Travis K. Jansen

Well-Known Member

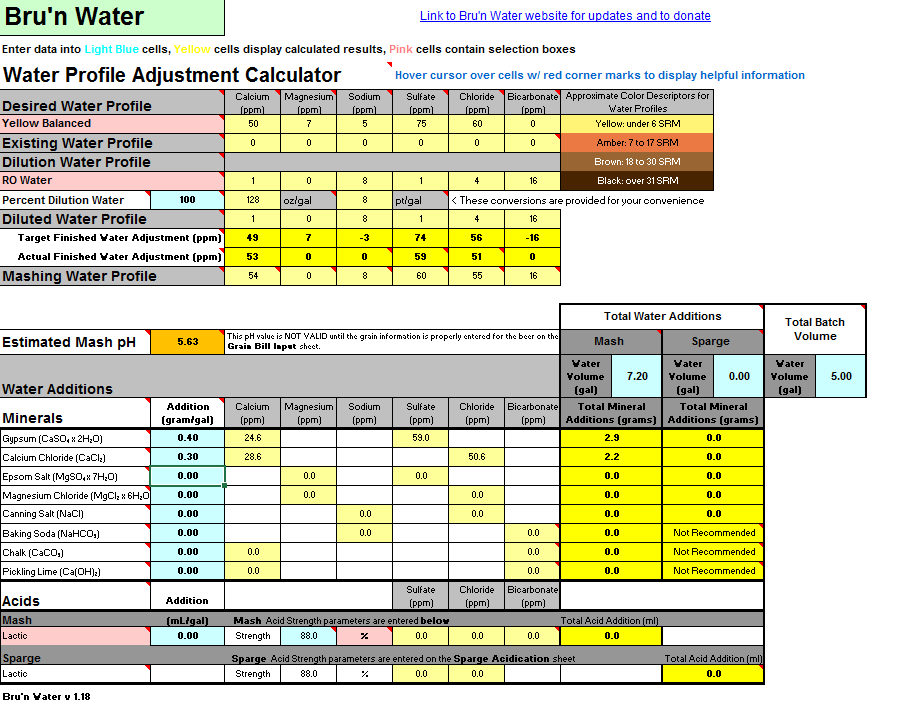

So I downloaded the spreadsheet, and I'm hoping someone can help me make just a little sense of what i'm looking at. I'm brewing a Spotted Cow clone, cream/kolsch style of course, so I picked Yellow Balanced (Yellow Malty mentioned on the forums, but not available in this sheet?)

I'm starting with RO water, and basically I've been reading that I need to get soft water. I have CaCl and Gypsum on hand. Referring to this image below:

1.) There are seemingly 4 rows that I see important. Am I interpreting this right?

Yellow Balanced row at the top shows what we're aiming for

Target finished water vs. Actual finished water, don't exactly know how these differ

Mashing Water profile

I'm guessing I want my mashing water profile row to match as closely as I can to the top "Yellow Balanced" row.

2.) With only gypsum and cacl, are my numbers in the additions section close enough?

Thanks! Excited to get better at brewing additions with RO water.

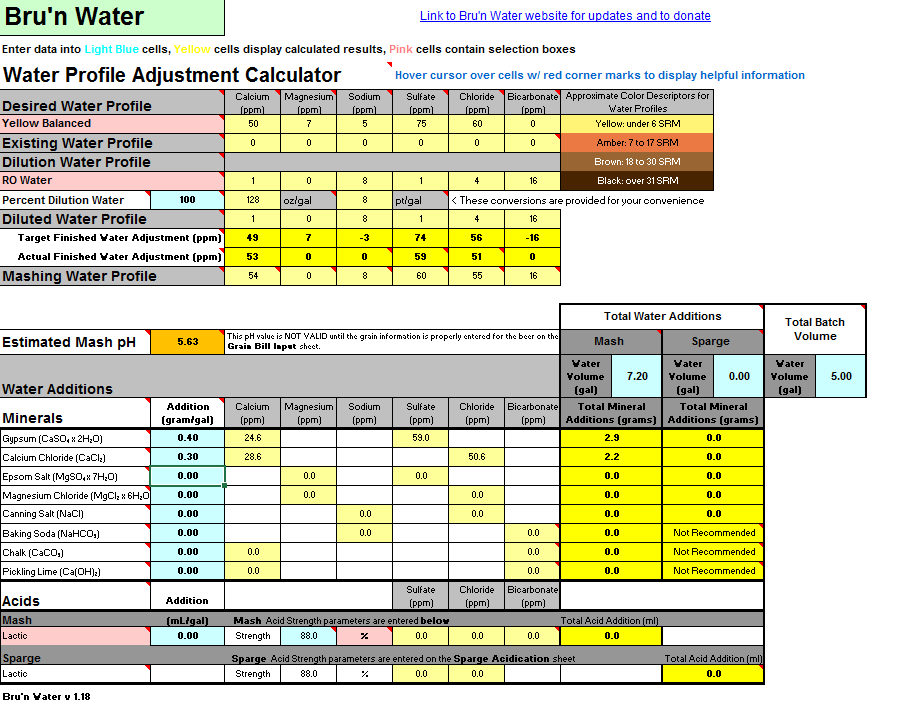

I'm starting with RO water, and basically I've been reading that I need to get soft water. I have CaCl and Gypsum on hand. Referring to this image below:

1.) There are seemingly 4 rows that I see important. Am I interpreting this right?

Yellow Balanced row at the top shows what we're aiming for

Target finished water vs. Actual finished water, don't exactly know how these differ

Mashing Water profile

I'm guessing I want my mashing water profile row to match as closely as I can to the top "Yellow Balanced" row.

2.) With only gypsum and cacl, are my numbers in the additions section close enough?

Thanks! Excited to get better at brewing additions with RO water.