It's that time again! Time for yet another brew rig build.

Design Considerations

I've ordered the rest of the fittings and they should be delivered this week. I'll update this thread then with more information on the plumbing and how the system operates.

Until then, it isn't much more than a simple brew stand.

The Stand

For this first iteration, I decided to build the stand out of 2x4s. Total cost was about $30 and it took about a day to build (if you know what you're doing, I imagine it'd go a lot faster). I used some stain left-over from a previous project. I plan to finish it with some spar urethane.

The top of the stand is made from a 2'x4' sheet of 3/4" plywood. Home Depot sells lots of 2'x4' "hobby sized" plywood, so that meant one less thing to cut on the table saw.

I plan to place large ceramic tiles under the mash tun and boil kettle. I've been brewing on another wooden table for a while now and I've found this provides a more than adequate level of insulation.

The casters are from Harbor Freight, are rated for 200lb, and can be locked.

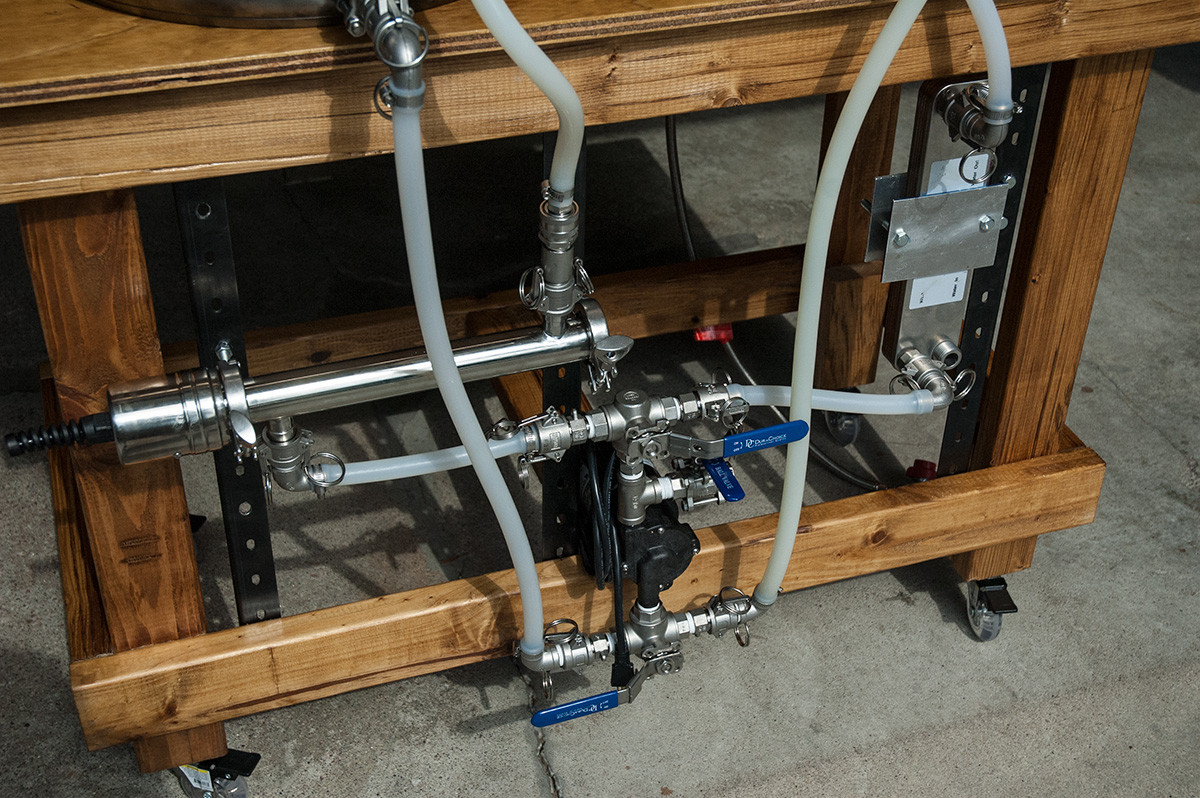

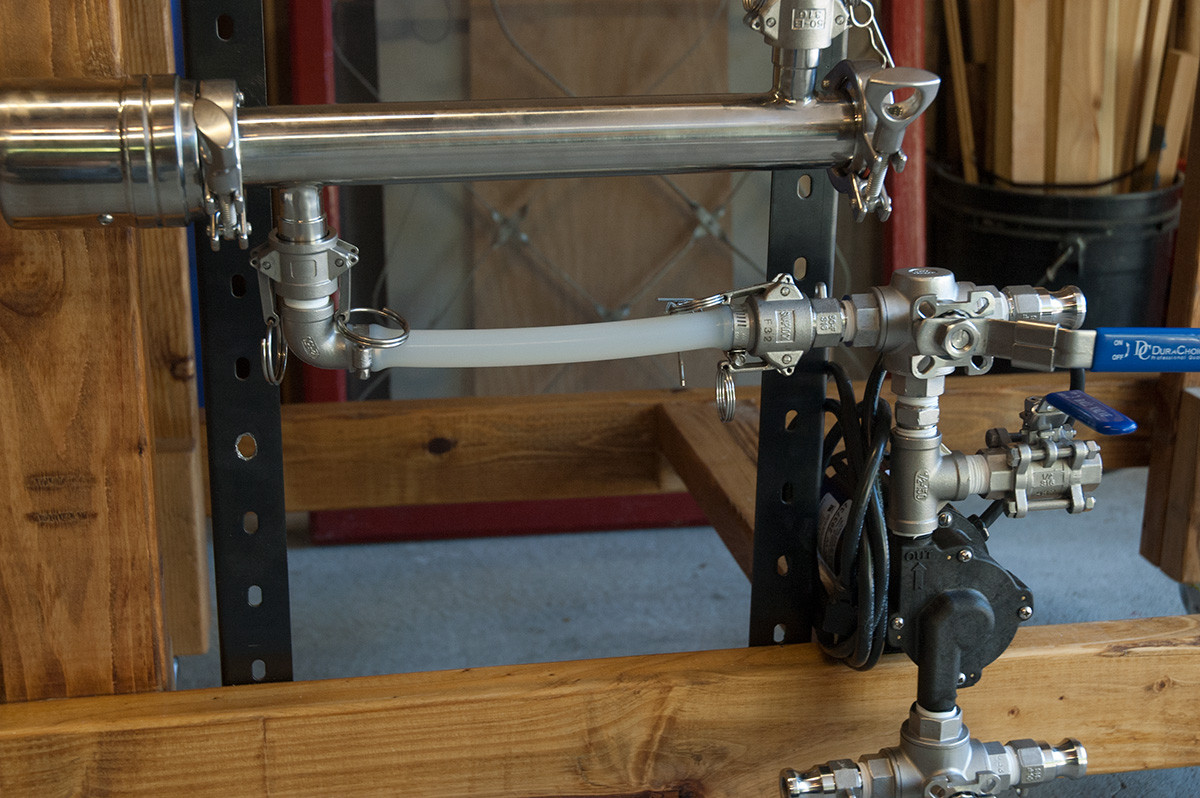

The metal rails began their life in a 19" rack. I found 'em in a pile of scrap in the garage and cut them to size with a hacksaw. They're very rigid. The RIMS tube will attach to the left rail with 2 1/2" bolts and jam nuts, and the plate chiller will attach to the right rail.

Everything is glued and screwed with 2 1/2" deck screws. The rails and pump are attached with large hex-head wood screws.

Design Considerations

- Keep it simple

- 10 gal capacity

- No swapping hoses

- Single tier, single burner, single pump

- Easy to clean

I've ordered the rest of the fittings and they should be delivered this week. I'll update this thread then with more information on the plumbing and how the system operates.

Until then, it isn't much more than a simple brew stand.

The Stand

For this first iteration, I decided to build the stand out of 2x4s. Total cost was about $30 and it took about a day to build (if you know what you're doing, I imagine it'd go a lot faster). I used some stain left-over from a previous project. I plan to finish it with some spar urethane.

The top of the stand is made from a 2'x4' sheet of 3/4" plywood. Home Depot sells lots of 2'x4' "hobby sized" plywood, so that meant one less thing to cut on the table saw.

I plan to place large ceramic tiles under the mash tun and boil kettle. I've been brewing on another wooden table for a while now and I've found this provides a more than adequate level of insulation.

The casters are from Harbor Freight, are rated for 200lb, and can be locked.

The metal rails began their life in a 19" rack. I found 'em in a pile of scrap in the garage and cut them to size with a hacksaw. They're very rigid. The RIMS tube will attach to the left rail with 2 1/2" bolts and jam nuts, and the plate chiller will attach to the right rail.

Everything is glued and screwed with 2 1/2" deck screws. The rails and pump are attached with large hex-head wood screws.

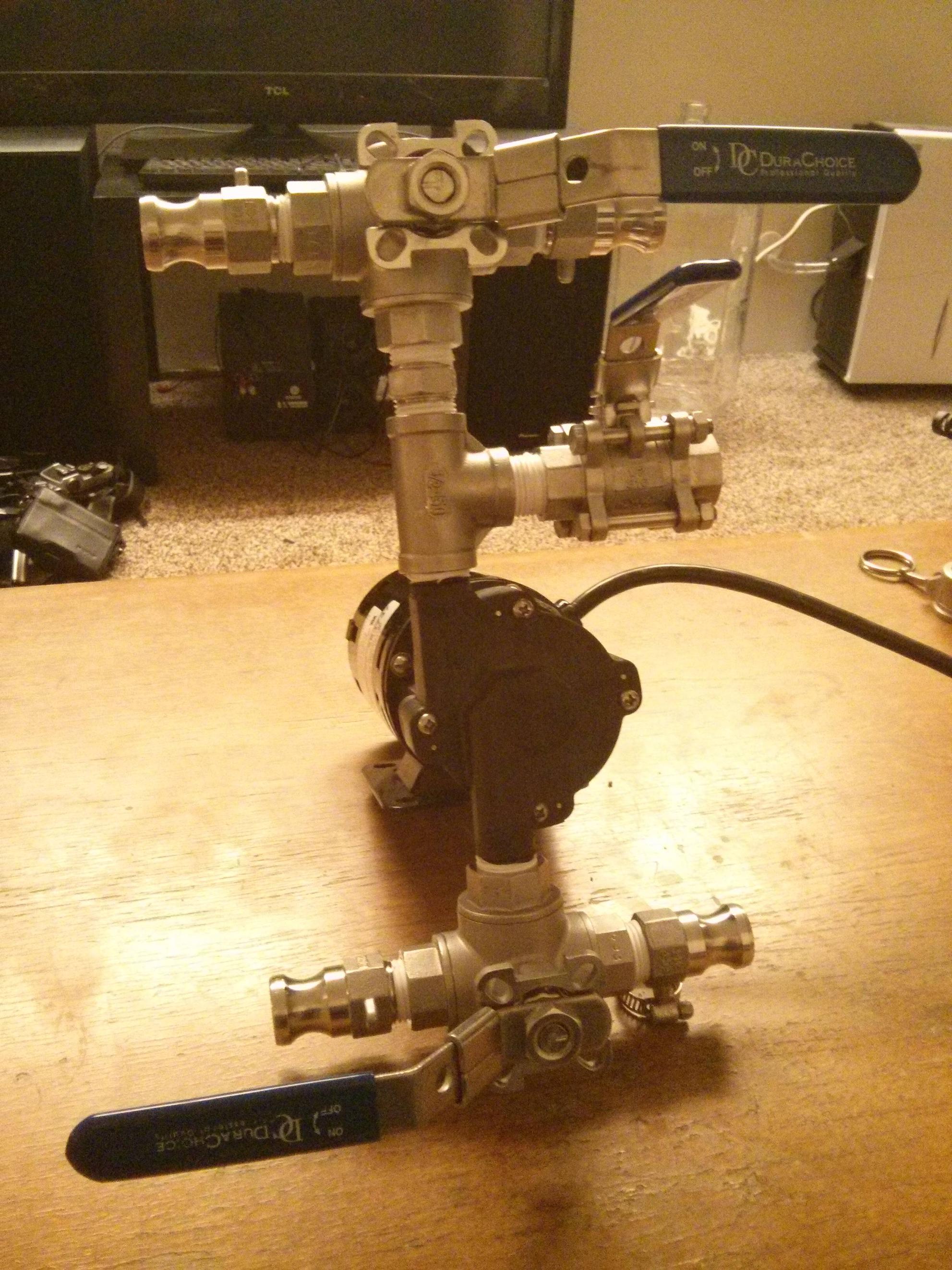

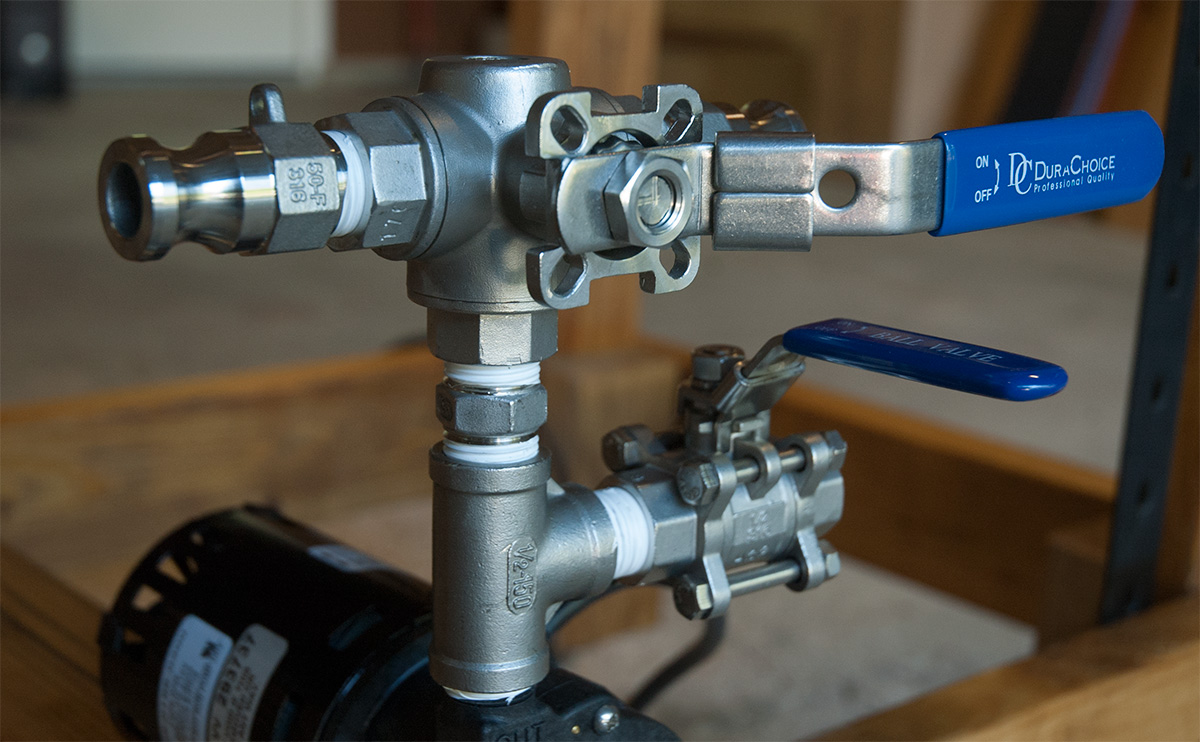

), shorten up a couple hoses, attach a few hose clamps, double check all my connections, and check for leaks.

), shorten up a couple hoses, attach a few hose clamps, double check all my connections, and check for leaks.