volume of wort or some yeasts like WY 3068 always produce a huge krausen.

Here is a picture of an assembly using the main body of a three piece airlock.

Another factor to consider is how long the beer had been bottled before you refrigerated it. It takes some days for the tiny hop particles and yeast to settle out. Until they do they are nucleation points for the CO2 to come out of the beer and that causes foaming. To see the effect, pour a glass of 7 UP and drop in a little sugar. It should foam up from that. The recommended time to wait is 3 weeks from bottling and at least 24 hours after that to refrigerate.

So I have a 5 gal carboy fermenting in the closet. Tried a recipe form the store called Anchorage Steam Beer. It will be about 21 days between the time it was put in the closet until I can tend to bottling it. What are the benefits of using malt extract instead of sugar at bottling time?

flars

Well-Known Member

I don't see a substantial benefit to using extract for carbonation. Flavor addition would be negligible with the small amount used.

You have been using volume measures for adding the priming sugars? Weighing the sugar is much more accurate. A good digital scale can cost less than $20.

I use this carbonation calculator for weighing the priming sugar.

https://www.northernbrewer.com/priming-sugar-calculator/

Calculator also gives amounts by volume if the scale purchase is out of reach right now.

The scale is also used for hop additions and weighing bread flour in the kitchen.

You have been using volume measures for adding the priming sugars? Weighing the sugar is much more accurate. A good digital scale can cost less than $20.

I use this carbonation calculator for weighing the priming sugar.

https://www.northernbrewer.com/priming-sugar-calculator/

Calculator also gives amounts by volume if the scale purchase is out of reach right now.

The scale is also used for hop additions and weighing bread flour in the kitchen.

bernardsmith

Well-Known Member

So I have a 5 gal carboy fermenting in the closet. Tried a recipe form the store called Anchorage Steam Beer. It will be about 21 days between the time it was put in the closet until I can tend to bottling it. What are the benefits of using malt extract instead of sugar at bottling time?

Hi akpolaris - and welcome. I guess I am unclear about precisely how much sugar you are adding to prime the bottles. As smellyglove wrote there are two different aspects to yeast and sugar in solution. The first is to make the beer or wine and the second - and this involves precisely the same process but the outcome is very different is to make the beer or wine carbonated. I am sure I am teaching my grandmother how to suck eggs (as the saying goes): When you pitch yeast onto a sugar solution the yeast produce alcohol and CO2. During active fermentation you are really interested ONLY in the alcohol production, and not in the CO2. After active fermentation, that is , when all the sugar has been converted into alcohol you might add a very little more sugar (about 3/4 of ounce per gallon)but this time you are interested ONLY in the amount of CO2 the yeast will produce and you have zero interest in that tiny amount of additional alcohol which is now a bi-product of the CO2 production

My 1st brewing I added 3/4 cup of sugar at bottling time. The 2nd batch, which was over carbonated, I added 3 cups of sugar to the wart prior to fermenting. I mixed it in while the wart was hot prior to cooling it and pitching the yeast. The current batch I have waiting for me to get home I will introduce the 3/4 of priming sugar at bottling time.

View attachment IMG_1263.MOV

View attachment IMG_1263.MOV

myndflyte

Well-Known Member

My 1st brewing I added 3/4 cup of sugar at bottling time. The 2nd batch, which was over carbonated, I added 3 cups of sugar to the wart prior to fermenting. I mixed it in while the wart was hot prior to cooling it and pitching the yeast. The current batch I have waiting for me to get home I will introduce the 3/4 of priming sugar at bottling time.

Ok, but with that overcarbed batch, how much sugar did you add prior to bottling and after fermentation was done? Adding 3 cups of sugar prior to fermenting is not going to affect carbonation. That sugar is going to be eaten long before you bottle.

If you did not add more sugar prior to bottling, then your overcarbed beer is because it wasn't done fermenting.

To me it sounds like we are talking about two different things:

1. Adding "priming" sugar just before bottling to create carbonation

2. Adding sugar into the hot wort to increase alcohol content

The priming sugar I agree with most everyone else here; until you get into specific carbonation levels for specific beer styles, a good rule of thumb is 3.5-4 oz of sugar dissolved (boiled in water/cooled) into the bottling bucket before bottling.

The sugar addition to increase alcohol content is a little different. Depending on your yeast strain, gravity and temperature your yeast may or may not eat all of it. One of the things I do to increase alcohol content is wait until primary fermentation has slowed a bit (3-4 days) then boil sugar/dme in just enough water to moisten, then cool to fermentation temp and then pour it in. You can do this multiple times; you can expect to increase your abv by just under 1% per pound of sugar/dme. This way you dont stress out your yeast at the beginning when there is a lot more sugar to eat.

1. Adding "priming" sugar just before bottling to create carbonation

2. Adding sugar into the hot wort to increase alcohol content

The priming sugar I agree with most everyone else here; until you get into specific carbonation levels for specific beer styles, a good rule of thumb is 3.5-4 oz of sugar dissolved (boiled in water/cooled) into the bottling bucket before bottling.

The sugar addition to increase alcohol content is a little different. Depending on your yeast strain, gravity and temperature your yeast may or may not eat all of it. One of the things I do to increase alcohol content is wait until primary fermentation has slowed a bit (3-4 days) then boil sugar/dme in just enough water to moisten, then cool to fermentation temp and then pour it in. You can do this multiple times; you can expect to increase your abv by just under 1% per pound of sugar/dme. This way you dont stress out your yeast at the beginning when there is a lot more sugar to eat.

3/4 cup added prior to bottling

Ok, but with that overcarbed batch, how much sugar did you add prior to bottling and after fermentation was done? Adding 3 cups of sugar prior to fermenting is not going to affect carbonation. That sugar is going to be eaten long before you bottle.

If you did not add more sugar prior to bottling, then your overcarbed beer is because it wasn't done fermenting.

myndflyte

Well-Known Member

3/4 cup added prior to bottling

Based on that, then I would say that your beer wasn't done with the primary fermentation and that's why that batch is gushing.

Based on that, then I would say that your beer wasn't done with the primary fermentation and that's why that batch is gushing.

Were they all gushing or just a couple? If you didn't mix the dissolved sugar well enough into the beer it's possible you got more sugar in some bottles and less in others.

myndflyte

Well-Known Member

Were they all gushing or just a couple? If you didn't mix the dissolved sugar well enough into the beer it's possible you got more sugar in some bottles and less in others.

Good point. OP said "may or may not foam" so maybe it's more likely the sugar was not evenly distributed before bottling.

Similar threads

- Replies

- 17

- Views

- 643

- Replies

- 3

- Views

- 1K