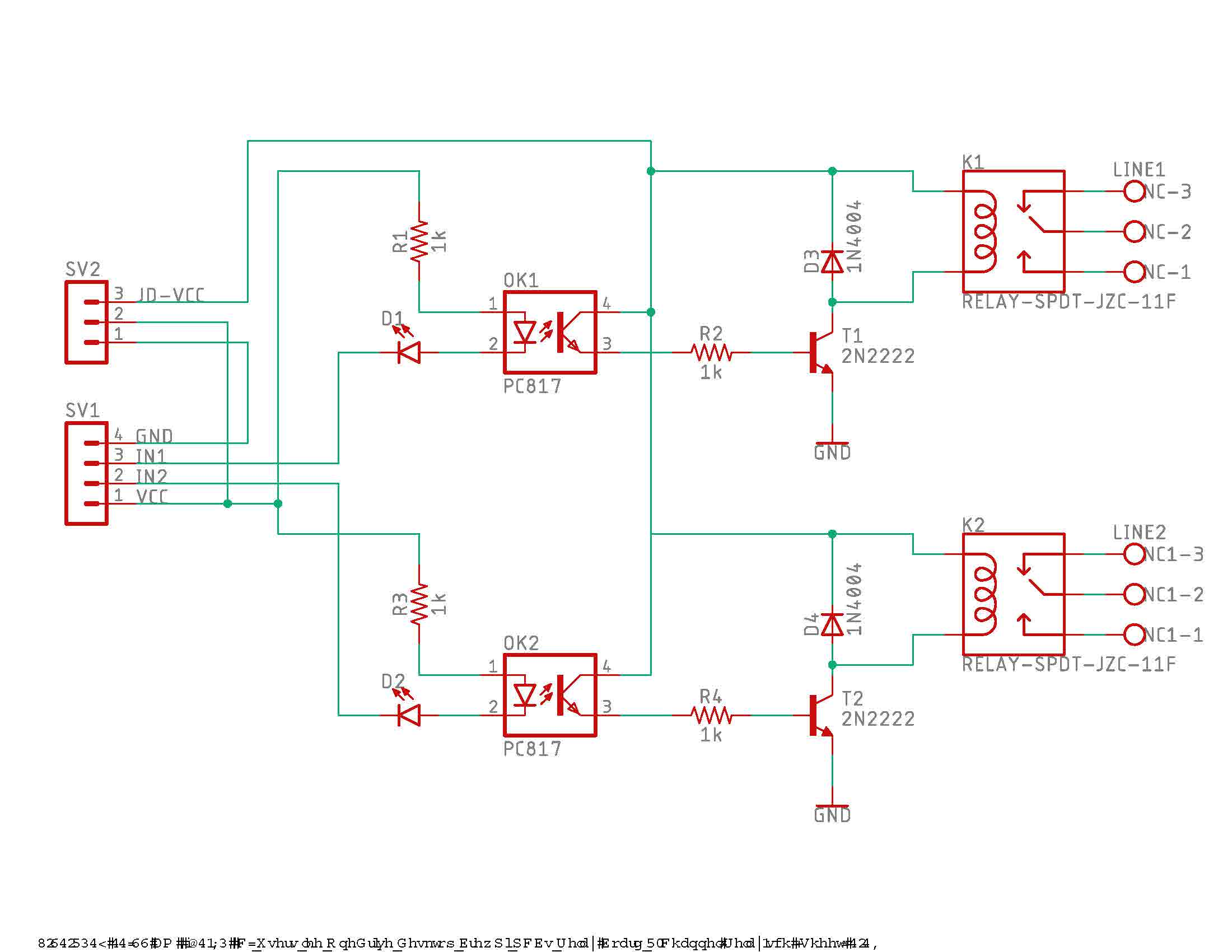

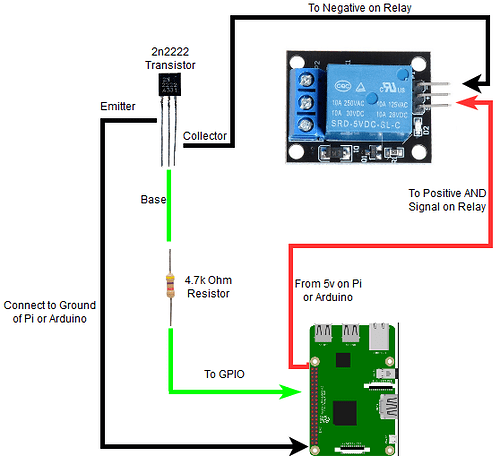

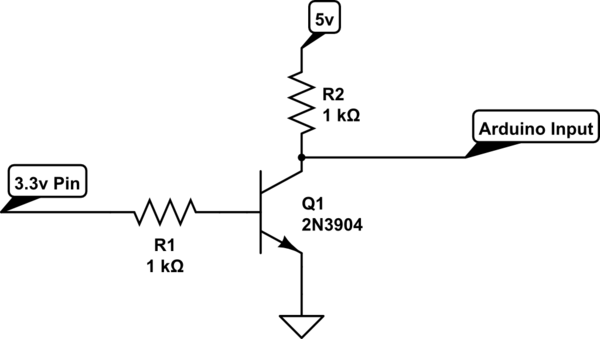

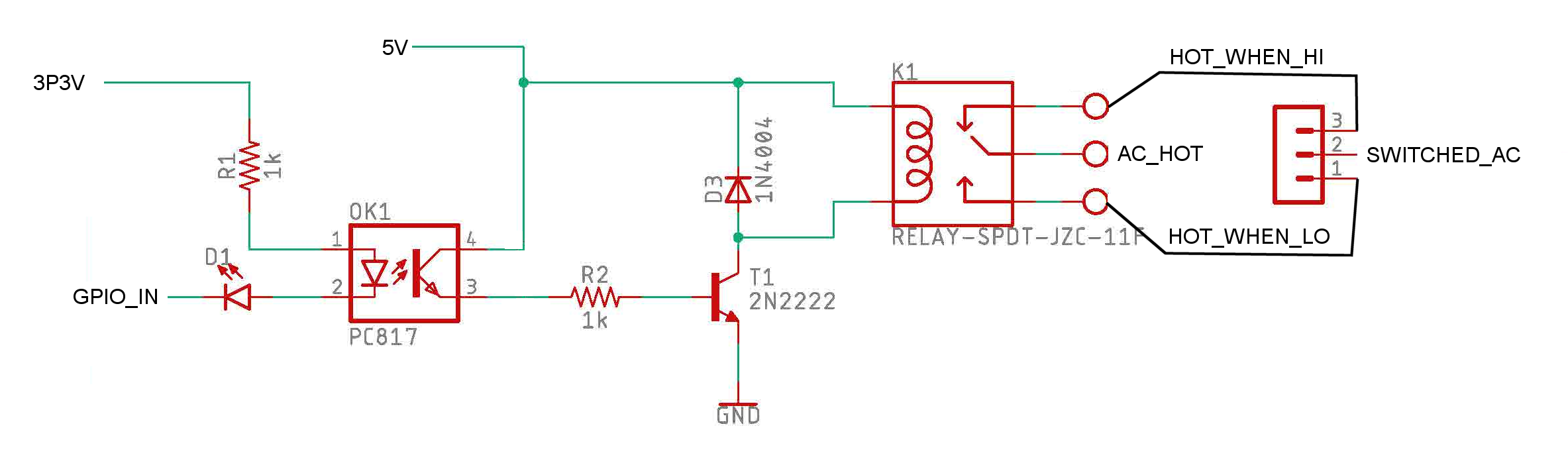

I gave up on the ESP8266 controller (Lolin D1 mini V4.0) given the ver 4 problemThorrak mentioned. I bought a ESP32-S2 and set it up no problem. Only difference I notice is with pin configuration it does not prompt for heat pin and cooling pin like the esp8266 did. I have a choice of Pin 5, 7or 11 for heat and cool. Does it matter which I use? Here are screen shots of how I have it set up. The heat and cool relays are triggered when I test it, just wondering if maybe I had a bad solder or something since pin setup looked different than the ESP8266. Thanks

Attachments

Last edited: