rebel_scum

Well-Known Member

- Joined

- Apr 12, 2014

- Messages

- 63

- Reaction score

- 11

Started a build for a 6 corny kegerator using a 4.9 cu ft fridge I got on the cheap.

I considered doing a keezer, as I am concerned about it being able to hold temp at 40 ish but I had pretty good luck with a similar build for my fermentation chamber which is about 60% larger with a smaller (4.1 cu ft) fridge, so I figured I would give it a shot.

Here is my progress so far- any advice or questions are always welcome:

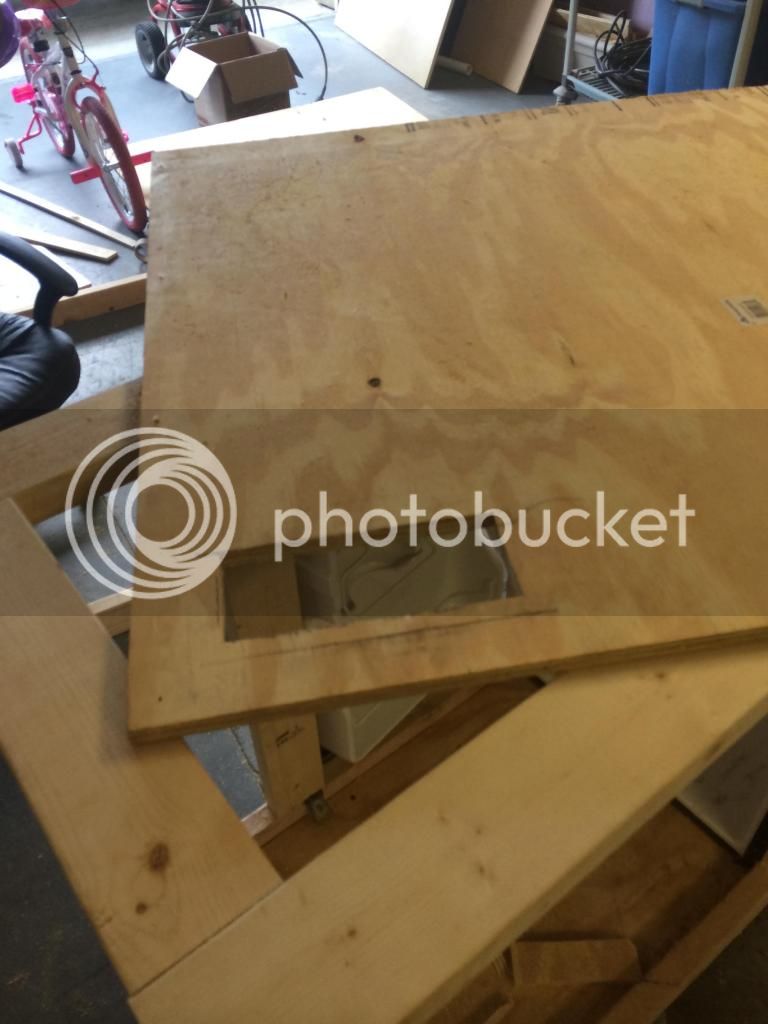

First thing was framing the bottom to hold the fridge, a 20# co2 tank, and 6 5 gallon pin lock corny kegs:

The co2 tank fits nicely directly inside the actual fridge, and 6 kegs will fit with plenty of room to spare.

I built the sides next, I made pocket holes with a kreg jig in case I need to pull the fridge out later down the road.

Built the top frame and routed out the door hinges, I screwed some galvanized strip around the door opening to utilize the gasket on the original door:

Inside view:

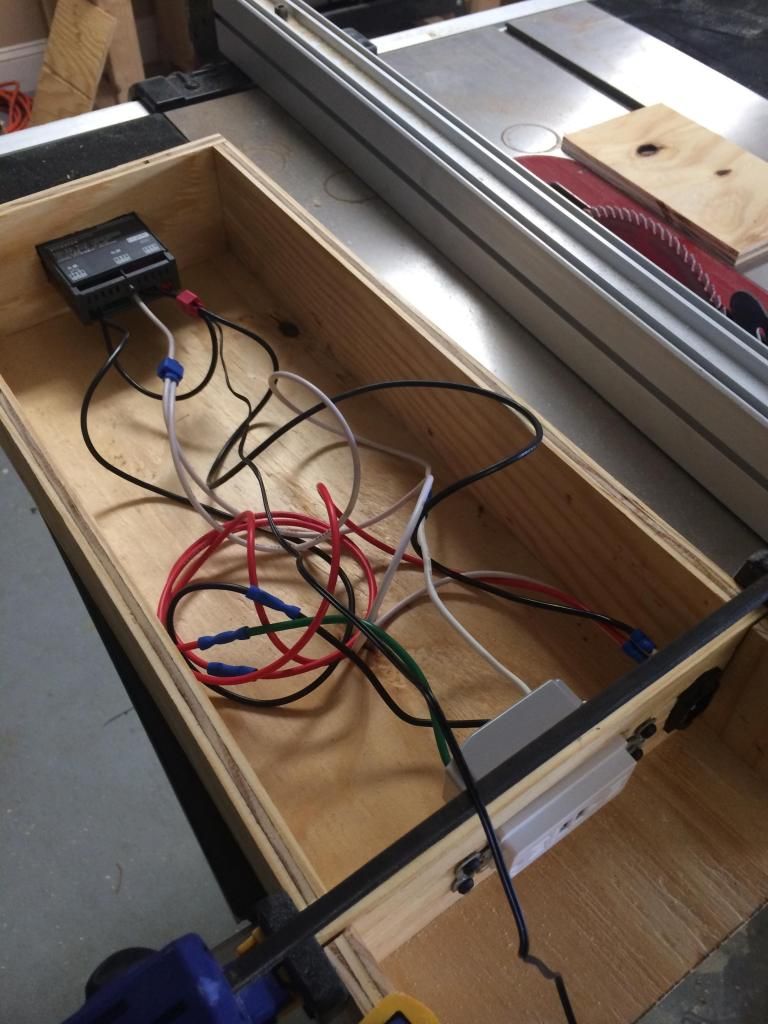

Building a box to house the controller- I am going to try to get it flush mounted on the right hand side of the front part but I am still trying to figure out how:

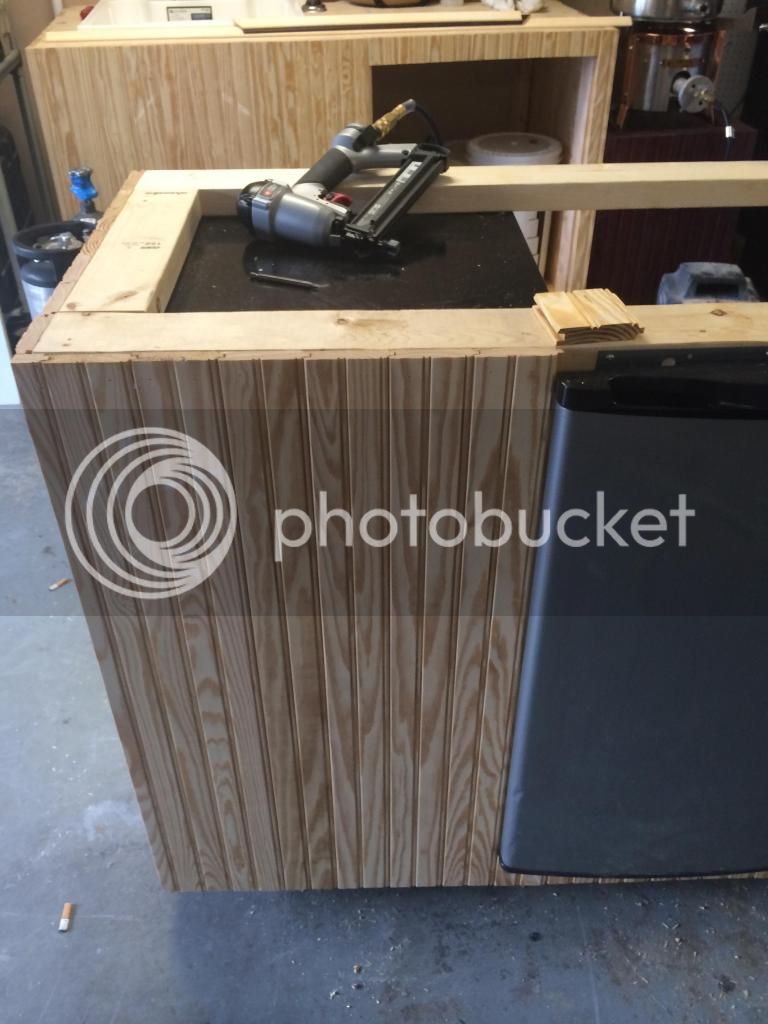

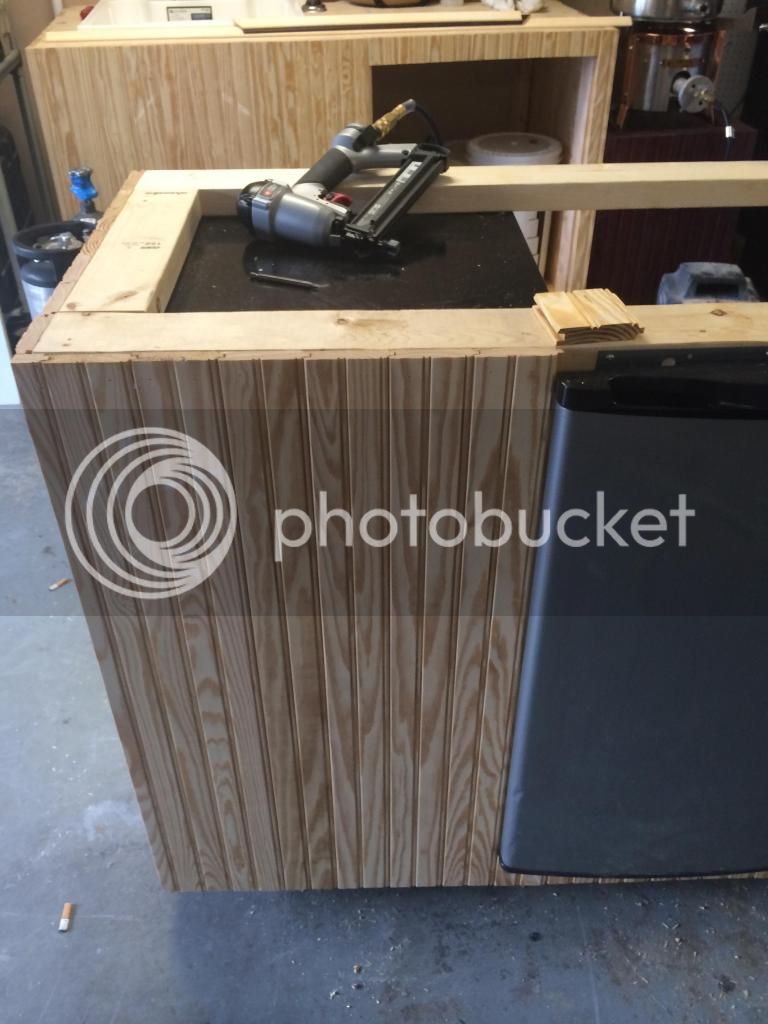

Nailed the trim to the left side and the front, the STC will be mounted on the right side once it is wired up:

That's it for now- Ill keep updating as I go.

Thanks!

Jeff

I considered doing a keezer, as I am concerned about it being able to hold temp at 40 ish but I had pretty good luck with a similar build for my fermentation chamber which is about 60% larger with a smaller (4.1 cu ft) fridge, so I figured I would give it a shot.

Here is my progress so far- any advice or questions are always welcome:

First thing was framing the bottom to hold the fridge, a 20# co2 tank, and 6 5 gallon pin lock corny kegs:

The co2 tank fits nicely directly inside the actual fridge, and 6 kegs will fit with plenty of room to spare.

I built the sides next, I made pocket holes with a kreg jig in case I need to pull the fridge out later down the road.

Built the top frame and routed out the door hinges, I screwed some galvanized strip around the door opening to utilize the gasket on the original door:

Inside view:

Building a box to house the controller- I am going to try to get it flush mounted on the right hand side of the front part but I am still trying to figure out how:

Nailed the trim to the left side and the front, the STC will be mounted on the right side once it is wired up:

That's it for now- Ill keep updating as I go.

Thanks!

Jeff