My own new hopping test is going to be with a dip tube screen and whole hops. I've got a Cascadian Dark and a Rye IPA fermenting, and my plan is to put the screens on the dip tube and dump a bunch of hops directly in the kegs. I know this would mess up my pours with pellets, but I figure whole hops + screen should be okay. I'm assuming the hops will eventually sink to bottom.

re: Stouts and Porters

Yes -- these are my favorite styles -- more so than IPAs -- and I've had great luck with stouts and porters. I've brewed several now -- and probably the one I'm going to brew again soon is Denny's Vanilla Imperial Porter (recipe is everywhere -- just google). I skipped the vanilla -- I figure that might add too much of a "gimmick" flavor and I'd get tired of it after several pints -- but I did add 3oz of Jim Beam bourbon to the final 2.5 gallons. That seemed to be the right amount -- for me, at least. A few that tasted it thought I'd used smoked malt (not bourbon) -- so it was interesting how the bourbon -- just a tiny bit of it -- had a pretty big impact. I've got better bourbons, but I figured it's like a cocktail -- if it's a mixer, there's no reason to use top-shelf.

I just finished watching NB's 'Brewing TV' stout and porter episode, so my plans for next month include more authentic stout and porter recipes (according to the episode and according to:

http://barclayperkins.blogspot.com/)

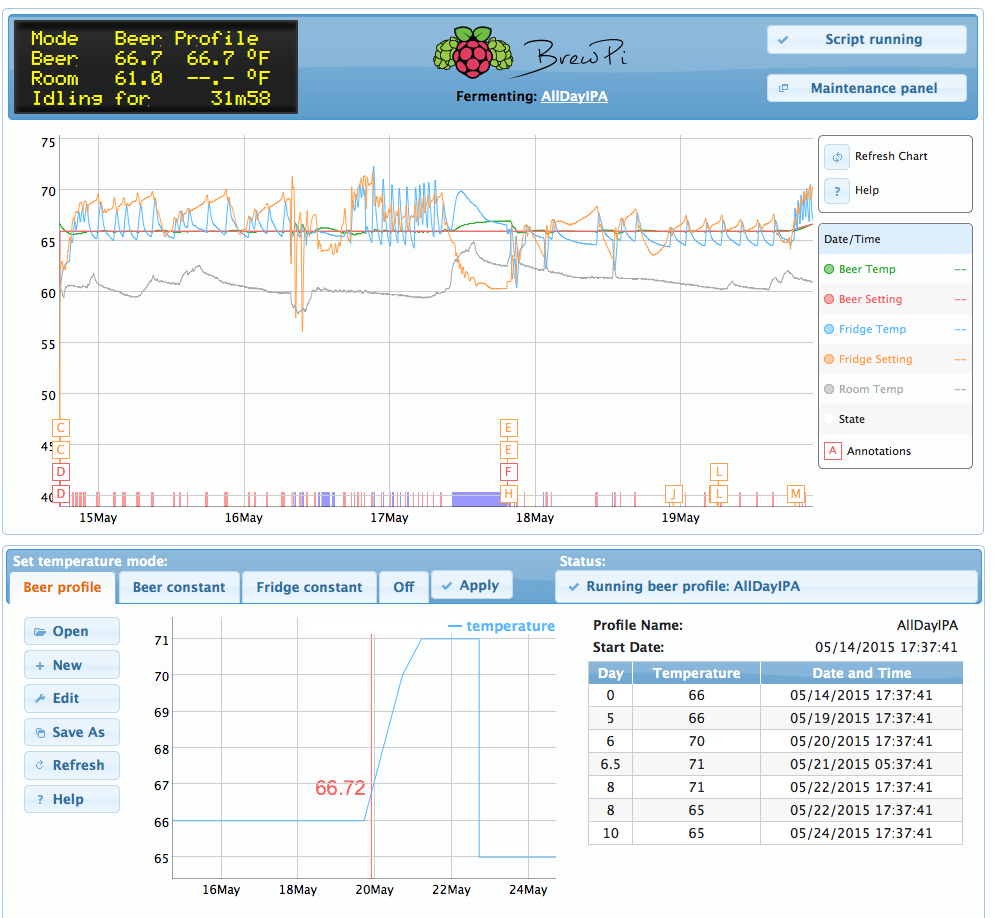

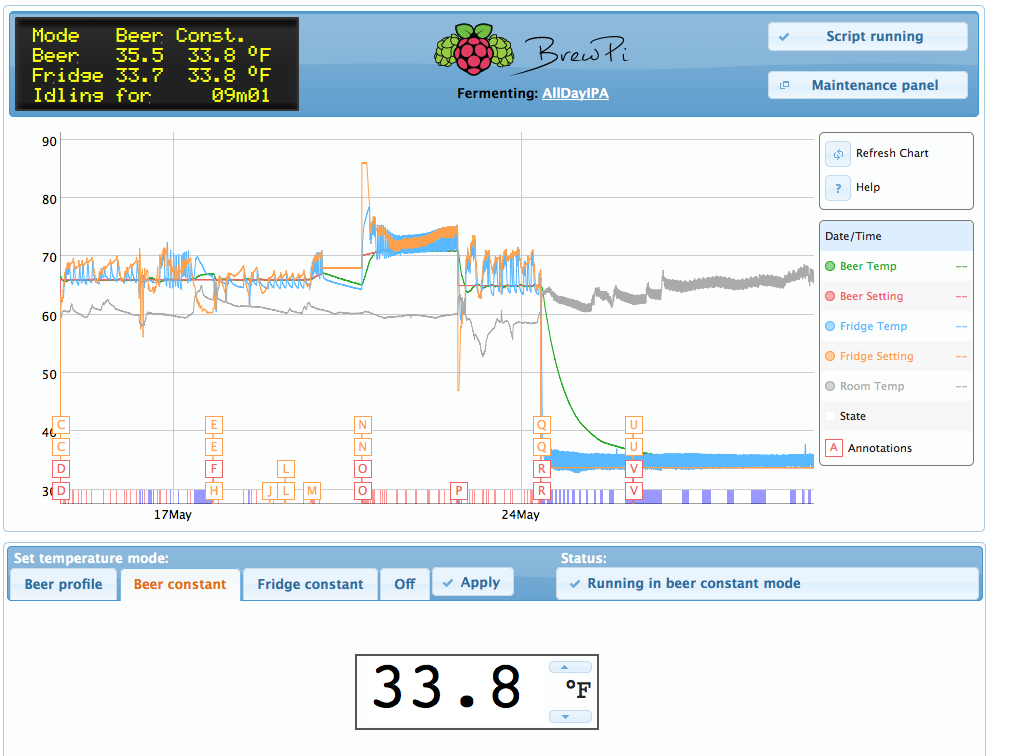

After 20+ batches, my own view is that the beer coming from the Pico is remarkably consistent. No major sanitation issues, no off-flavors. Brew after brew, it's the best (and easiest) beer I've brewed. Granted, this will vary according to user -- and I see that Baja here is approaching the beer from a different angle (I'm very interested in the BrewPi -- but I don't want to overcomplicate what's turning out to be a really enjoyable brewing process) -- but I suspect Baja, too, would agree on consistency. Most errors -- if not every error -- I've had so far are my own fault while the machine -- remarkably -- just chugs away batch after batch.

BTW -- it's interesting to read the other threads here on Pico -- the idea that it's somehow a "cheat" to the process. I suspect the subtext is really that it's an "advantage" to the process of crappy procedural techniques (and bad sanitation). It's like when I hear chefs complain about sous-vide -- that it makes the process too simple or that it robs you of experiencing the "hard work" of cooking. Maybe, but I know a lot of chefs (and engineers and programmers) that find a real elegance in simplicity -- and have come to understand that no one is being "robbed" or "cheated" when the process is stripped down and simplified for consistency. I sous-vide all the time -- and it's far and away the easiest way to get consistent and delicious food -- especially with something like steak. Why overshoot medium rare when you know all a steak needs is 134F for 90 minutes and a good sear? That's it.

Same with Pico. Once you move beyond the "hey, look, I'm making beer!" stage -- you realize, okay, what I really want to do is to make *consistent* beer. To me, that's the real elegance of homebrewing. And that's what the Pico does.