- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

Recently I built a collar keezer. My set up for 10 corny kegs And has 4 intertap faucets.

I've been trying to carb up a cream ale for several weeks with no luck.

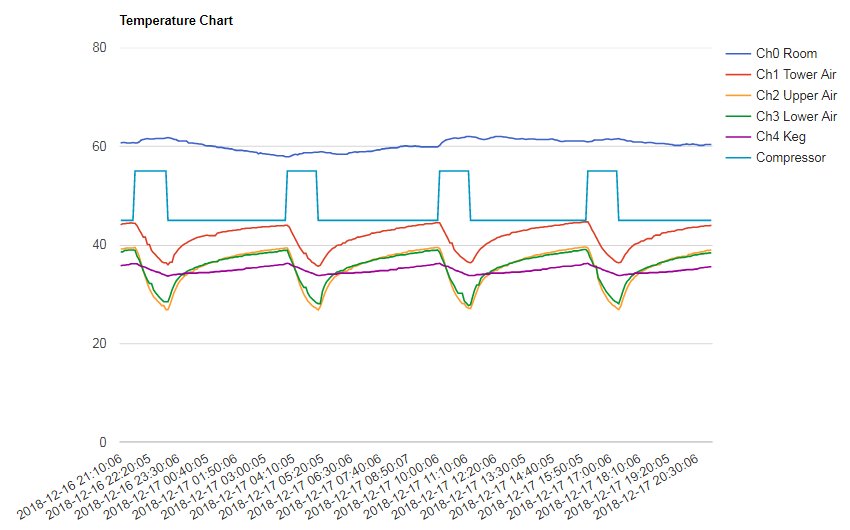

I keep the keezer set to 38f +-2f. I've got my temp probe hot glued into a 20oz Coke bottle full of water. I set the bottle square in the middle of the keezer on the floor. I've got a fan circulating, pulling air from the bottom and pushing it across the top of the kegs.

8 of my kegs are set at 15psi and seem ok. The two cream ale kegs I had at 15psi for 2 weeks and have progressively increased the psi to 28psi and held it there for 3 days. I would expect it to be way over carbed but unfortunately it seems very flat. Maybe 1vol co2.

I started thinking about what could cause this. So I checked the temp if the beer coming out of the tap. 55f. That's 15f higher than my temp controller is telling me it should be.

So what can I do?

The two on the hump are the ones I'm having trouble with. But all of them seem to be pouring at 50f+ (tho the others are seemingly carbed up ok)

I've been trying to carb up a cream ale for several weeks with no luck.

I keep the keezer set to 38f +-2f. I've got my temp probe hot glued into a 20oz Coke bottle full of water. I set the bottle square in the middle of the keezer on the floor. I've got a fan circulating, pulling air from the bottom and pushing it across the top of the kegs.

8 of my kegs are set at 15psi and seem ok. The two cream ale kegs I had at 15psi for 2 weeks and have progressively increased the psi to 28psi and held it there for 3 days. I would expect it to be way over carbed but unfortunately it seems very flat. Maybe 1vol co2.

I started thinking about what could cause this. So I checked the temp if the beer coming out of the tap. 55f. That's 15f higher than my temp controller is telling me it should be.

So what can I do?

The two on the hump are the ones I'm having trouble with. But all of them seem to be pouring at 50f+ (tho the others are seemingly carbed up ok)