Top picture looks like a arc mark where it was hit with the TIG torch by accident and not brushed clean. If you are looking for a new kettle let me price one for you. I use kegs if you are interested PM me I can build anything you can imagine.Well, gang, at this point I have to say I'm sorry, but I have given up on Chapman products.

This past Monday I received my replacement kettle for the one that had the rust issues (see above), and after doing a water test in this new one, it actually has worse rust and defects than the other one.

Here are some pictures.

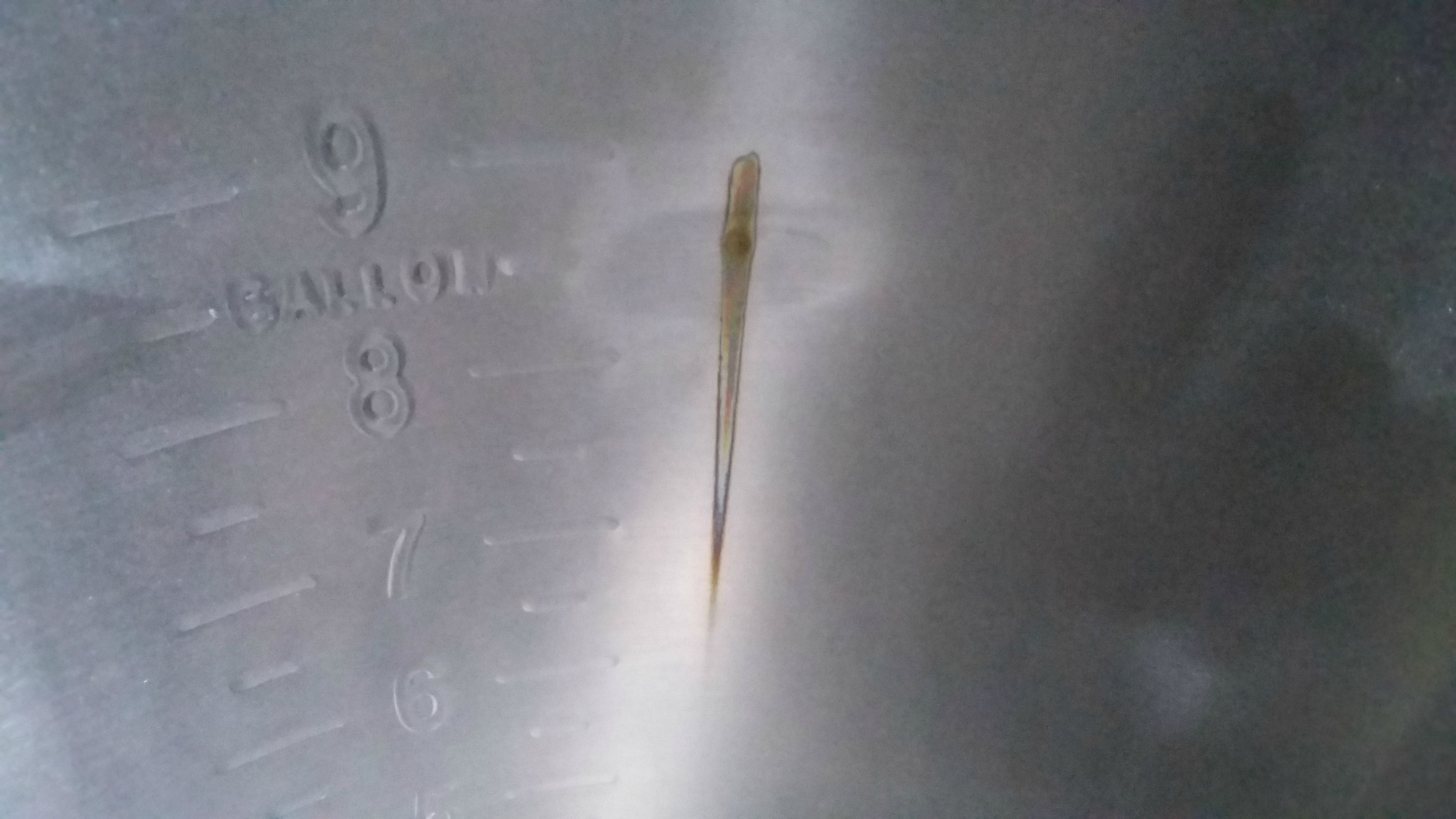

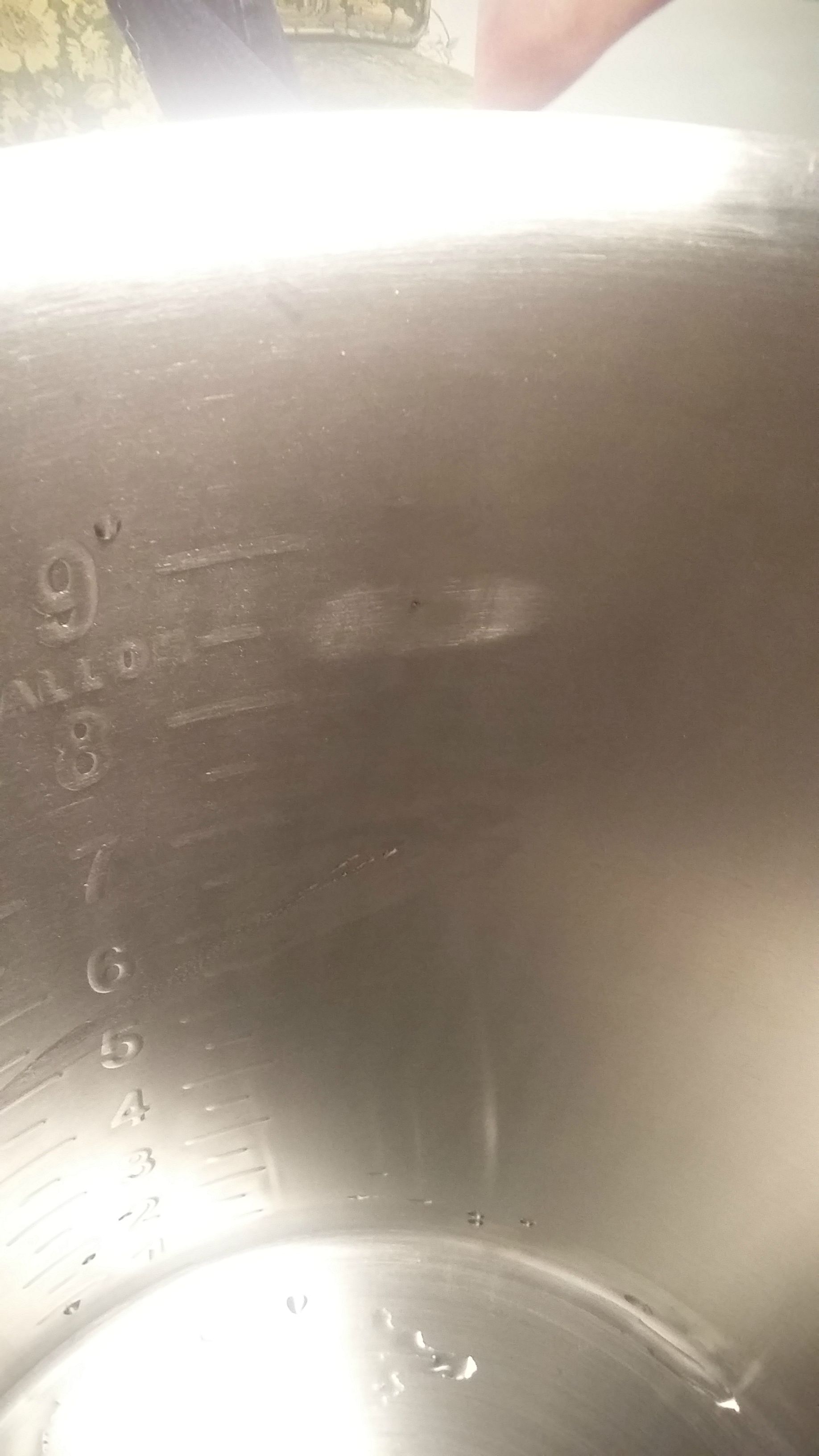

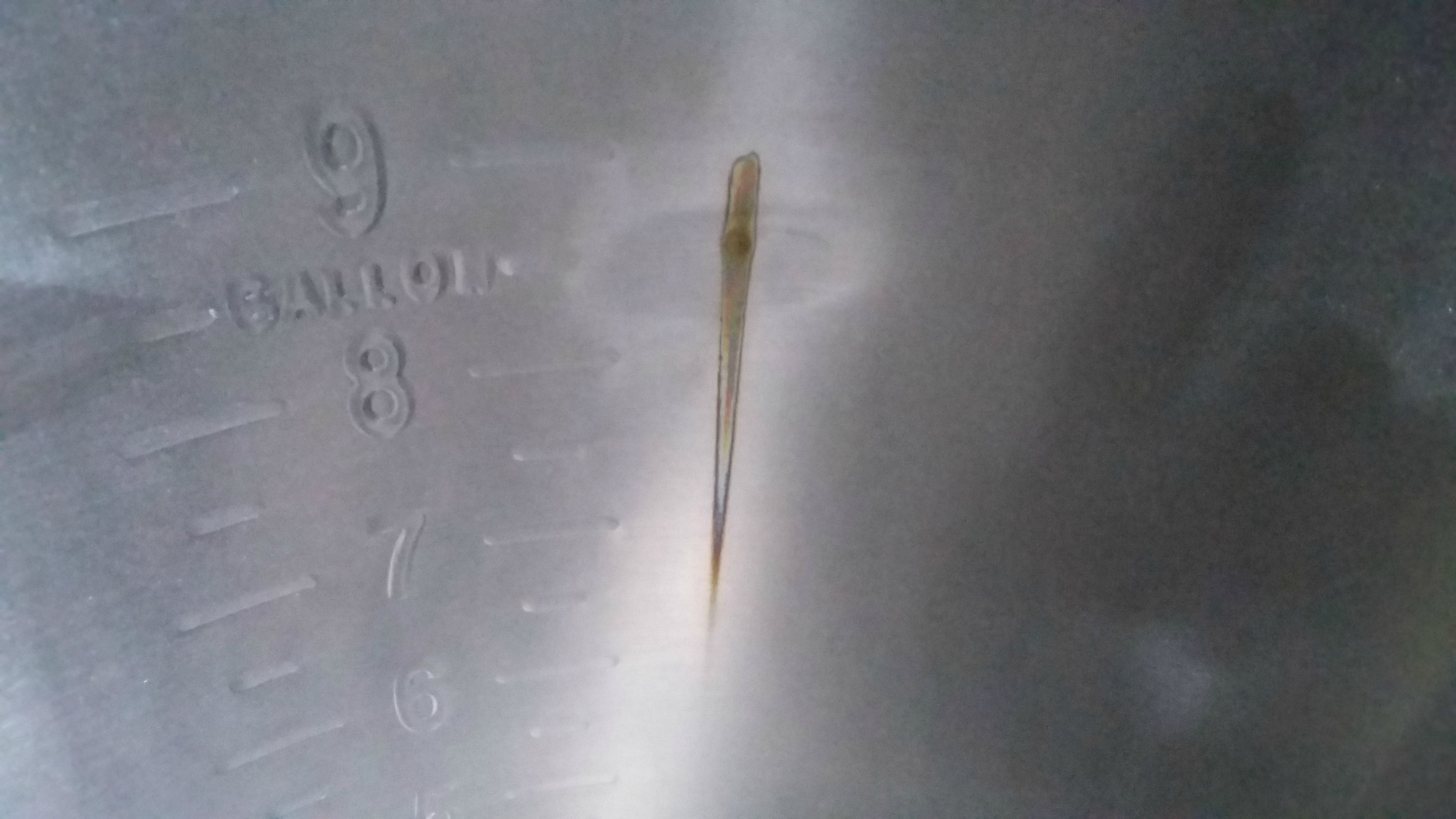

This is the inside of the kettle, back, where the handle is welded on:

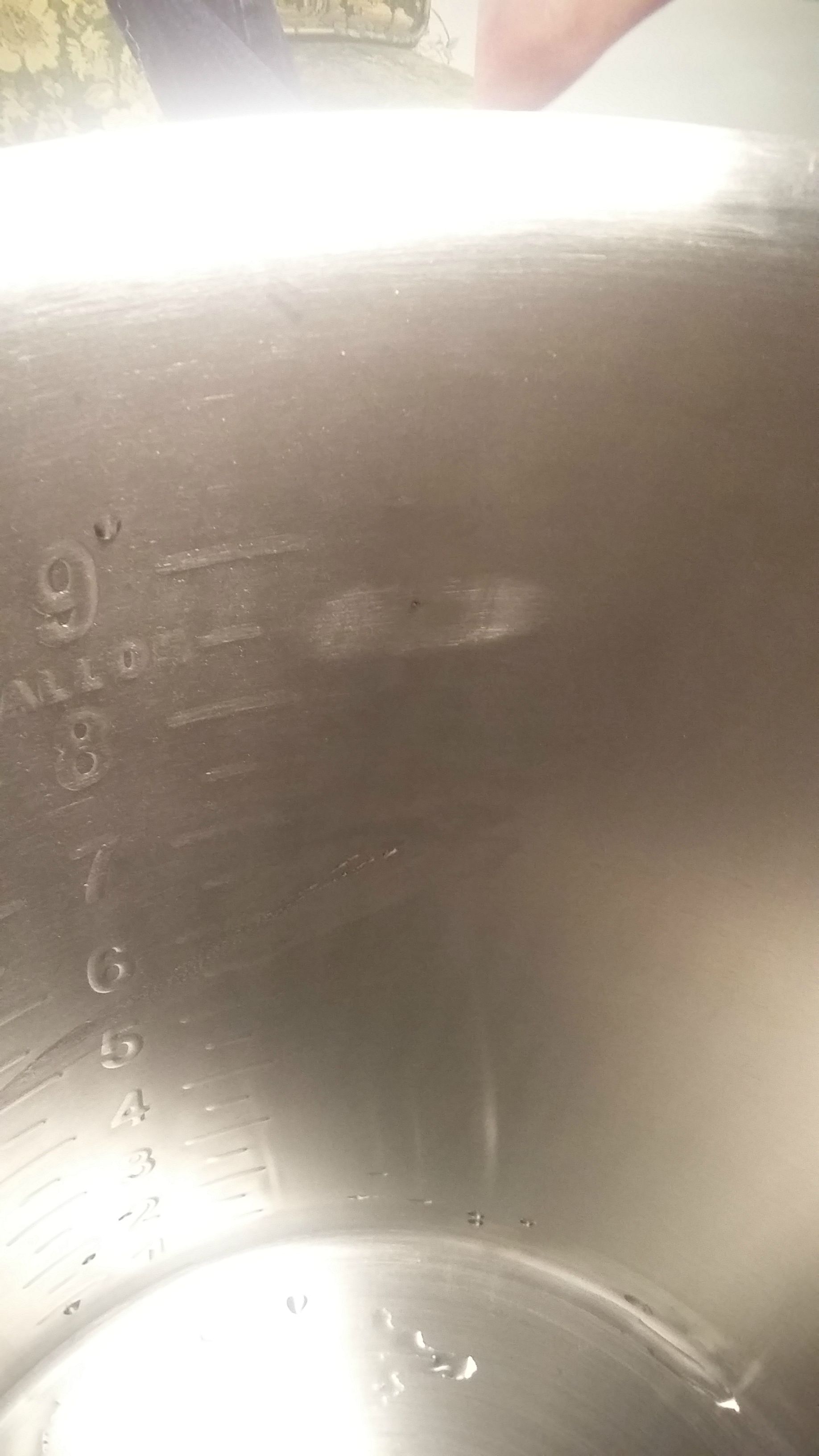

Sorry for the blurry image, but daylight was getting short. This is three large rust spots near the bottom rear of the kettle:

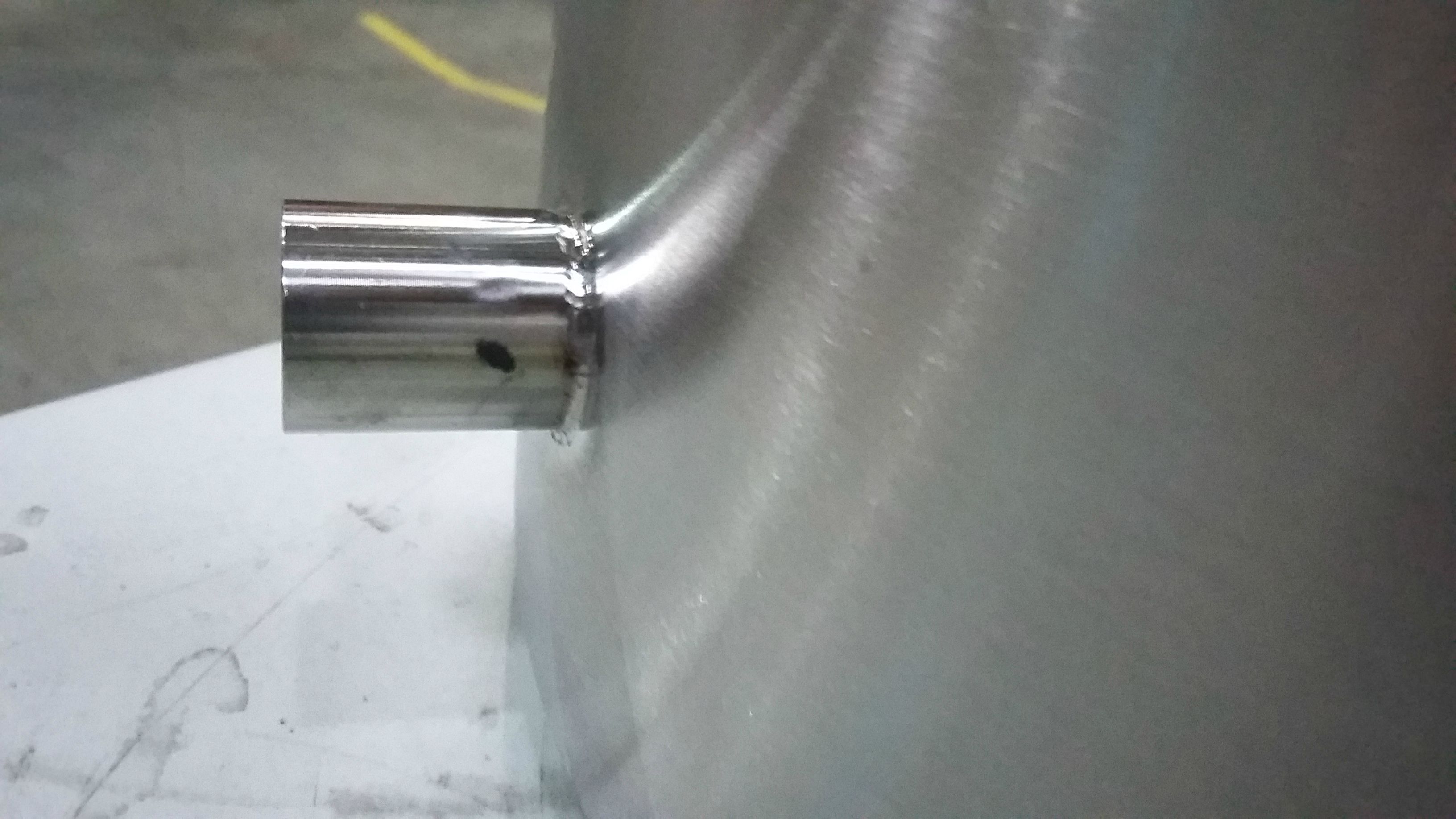

This is not rust, but another pockmark on the inside front of the kettle where the handle is welded on:

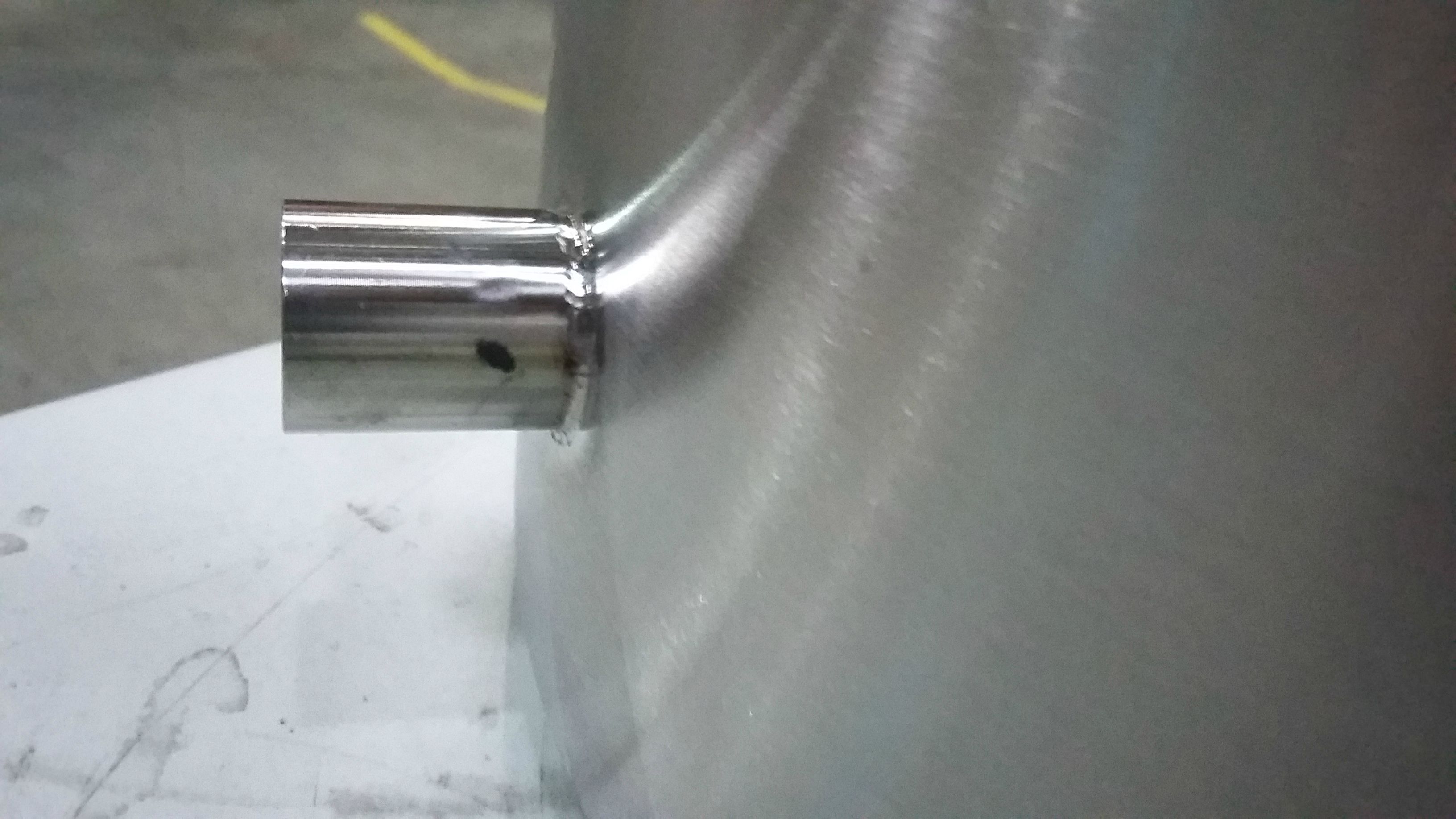

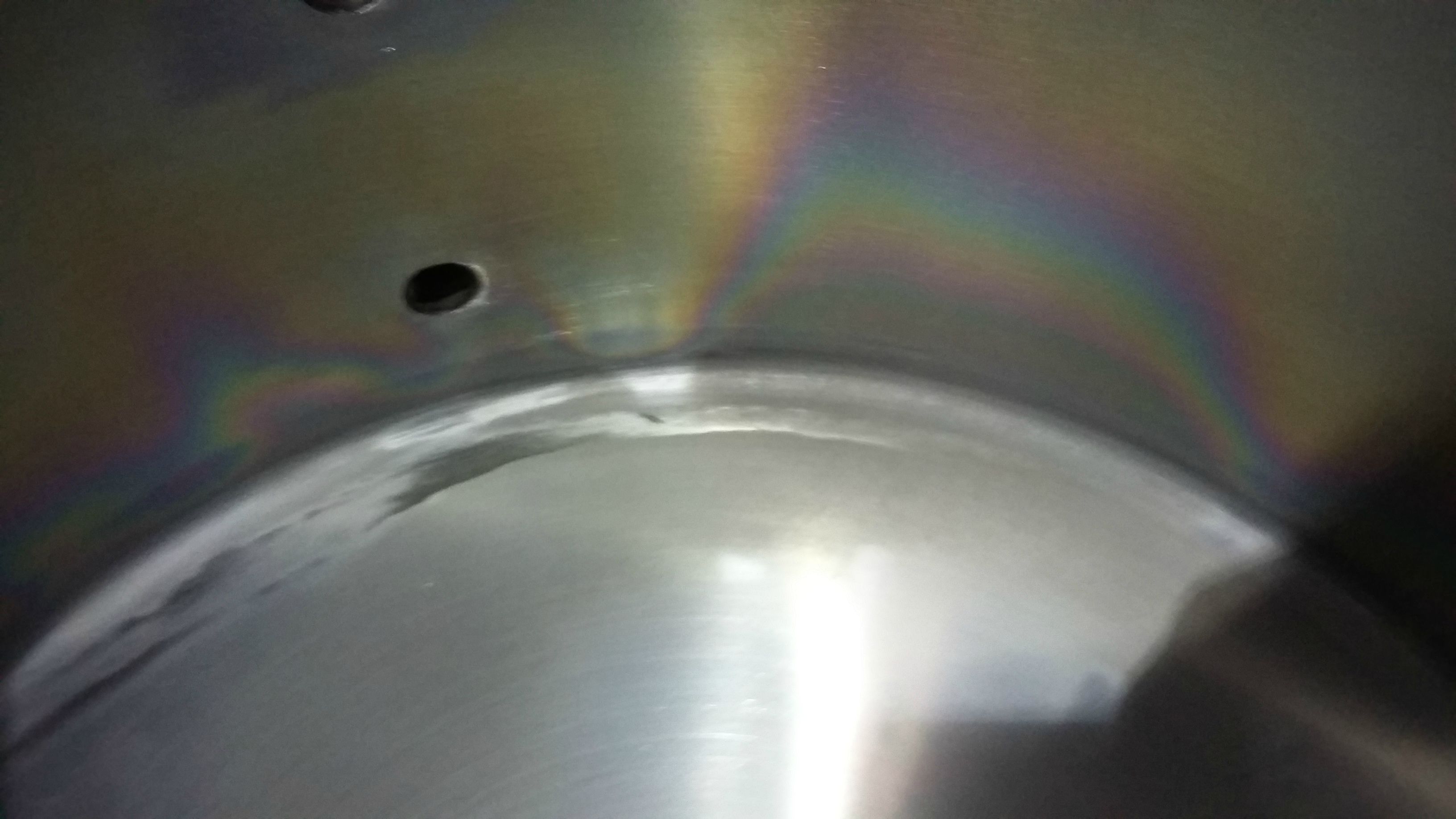

Both of the welded on couplings have these types of strange marks, and this weld is pretty discolored (called this out to Steve prior to starting the water test):

I am also having serious problems with the coupling for the ball valve. Despite my best efforts last night I could not get it to seal (and let me tell you, I torqued the hell out of it), and leaving it over night it had lost 1/2 gallon of water. I also had a hell of a time getting anything to screw in to the inside portion of the coupling. Anything I tried would go about a 1/4 turn, get all cockeyed, and then lockup. Just hand tightening a NPT nipple got it stuck so bad I had to use channel locks to unstick it. I tried two different street 90s, and after hitting one with a hammer a couple of times I got it to thread in, but again it would only go about 1/4 turn before locking up. Luckily that 1/4 turn just happened to be the right position so I lucked out there.

When I initially contacted Steve about the leaking he suggested I try it again using more Teflon tape. That's when I went out to drain the kettle, and found the defects inside. I went ahead and wrapped a mile of Teflon tape around it, but again, within about 30 minutes it started leaking again.

I've reached back out to Steve and requested a refund. Again, I've got nothing but positive remarks to say about his customer service, but his products are definitely lacking in quality. As I told him, even at the Kickstarter prices, a rusty kettle is pretty worthless.

Again, just to be perfectly clear, the only thing I've done with this new kettle was let water sit in it for about 24 hours.

I'm keeping the Thermobarrel as I've already modified it, and I sold off the fermenter as soon as it arrived, so now I'm in the market for a new kettle.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kickstarter for SS Mash Tun, Kettle and Fermenter

- Thread starter rockernino

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Top picture looks like a arc mark where it was hit with the TIG torch by accident and not brushed clean. If you are looking for a new kettle let me price one for you. I use kegs if you are interested PM me I can build anything you can imagine.

Thanks, I appreciate it, but I've already purchased another kettle. I decided to go with a Blichman G2.

ingchr1

Well-Known Member

Just wanted to pass along something I found with the bulkheads on the ThermoBarrel. I pulled the bulkheads for assembly and noticed one of them to have a good amount of green and brown rust/corrosion on the inside (3/8" portion of the bulkhead only). I contacted Chapman and they did send me out another one, but I noticed that one also had a couple of brown spots in it as well. I've contacted them again.

I don't think I would have noticed it had I not pulled them apart. I did put a hard drive magnet up to them and it does not stick, if anything can be concluded from that. I also had another one in and out of water for several days and it did not discolor.

I think I may try some bar keepers friend on them.

Hard to get a good picture but here's the original one, after cleaning:

I don't think I would have noticed it had I not pulled them apart. I did put a hard drive magnet up to them and it does not stick, if anything can be concluded from that. I also had another one in and out of water for several days and it did not discolor.

I think I may try some bar keepers friend on them.

Hard to get a good picture but here's the original one, after cleaning:

Just wanted to pass along something I found with the bulkheads on the ThermoBarrel. I pulled the bulkheads for assembly and noticed one of them to have a good amount of green and brown rust/corrosion on the inside. I contacted Chapman and they did send me out another one, but I noticed that one also had a couple of brown spots in it as well. I've contacted them again.

I don't think I would have noticed it had I not pulled them apart. I did put a hard drive magnet up to them and it does not stick, if anything can be concluded from that. I also had another one in and out of water for several days and it did not discolor.

I think I may try some bar keepers friend on them.

Hard to get a good picture but here's the original one, after cleaning:

View attachment 306683

Oh no, not the Thermobarrels now too! Hard to tell from your picture exactly, but are you finding the rust/corrosion on the...

Custom 1/2" > 3/8" reducing bulkheads that are mounted inside the Thermobarrel?

NPT nipple?

The ball valve itself?

ingchr1

Well-Known Member

On the inside of the 3/8" portion of the bulkhead.

On the inside of the 3/8" portion of the bulkhead.

Got it. Thanks for posting the pictures. Looks like one more thing to watch out for with this gear. Unfortunately that seems very difficult to spot unless you remove the bulkhead, but I'll try to keep an eye out on mine.

Doing my final end-to-end test of my new single tier, single pump system this Saturday (which uses a 10 gallon Chapman Thermobarrel), and then hopefully brewing on Sunday. I'll report back if I notice any issues.

Frostbrewer

Well-Known Member

How about some positive press for this stuff? Lol. Poor steve has been put through the wringer lately

I have two fermentation buckets. My first one didn't clamp properly so steve replaced it. Awesome!

I brewed an oktoberfest in the first bucket while the other was in the mail. Worked great! No rust issues and cleanup after the transfer to the keg was super easy. Really happy with my buckets.

I hope there are other positive reviews out there

I have two fermentation buckets. My first one didn't clamp properly so steve replaced it. Awesome!

I brewed an oktoberfest in the first bucket while the other was in the mail. Worked great! No rust issues and cleanup after the transfer to the keg was super easy. Really happy with my buckets.

I hope there are other positive reviews out there

ingchr1

Well-Known Member

Exactly, don't think I would have noticed it had I not removed them.Unfortunately that seems very difficult to spot unless you remove the bulkhead

Also, all of them needed a good cleaning with a brush in that 3/8" section.

val214

Well-Known Member

Sad, to hear you guys are having problems with your gear. I have modified and brewed 4 batches with my thermobarrel with no issues.

ingchr1

Well-Known Member

I'm not too bothered by it, it will get resolved. I'm thinking some bar keepers friend to passivate them. I have no problem taking care of that myself, and if it fixes them then that will be that. My posting up is more so others will inspect theirs, since it may not be readily apparent with them installed.Sad, to hear you guys are having problems with your gear.

Overall I'm still happy with my purchase, and can't wait to brew with it.

How about some positive press for this stuff? Lol. Poor steve has been put through the wringer lately

This was the first negative stuff I'd seen on the Thermobarrel, which all-in-all seems like a solid piece of kit and was a steal at the Kickstarter price.

While I've had problems with my kettles, Steve has been great through everything, and I continue to be impressed with his customer service and how he's worked through the various issues that have arisen thus far. Others have commented on that as well, so hats off to him there.

I'm glad when people post info like that on the bulkheads, as everyone is informed and can watch out for it. Maybe won't be a a problem for everyone, but for those that do run into it, and catch it early, it seems like an easy fix.

Still happy that I got in on the Kickstarter, even if I only wound up keeping the Thermobarrel, and I'm looking forward to seeing what Steve comes up with in the future!

ChapmanEquipment

Active Member

As I've said before, Chapman Brewing Equipment is a no BS company. And to keep true to my word. Here is a comprehensive list of all the problems we have encountered so far:

Here are explanations of our reactions to those problems. If I have overlooked anything, please let me know.

-

Delays in shipping (Won't be an issue in the future)

Since we encountered a lot of these problems in the middle of shipping, we decided to halt shipping until they were resolved. Some people received shipping notifications but had to wait weeks for their gear. We should have made the delays clear to each individual person, but it is hard to coordinate communications when we are working as hard as we can to get all the problems solved.

In the end, a lot was delivered early. Most of the issues have been resolved. And there were less than 5 percent Kickstarter supporters who did not receive all of their equipment by September 30th.

Fermenter volume markings off UNRESOLVED

I've written about this before here: https://www.homebrewtalk.com/showpost.php?p=6936149&postcount=119

In short, the problem was too difficult to fix. And because no equipment has 100% accurate volume markings, we accepted the flaw. Many companies would not announce this publicly and would wait for you to find out on your own. In good faith, we are informing everyone to at least tell you how much you need to adjust for.

No logos RESOLVED

This was largely a problem between us and the manufacturer. We have worked something out with them.

Dip tube not sealing properly RESOLVED

We recommend a new configuration for attaching the dip-tube and sent out o-rings to everyone for those that needed them.

Straight nipple sent out instead of tapered one/fermenter bulkhead not sealing RESOLVED

This arose because our fittings supplier (separate from our main supplier) sent us the wrong parts labeled as the correct parts. We didn't catch this right away. We found a local supplier for fittings and will be using them in the future. They are a bit more expensive but it's worth it.

Also, we reconfigured the fermenter bulkhead and sent out hex nuts and o-rings along with the nipple to ensure ease of assembly.

Some kettles were not passivated IN PROGRESS

We are still trying to determine to what extent this has become an issue. At first it looked like an isolated incident, but now its looking like it might be more than just a couple kettles.

The solution is to repassivate the kettles. When we figure out the extent of the problem, we will decide whether to passivate the kettles ourselves or find an easy way for end-users to passivate them.

ThermoBarrel fitting(s) rusted IN PROGRESS

This was brought up by ingchr1, and I've been communicating with him on possible causes/solutions. So far we haven't heard from anyone else. We have not had the time to check each individual ThermoBarrel bulkhead and we plan on doing this over the next few weeks.

Fermenter clamps not sealing properly RESOLVED

This issue has arisen for two people so far. These lids didn't seal all the way because the clamps weren't bent down far enough. One supporter figured out how to bend them down on their own. We exchanged the other one at no cost to the supporter. In the future, this is something we will have to double check before we send it out, but it's a problem we can fix.

Insufficient packaging for the ThermoBarrel RESOLVED

The few supporters who had dents in their ThermoBarrels from shipping were offered replacements. Most decided that free gear or store credit would be enough to remedy the cosmetic damage to the mash tun.

We have reconfigured the packaging for the ThermoBarrel and don't expect any more serious issues from shipping. Furthermore, we are working on custom designs for all packaging.

-

Of the nine issues listed above one remains unresolved, and two are in progress. It's still not clear how major those two issues are. All the other issues have been remedied in one way or another. Even with no hassle refunds, only one KS backer who saw the equipment in person asked for a refund (drgonzo2k2).

We are planning on sending out a survey to all the Kickstarter supporters to get more feedback about the equipment at the end of the month. Hopefully most people will have had a chance to use their equipment by then. Even though there have been a lot of issues brought up in this thread, I'm expecting the majority of the feedback on the survey to be positive. We are planning to make the results public, and I will post them here when they are.

- Delays in shipping

- Fermenter volume markings off

- No logos

- Dip tube not sealing properly

- Straight threaded nipple sent out instead of tapered one/fermenter bulkhead not sealing

- Kettle not passivated

- ThermoBarrel bulkhead rusted

- Fermenter clamps not sealing properly

- Insufficient packaging for the ThermoBarrel

Here are explanations of our reactions to those problems. If I have overlooked anything, please let me know.

-

Delays in shipping (Won't be an issue in the future)

Since we encountered a lot of these problems in the middle of shipping, we decided to halt shipping until they were resolved. Some people received shipping notifications but had to wait weeks for their gear. We should have made the delays clear to each individual person, but it is hard to coordinate communications when we are working as hard as we can to get all the problems solved.

In the end, a lot was delivered early. Most of the issues have been resolved. And there were less than 5 percent Kickstarter supporters who did not receive all of their equipment by September 30th.

Fermenter volume markings off UNRESOLVED

I've written about this before here: https://www.homebrewtalk.com/showpost.php?p=6936149&postcount=119

In short, the problem was too difficult to fix. And because no equipment has 100% accurate volume markings, we accepted the flaw. Many companies would not announce this publicly and would wait for you to find out on your own. In good faith, we are informing everyone to at least tell you how much you need to adjust for.

No logos RESOLVED

This was largely a problem between us and the manufacturer. We have worked something out with them.

Dip tube not sealing properly RESOLVED

We recommend a new configuration for attaching the dip-tube and sent out o-rings to everyone for those that needed them.

Straight nipple sent out instead of tapered one/fermenter bulkhead not sealing RESOLVED

This arose because our fittings supplier (separate from our main supplier) sent us the wrong parts labeled as the correct parts. We didn't catch this right away. We found a local supplier for fittings and will be using them in the future. They are a bit more expensive but it's worth it.

Also, we reconfigured the fermenter bulkhead and sent out hex nuts and o-rings along with the nipple to ensure ease of assembly.

Some kettles were not passivated IN PROGRESS

We are still trying to determine to what extent this has become an issue. At first it looked like an isolated incident, but now its looking like it might be more than just a couple kettles.

The solution is to repassivate the kettles. When we figure out the extent of the problem, we will decide whether to passivate the kettles ourselves or find an easy way for end-users to passivate them.

ThermoBarrel fitting(s) rusted IN PROGRESS

This was brought up by ingchr1, and I've been communicating with him on possible causes/solutions. So far we haven't heard from anyone else. We have not had the time to check each individual ThermoBarrel bulkhead and we plan on doing this over the next few weeks.

Fermenter clamps not sealing properly RESOLVED

This issue has arisen for two people so far. These lids didn't seal all the way because the clamps weren't bent down far enough. One supporter figured out how to bend them down on their own. We exchanged the other one at no cost to the supporter. In the future, this is something we will have to double check before we send it out, but it's a problem we can fix.

Insufficient packaging for the ThermoBarrel RESOLVED

The few supporters who had dents in their ThermoBarrels from shipping were offered replacements. Most decided that free gear or store credit would be enough to remedy the cosmetic damage to the mash tun.

We have reconfigured the packaging for the ThermoBarrel and don't expect any more serious issues from shipping. Furthermore, we are working on custom designs for all packaging.

-

Of the nine issues listed above one remains unresolved, and two are in progress. It's still not clear how major those two issues are. All the other issues have been remedied in one way or another. Even with no hassle refunds, only one KS backer who saw the equipment in person asked for a refund (drgonzo2k2).

We are planning on sending out a survey to all the Kickstarter supporters to get more feedback about the equipment at the end of the month. Hopefully most people will have had a chance to use their equipment by then. Even though there have been a lot of issues brought up in this thread, I'm expecting the majority of the feedback on the survey to be positive. We are planning to make the results public, and I will post them here when they are.

Has the material had metallurgical testing done in the US? I think I've read these are 201 and not 304, correct? I'd suspect it's less of a passivization issue and more of an issue with chromium and nickel content.

ChapmanEquipment

Active Member

Has the material had metallurgical testing done in the US? I think I've read these are 201 and not 304, correct? I'd suspect it's less of a passivization issue and more of an issue with chromium and nickel content.

If it were due to the type of metal, every piece would have an issue, and the oxidation would cover the piece in a uniform manner. This is happening occasionally and only in specific areas, which clearly indicates an issue with passivation.

Even with no hassle refunds, only one KS backer who saw the equipment in person asked for a refund (drgonzo2k2).

And just to be clear, I only asked for a refund on 1 of the 3 pieces of gear I received, the kettle, due to the issues I've posted about here. I've used the ThermoBarrel twice now in the past few days, and that thing is solid! It only dropped .1 degree over the course of an hour.

If it were due to the type of metal, every piece would have an issue, and the oxidation would cover the piece in a uniform manner. This is happening occasionally and only in specific areas, which clearly indicates an issue with passivation.

My questioned wasn't answered though. Has the material been tested? What is the chromium content? Nickel content?

I would actually come to the opposite conclusion as you. It looks like the rust is mostly occurring around the heat affected zone of the weld areas ie couplers, handles, etc. If the chromium levels in the SS were low to begin with and the welds were too hot and not shielded correctly the chromium could have been blown out during the welding process. That would leave the area with very little corrosion resistance and passivization would do very little.

ChapmanEquipment

Active Member

My questioned wasn't answered though. Has the material been tested? What is the chromium content? Nickel content?

I would actually come to the opposite conclusion as you. It looks like the rust is mostly occurring around the heat affected zone of the weld areas ie couplers, handles, etc. If the chromium levels in the SS were low to begin with and the welds were too hot and not shielded correctly the chromium could have been blown out during the welding process. That would leave the area with very little corrosion resistance and passivization would do very little.

It has not been tested in the US. It's 201 type stainless steel which is 18/4/6 compared to 304 which is 18/8/2 for chromium/nickel/manganese content. Welding will remove the passivated layer regardless of which type of stainless steel it is.

I'm not sure what we would learn from testing it in the US, unless you are suggesting that we didn't receive type 201 stainless steel.

It has not been tested in the US. It's 201 type stainless steel which is 18/4/6 compared to 304 which is 18/8/2 for chromium/nickel/manganese content. Welding will remove the passivated layer regardless of which type of stainless steel it is.

I'm not sure what we would learn from testing it in the US, unless you are suggesting that we didn't receive type 201 stainless steel.

That's what I am suggesting. I would highly suggest having the material tested by a 3rd party. After dealing with China for many years what you request the part be made out of and what it is actually made out of can be 2 different things.

Again SS reacts with oxygen naturally to form an oxide layer so chemical passivization is not always needed. I would look into material type as a solution. Just trying to help

ChapmanEquipment

Active Member

That's what I am suggesting. I would highly suggest having the material tested by a 3rd party. After dealing with China for many years what you request the part be made out of and what it is actually made out of can be 2 different things.

Again SS reacts with oxygen naturally to form an oxide layer so chemical passivization is not always needed. I would look into material type as a solution. Just trying to help

I guess it can't hurt to get testing done just to be sure. I haven't seen anything that would suggest we received a type of stainless steel any different than what we expected. Also, the problems are still pretty rare. (All the issues with discoloration have been posted in this thread.)

But it might be smart to get testing done on those specific pieces. I'll look into a local agent. And if we do go ahead with testing, I think I'll do testing on the same kettle that drgonzo2k2 returned. Also, it might be smart to test the ThermoBarrel bulkhead fitting specifically. I'll keep posting updates in this thread as we progress.

But just as a side note, issues with passivization are fairly common even with type 304 stainless steel. For example, Bru Gear recommends everyone passivate their equipment before first use. This is one reason why I talked to our manufacturer about passivation and confirmed they were passivating the equipment on site. But it's hard to catch the mistakes in passivation before they are sent out, which is what resulted in the issues being posted here it seems.

- Joined

- Dec 5, 2014

- Messages

- 255

- Reaction score

- 53

I believe SS Brewtech recommends people to passivate as well.

ingchr1

Well-Known Member

I wanted to post an update on what I found with the bulkheads. There appears to be two different versions. One is shorter and thinner in the 3/8" portion while the other is taller and thicker. It's the taller/thicker ones (on the right in the attached photos) that I've seen the corrosion on the inside of the 3/8" portion. The replacement Chapman sent me was a taller/thicker one, like my original one posted earlier (post #323). The replacement had a very slight amount of rust in it when it arrived. I treated that one with bar keepers friend, which removed the rust. I placed both types in tap water over night and the taller/thicker one corroded, pretty much on the entire interior surface of the 3/8" portion.

The thinner/shorter ones showed no signs of corrosion. I did treat those with BKF as well, but my earlier test prior to treatment also did not show corrosion.

As Chapman posted, they are currently looking into this.

The thinner/shorter ones showed no signs of corrosion. I did treat those with BKF as well, but my earlier test prior to treatment also did not show corrosion.

As Chapman posted, they are currently looking into this.

As I've said before, Chapman Brewing Equipment is a no BS company. And to keep true to my word. Here is a comprehensive list of all the problems we have encountered so far:

- Delays in shipping

- Fermenter volume markings off

- No logos

- Dip tube not sealing properly

- Straight threaded nipple sent out instead of tapered one/fermenter bulkhead not sealing

- Kettle not passivated

- ThermoBarrel bulkhead rusted

- Fermenter clamps not sealing properly

- Insufficient packaging for the ThermoBarrel

Here are explanations of our reactions to those problems. If I have overlooked anything, please let me know.

-

Delays in shipping (Won't be an issue in the future)

Since we encountered a lot of these problems in the middle of shipping, we decided to halt shipping until they were resolved. Some people received shipping notifications but had to wait weeks for their gear. We should have made the delays clear to each individual person, but it is hard to coordinate communications when we are working as hard as we can to get all the problems solved.

In the end, a lot was delivered early. Most of the issues have been resolved. And there were less than 5 percent Kickstarter supporters who did not receive all of their equipment by September 30th.

Fermenter volume markings off UNRESOLVED

I've written about this before here: https://www.homebrewtalk.com/showpost.php?p=6936149&postcount=119

In short, the problem was too difficult to fix. And because no equipment has 100% accurate volume markings, we accepted the flaw. Many companies would not announce this publicly and would wait for you to find out on your own. In good faith, we are informing everyone to at least tell you how much you need to adjust for.

No logos RESOLVED

This was largely a problem between us and the manufacturer. We have worked something out with them.

Dip tube not sealing properly RESOLVED

We recommend a new configuration for attaching the dip-tube and sent out o-rings to everyone for those that needed them.

Straight nipple sent out instead of tapered one/fermenter bulkhead not sealing RESOLVED

This arose because our fittings supplier (separate from our main supplier) sent us the wrong parts labeled as the correct parts. We didn't catch this right away. We found a local supplier for fittings and will be using them in the future. They are a bit more expensive but it's worth it.

Also, we reconfigured the fermenter bulkhead and sent out hex nuts and o-rings along with the nipple to ensure ease of assembly.

Some kettles were not passivated IN PROGRESS

We are still trying to determine to what extent this has become an issue. At first it looked like an isolated incident, but now its looking like it might be more than just a couple kettles.

The solution is to repassivate the kettles. When we figure out the extent of the problem, we will decide whether to passivate the kettles ourselves or find an easy way for end-users to passivate them.

ThermoBarrel fitting(s) rusted IN PROGRESS

This was brought up by ingchr1, and I've been communicating with him on possible causes/solutions. So far we haven't heard from anyone else. We have not had the time to check each individual ThermoBarrel bulkhead and we plan on doing this over the next few weeks.

Fermenter clamps not sealing properly RESOLVED

This issue has arisen for two people so far. These lids didn't seal all the way because the clamps weren't bent down far enough. One supporter figured out how to bend them down on their own. We exchanged the other one at no cost to the supporter. In the future, this is something we will have to double check before we send it out, but it's a problem we can fix.

Insufficient packaging for the ThermoBarrel RESOLVED

The few supporters who had dents in their ThermoBarrels from shipping were offered replacements. Most decided that free gear or store credit would be enough to remedy the cosmetic damage to the mash tun.

We have reconfigured the packaging for the ThermoBarrel and don't expect any more serious issues from shipping. Furthermore, we are working on custom designs for all packaging.

-

Of the nine issues listed above one remains unresolved, and two are in progress. It's still not clear how major those two issues are. All the other issues have been remedied in one way or another. Even with no hassle refunds, only one KS backer who saw the equipment in person asked for a refund (drgonzo2k2).

We are planning on sending out a survey to all the Kickstarter supporters to get more feedback about the equipment at the end of the month. Hopefully most people will have had a chance to use their equipment by then. Even though there have been a lot of issues brought up in this thread, I'm expecting the majority of the feedback on the survey to be positive. We are planning to make the results public, and I will post them here when they are.

Make that 3 with the fermenter clamps not sealing. Just figured it out today when I wasn't seeing any bubbles 3 days after pitching and finally opening it up and seeing krausen.

ChapmanEquipment

Active Member

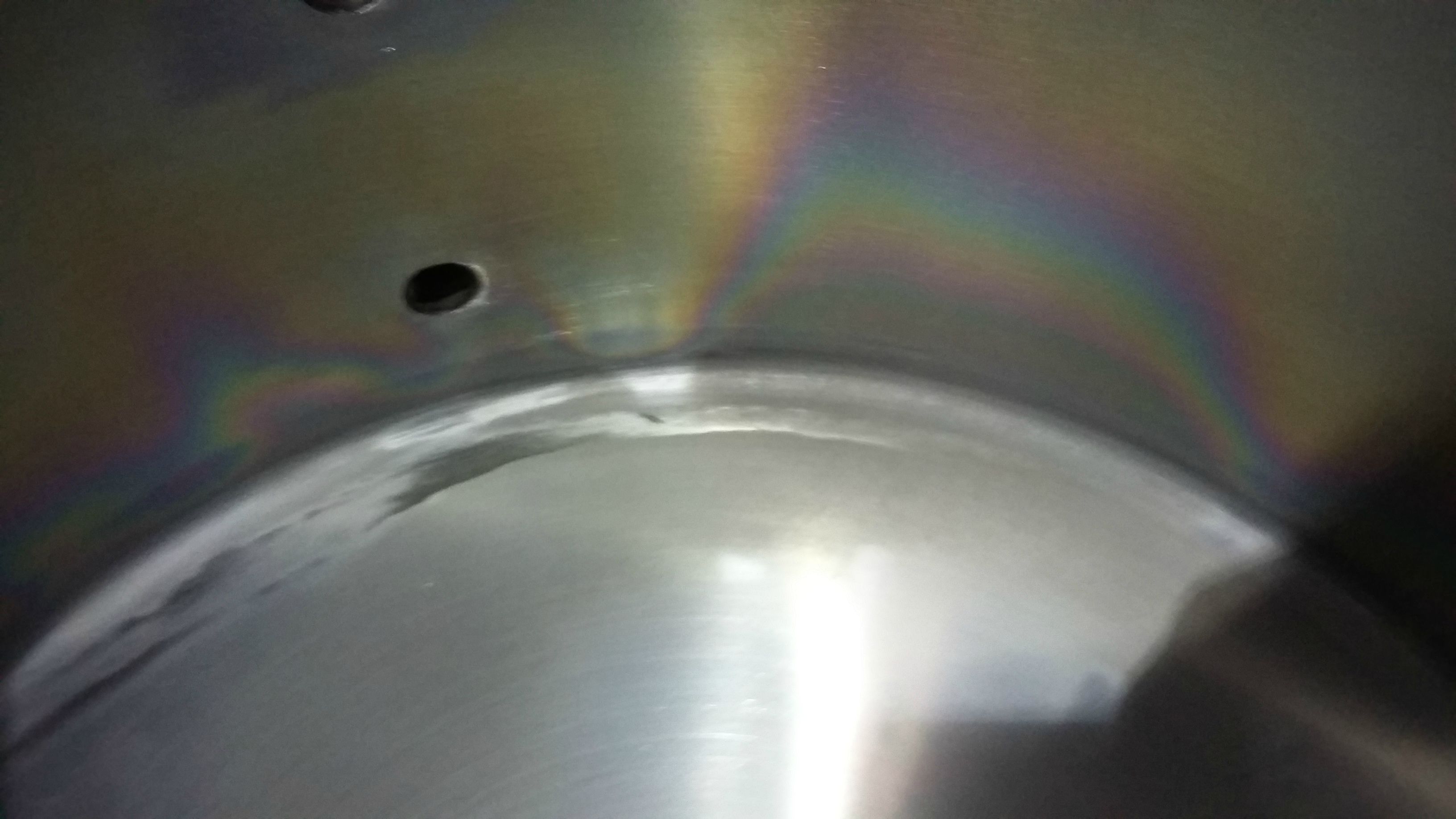

I received the kettle that was returned by drgonzo2k2 last week and have cleaned removed the oxidation with Bar Keepers Friend. I've also found that one of the kettles we test brewed with developed similar discoloration as the pot chewse posted. That also can be cleaned up with BKF. Here are some before and after pictures.

Before

After BKF and a 24 hour water test

Weld torch burn mark

I actually just scratched this one off with my fingernail.

Rainbow discoloration

After a light rinse with BKF, it's good as new.

I believe now would be a good point to start recommending everyone passivate their kettles. Bar Keepers Friend seems to work fine. Also, a citric acid or acetic acid solutions should work as well. I haven't heard of any oxidation issues with the fermenter or the ThermoBarrel. So it's not necessary to repassivate those.

Before

After BKF and a 24 hour water test

Weld torch burn mark

I actually just scratched this one off with my fingernail.

Rainbow discoloration

After a light rinse with BKF, it's good as new.

I believe now would be a good point to start recommending everyone passivate their kettles. Bar Keepers Friend seems to work fine. Also, a citric acid or acetic acid solutions should work as well. I haven't heard of any oxidation issues with the fermenter or the ThermoBarrel. So it's not necessary to repassivate those.

.

Last edited:

- Joined

- Dec 31, 2012

- Messages

- 395

- Reaction score

- 33

@Gavin C,

Thanks for sharing.

The update wasn't for you. Chapman has worked hard to provide forward thinking products with innovative tech. They didn't have the budget to work out all the kinks before opening up their web store front, hence the kick starter.

Other newcomers have not been as transparent.

Quit throwing stones it doesn't raise anyone's game.

-Timur Snoke

Happy ChapmanEquipment 1st gen product owner

Thanks for sharing.

The update wasn't for you. Chapman has worked hard to provide forward thinking products with innovative tech. They didn't have the budget to work out all the kinks before opening up their web store front, hence the kick starter.

Other newcomers have not been as transparent.

Quit throwing stones it doesn't raise anyone's game.

-Timur Snoke

Happy ChapmanEquipment 1st gen product owner

..

totally right point

You're 100% correct. Stupid late night ramblings of mine don't belong in the thread or anywhere for that matter. My apologies.

izzie

Active Member

How much for one of the returned/fixed kettles? I love my fermenter!

ChapmanEquipment

Active Member

How much for one of the returned/fixed kettles? I love my fermenter!

We don't have a plan for selling the refurbished or cosmetically flawed equipment yet. I imagine we will either sell them in person at a warehouse sale or put them up for auction on ebay. I'm pretty busy at this point, so it will probably be a few months before that happens.

izzie

Active Member

it will probably be a few months before that happens.

Dibs.

ingchr1

Well-Known Member

I found out the taller/longer one is for the bottom port, allows for attachment of the dip tube.I wanted to post an update on what I found with the bulkheads. There appears to be two different versions. One is shorter and thinner in the 3/8" portion while the other is taller and thicker.

Bump.

I'm seeing the 15 gallon Thermobarrels are out of stock until April. For those who have the Thermobarrels, have they performed as promised? Are you still happy with your purchases?

The only two things I don't like are no volume graduations and the 3/8" bulkhead portion. I did email Steve about the volume graduations and was told they were left off under the assumption water would be heated up in another vessel that had the volume markings. I can totally understand that. The 3/8" bulkhead portion thing, I still would like more info on. Is the next shipment of 15 gallon tuns going to have true 1/2" bulkheads on it? Is this the reason they are out of stock? What about the ones without all the fittings? I already have Bobby's True bulkheads on my current tun and kettles. Would I still have to modify the Thermobarrels to use them?

I like the idea of a stainless lined "cooler style" mash tun. I have a modified 10 gallon version I made myself and it has been great. The SS Tech tuns look great too, but Chapman is the only one offering a 15 gallon tun. I'm not going to be able to buy anything until spring, so since the 15 gallon Thermos won't be out until April, thought I would ask now.

I'm seeing the 15 gallon Thermobarrels are out of stock until April. For those who have the Thermobarrels, have they performed as promised? Are you still happy with your purchases?

The only two things I don't like are no volume graduations and the 3/8" bulkhead portion. I did email Steve about the volume graduations and was told they were left off under the assumption water would be heated up in another vessel that had the volume markings. I can totally understand that. The 3/8" bulkhead portion thing, I still would like more info on. Is the next shipment of 15 gallon tuns going to have true 1/2" bulkheads on it? Is this the reason they are out of stock? What about the ones without all the fittings? I already have Bobby's True bulkheads on my current tun and kettles. Would I still have to modify the Thermobarrels to use them?

I like the idea of a stainless lined "cooler style" mash tun. I have a modified 10 gallon version I made myself and it has been great. The SS Tech tuns look great too, but Chapman is the only one offering a 15 gallon tun. I'm not going to be able to buy anything until spring, so since the 15 gallon Thermos won't be out until April, thought I would ask now.

ingchr1

Well-Known Member

With as good as their customer service had been, I'm a little surprised there has not been an update on the corrosion issue with the bottom bulkheads. My original had it, then the replacement had it. One would have to assume others have it as well.

Due to this, I ended up modifying the pickup on mine with a upper bulkhead and 3/8" to 1/2" bushing (both I got them to send to me). Luckily I had the rest of the parts on-hand so I didn't have to buy anything new. I have not brewed with it yet, but I just did a leak test this weekend and had 1/4" gallon of dead space.

Due to this, I ended up modifying the pickup on mine with a upper bulkhead and 3/8" to 1/2" bushing (both I got them to send to me). Luckily I had the rest of the parts on-hand so I didn't have to buy anything new. I have not brewed with it yet, but I just did a leak test this weekend and had 1/4" gallon of dead space.

I've used my 10 gallon thermobarrel for a dozen or so batches now, and overall I am still very pleased with my purchase and do not see myself switching out my mash tun again until I go electric and migrate to bigger batches.

I made pretty much the same modification to mine as ingchr1 did, but even with that I think that it leaves a bit too much wort behind when draining. That's not a big deal though as you can account for it in you equipment profiles, but is something to keep in mind.

I had a couple of stuck sparges, but that was probably operator error as it was my first time also using a pump to drain the tun. Since I've started conditioning my malt and backing down the speed of the pump I've not ran into any more issues.

The thing that continues to impress me is how well it holds mash temp once it's been pre-heated and your mashed in. So far the most I've noticed it drop is about .5 degrees over the course of an hour.

I made pretty much the same modification to mine as ingchr1 did, but even with that I think that it leaves a bit too much wort behind when draining. That's not a big deal though as you can account for it in you equipment profiles, but is something to keep in mind.

I had a couple of stuck sparges, but that was probably operator error as it was my first time also using a pump to drain the tun. Since I've started conditioning my malt and backing down the speed of the pump I've not ran into any more issues.

The thing that continues to impress me is how well it holds mash temp once it's been pre-heated and your mashed in. So far the most I've noticed it drop is about .5 degrees over the course of an hour.

.....The thing that continues to impress me is how well it holds mash temp once it's been pre-heated and your mashed in. So far the most I've noticed it drop is about .5 degrees over the course of an hour.

That's the way my "ghetto barrel" has been.

As far as leaving wort behind, could one just use a different false bottom/pick up tube setup? I think Jaybird's has one that fits around a street elbow. Or is it an issue of the valve hole being too high from the bottom of the tun?

I'd still like to know if the 3/8" bore issue is being addressed or going to be addressed. Is this one reason why the 15 gallon tuns are out of stock until April? Maybe Steve will chime in.

ingchr1

Well-Known Member

If my pickup was closer to the bottom it would pick up more. I'm really not concerned with a 1/4 gallon being left behind, my equipment profile accounts for it.As far as leaving wort behind, could one just use a different false bottom/pick up tube setup?

I'm not sure the 3/8" size is an issue per se, as it's designed that way to allow the bulkhead to seal against the inner wall of the barrel.I'd still like to know if the 3/8" bore issue is being addressed or going to be addressed.

Well, again, I performed pretty much the same mod to mine as ingchr1 shows in his picture, which is basically a William's false bottom setup with a street 90 connected to 1/2 silicone tubing.

I gave it one shot with the stock dip tube, didn't really like the results, made the modification, still wasn't terribly happy with the results, but again, you can work around it in your equipment profile, so it's something I live with.

I had only minor issues getting the stock dip tube setup sealed/working properly, but interestingly enough, it worked really well in a cooler mash tun I put it in. Left about the same amount of wort, but no sealing issues.

I gave it one shot with the stock dip tube, didn't really like the results, made the modification, still wasn't terribly happy with the results, but again, you can work around it in your equipment profile, so it's something I live with.

I had only minor issues getting the stock dip tube setup sealed/working properly, but interestingly enough, it worked really well in a cooler mash tun I put it in. Left about the same amount of wort, but no sealing issues.

ingchr1

Well-Known Member

When I did my leak test I also cleaned the barrel so I used hot water. The water covered up to the thermometer. I left it overnight for ~14 hours or so. The temperature dropped 5 degrees over that time, so it does hold temperature just fine. I had 100 degree water in there.The thing that continues to impress me is how well it holds mash temp once it's been pre-heated and your mashed in. So far the most I've noticed it drop is about .5 degrees over the course of an hour.

When I did my leak test I also cleaned the barrel so I used hot water. The water covered up to the thermometer. I left it overnight for ~14 hours or so. The temperature dropped 5 degrees over that time, so it does hold temperature just fine. I had 100 degree water in there.

5 degrees is pretty damn impressive over a 14 hour period. I average about even to a half degree on mine over a 60 minute mash. The worst case has been 1 degree for a low gravity beer.

On another note, with these tuns being made with 201 stainless, would etching volume markings on the inside be a concern? It's not a deal breaker, but just thought I'd ask.

Oh yeah, I was gonna say, like ingchr1 said, when I chatted with Steve he mentioned the 3/8" reduction to ensure a tight seal against the inner wall of the barrel, so I don't know that would change (but then again I don't know for sure they won't either).

I'd imagine they are out of stock now, as everything leftover from the Kickstarter has been sold out, and they've not yet placed a new order with the manufacturer.

If I was in the market now and could either wait and see or go with someone else, honestly I'd probably just go with the 20 gallon SS Brewtech insulated tun and call it good.

I'd imagine they are out of stock now, as everything leftover from the Kickstarter has been sold out, and they've not yet placed a new order with the manufacturer.

If I was in the market now and could either wait and see or go with someone else, honestly I'd probably just go with the 20 gallon SS Brewtech insulated tun and call it good.

Oh yeah, I was gonna say, like ingchr1 said, when I chatted with Steve he mentioned the 3/8" reduction to ensure a tight seal against the inner wall of the barrel, so I don't know that would change (but then again I don't know for sure they won't either).

I'd imagine they are out of stock now, as everything leftover from the Kickstarter has been sold out, and they've not yet placed a new order with the manufacturer.

If I was in the market now and could either wait and see or go with someone else, honestly I'd probably just go with the 20 gallon SS Brewtech insulated tun and call it good.

I'm not going to be able to buy anything until spring, so time is on my side.

I don't know if I want a 20 gallon tun. I'm mostly a 5 gallon brewer, with the occasional favorite being a 10 gallon batch, and that favorite being done just once.

Similar threads

- Replies

- 6

- Views

- 592

- Replies

- 2

- Views

- 695

- Replies

- 2

- Views

- 622

- Replies

- 4

- Views

- 1K