- Joined

- Nov 19, 2017

- Messages

- 250

- Reaction score

- 93

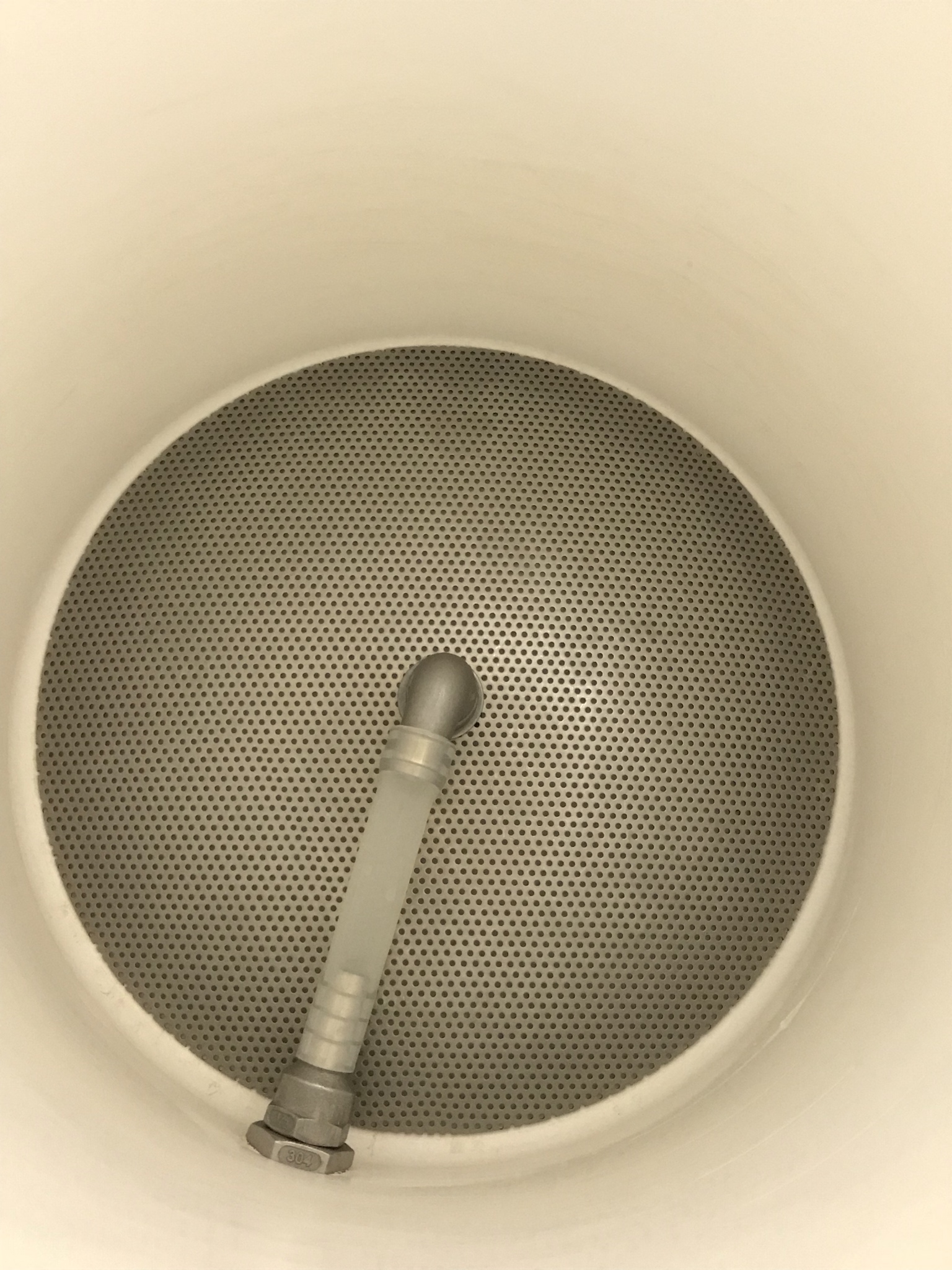

I have a typical dome false bottom that completely covers the bottom of my cooler with all 1/2" hardware and tubing. I can't imagine a better flowing solution given my vessel. I'm tempted to try a more coarse crush though to see what my efficiencies look like.Agree with Blazinlow.

I run full bore and never stir the mash. Crush at 05.

Not sure if this pertains to the OP, but one of the often missed items in troubleshooting this problem is your false bottom.

When I first built my system I had a POS bottom that stuck the mash and actually went from convex to concave from the pressure.

Getting a quality false bottom that covered the entire floor surface of my mash tun solved the problem.

What mash efficiency are you getting at .05? That's pretty coarse.