I just dumped a batch of perfectly good wort after a 3 hour brewday because the pos clamps on my immersion chiller gave way and water sprayed in the wort. I had two clamps on that line too. It was a beer with 8 ounces of hops in the boil, so I'm out a pretty penny in hops and will have to reorder in bulk... It seems like my Christmas beer for this year will not be an IIPA.

I was lucky that I was right next to the pot when it happened since I was chilling wort INSIDE the house for the first time today, so I caught it before the damn thing overflowed.

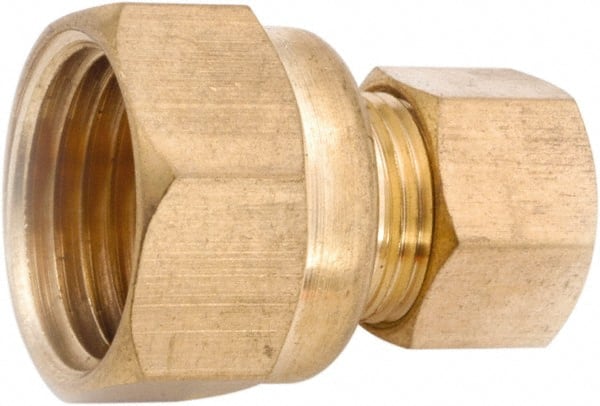

Is there any way around using those stupid clamps that always come loose and make the hose leak on an immersion chiller ? I have used both butterfly clamps and oetiker clamps, and both have resulted in a one failure each. It's always the goddamn 30 cents part that fail.

I was lucky that I was right next to the pot when it happened since I was chilling wort INSIDE the house for the first time today, so I caught it before the damn thing overflowed.

Is there any way around using those stupid clamps that always come loose and make the hose leak on an immersion chiller ? I have used both butterfly clamps and oetiker clamps, and both have resulted in a one failure each. It's always the goddamn 30 cents part that fail.