When fermenting, I start off by placing fermenter in a kettle in the batub with cold water + ice (when needed) to keep it at 65. Once that's finished, I store fermenter at 68 for a week minimum. Should I trust co-pitching enough when I want to assure it gets to 3.2-3.3?

My gose-inspired beer with US-05 I co-pitch with plantarum and ferment at 66-67. It's thoroughly soured and finished fermenting on day 5 and then I package it with a hop tea. I love the flavor I get from hop tea; I'm surprised this technique isn't more widely used.

Dry hopping is a good option as well. One regular here (sorry, I forgot who) has experienced flavor issues with dry hopping a low-pH beer, but my experience is that it's fine and it's definitely not a common complaint.

Hops increase foam.

Sour taste is a lot more accurately measured not TA, not pH (and perception is affected by other factors), but yes, pH will pretty much bottom out within a week, although sourness can continue to develop over an additional week if hops aren't added.

L. plantarum does a great job souring quickly at room temp; lots of people can tell you that.

If you add fruit, that will directly contribute other organic acids.

The co-souring method does seem very easy though. Basically, no boil necessary. On the FAQ, you say you don't need to pre-acidify, but on this thread you say you do. Which is it?

I boil my beer (

before souring) in order to get good break removal, fining, DMS removal, and for the ease of sanitation, etc, but it is an optional step.

Boiling

after souring is not needed, and neither pre-souring nor boiling after souring are beneficial in my opinion.

I did make one no-boil sour (with a decoction to mash out) but I didn't detect any noticable flavor improvement vs boiling.

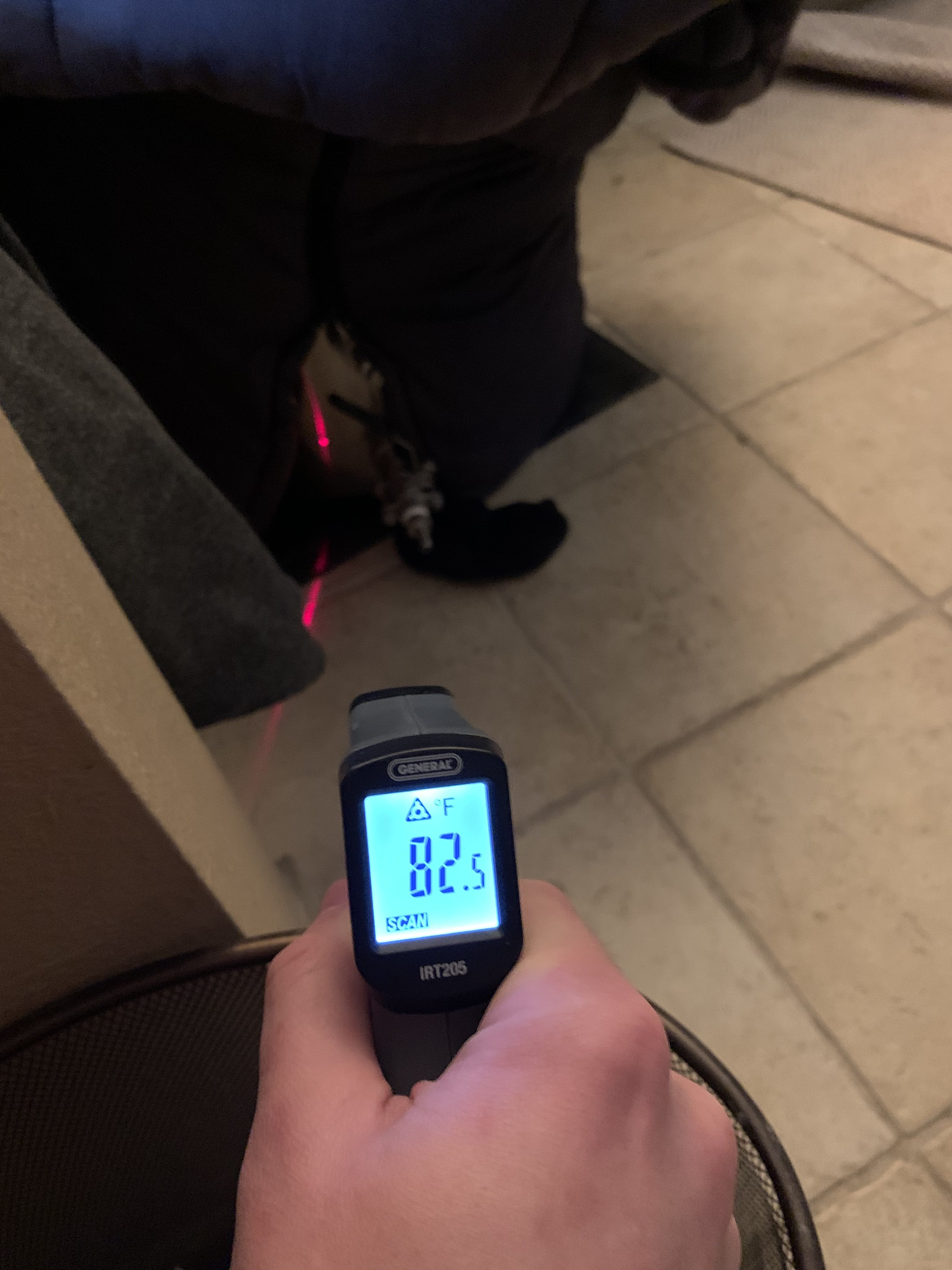

If you choose not to boil at all, sanitizing the chiller with a no-rinse sanitizer is an option if your chiller is thoroughly cleaned beforehand, or you can use hot water (>150°F for 10-15 minutes or so). If you're using an immersion chiller, you can stick it in your MLT to let the mash sanitize it.

For best foam retention, it's helpful to have the pH below 4.5 when you pitch the Lacto. Lactobacillus degrades the proteins responsible for head formation, but the enzyme activity appears to diminish in this lower pH range.

The MTF link I posted provides a good visual for this phenomenon.

Personally I've always been focused on flavor over appearance, so I consider pre-acidification to be an optional step for any method of souring (except in the case of adding wild microbes to unhopped wort). The other reason I consider pre-acidification to be an optional step is that it doesn't always work. Many people still struggle to get good head retention even though that's one of their goals.

An unbuffered Lacto starter should be able to accomplish most or all of the pre-acidification, as

@isomerization mentioned. I buffer my starters to achieve a vastly higher cell growth, so I can't speak to that from experience.

Long term sours likely lose head retention because of the proteinase release caused by yeast autolysis (this is known to happen in non-sour beer) in addition to bacterial activity.

I think adding fresh DME wort later is not a bad idea (it's a hack I wouldn't use, but I don't doubt that it works). I believe commercial breweries achieve good head by blending the sour beer with younger and/or non-sour beer.

Hope this answers your questions.

P.S. The flavor produced by bacteria with a low-oxygen brew process is amazing beyond words and something I've never experienced in a commercial beer.