Does Würth have outlets in Finland?

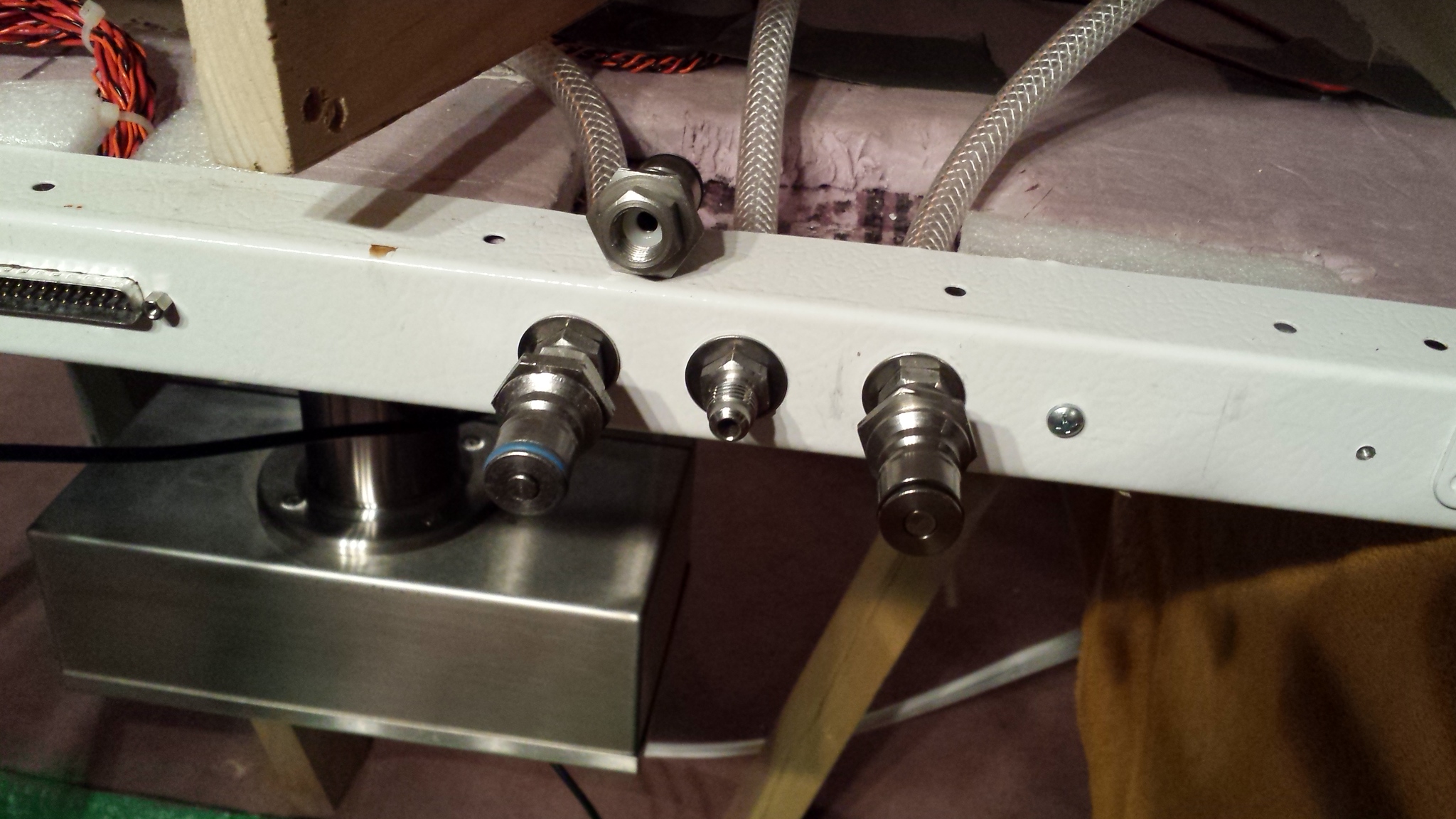

That big bulkhead will work great if you're going straight down though the lid. Otoh, if you are going through the back edge of your freezer lid, you might want to go with "panel mount" MFL bulkheads, like this:

View attachment 848098

On my 1st and 2nd keezers I used a few of these to bring two pressures of CO2 and a beer gas line inside through the back edge of their lids.

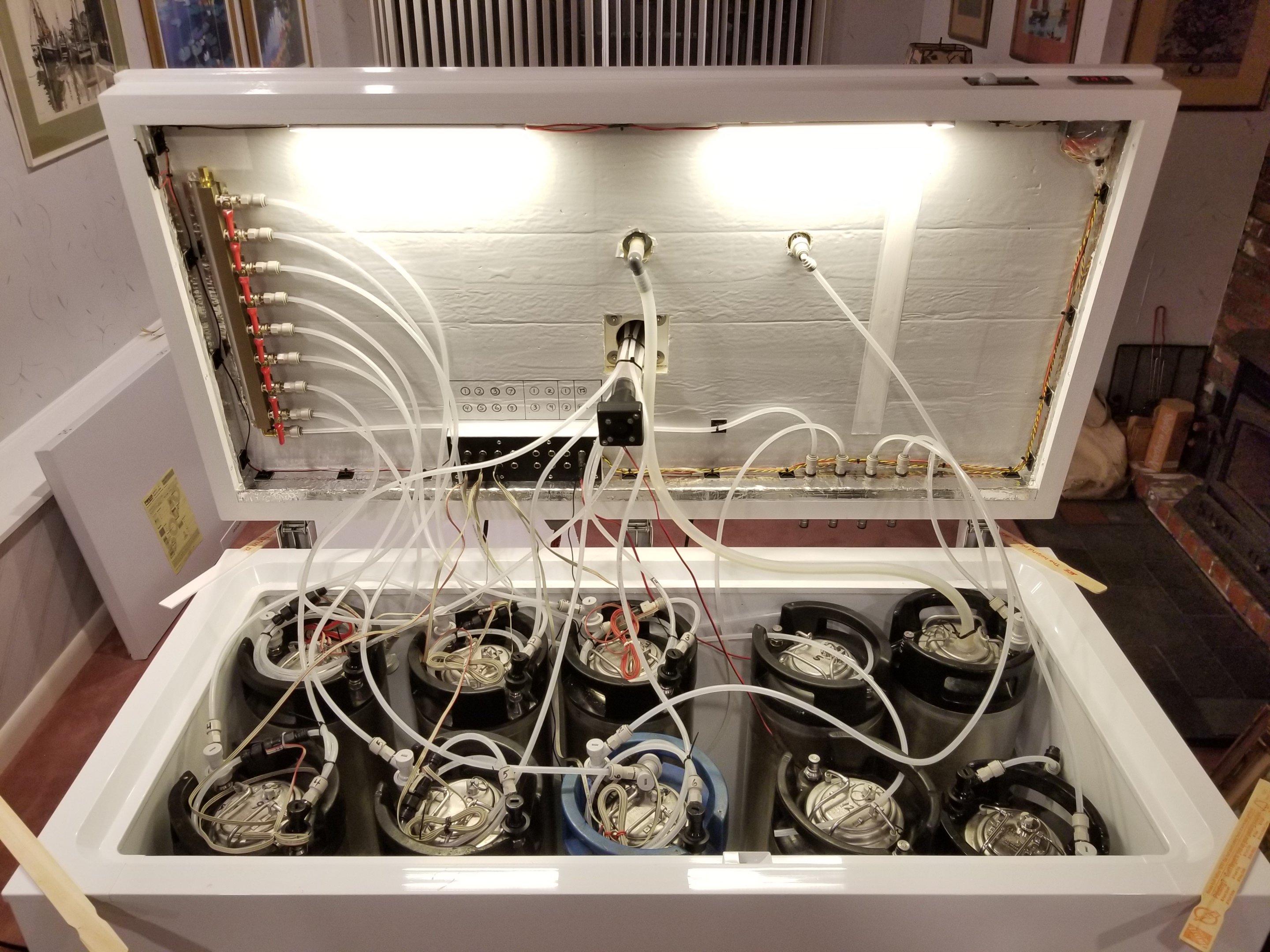

View attachment 848100 View attachment 848101

btw, the oem lid on the freezer I used for my third and current keezer in 2018 came totally filled via "foam-in-place" (signified by huge yellow "Cyclopentane" sticker) which would have required Jobian patience at the minimum to deal with in any similar manner. So I built a custom lid and gave the oem lid back to the retailer. If you're lucky you won't run into that - although going straight through probably won't actually be much of a challenge

Cheers!