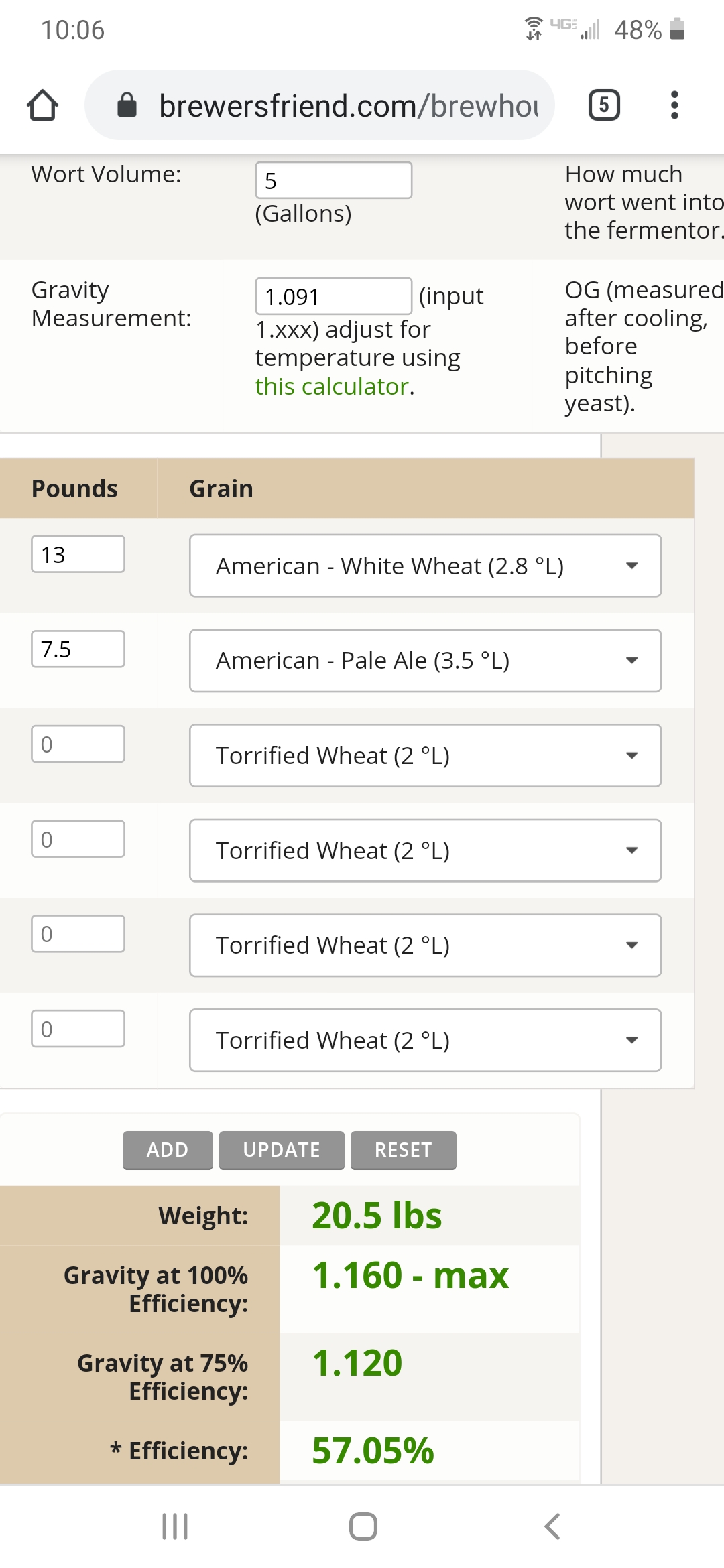

I see a similar thread here which gave me some ideas but I wanted to start my own. Today I finally got to brew again and did a 5g batch of a Wheat Wine. It appears my mash was only 57% and I'm wondering what might be the cause or what is most likely the cause. I have another big beer planned next week so I hope to maybe apply some changes for the next batch. Here are my thoughts on the issue:

- This recipe had 13 out of 20.5 lbs of white wheat malt. I'm reading that maybe I should have double crushed that. So the wheat could be one problem. Next time I have a wheat beer maybe I should double crush as a general rule.

- My mill is set to .038" and since I don't recirculate anymore I could double crush just as normal routine. My 3 roller monster mill will get stuck sometimes so I don't think narrowing the gap is an option. But double crush should be pretty easy I've just never tried it.

- My rig is electric and has a false bottom to protect the bag. The 20g kettle has probably 4g under the false bottom that the grains never see. So when I mashed in with 8.95 gallons it was more like 4.95 gallons with 20.5 lbs of grain. That puts the mash really thick. My other idea is when doing high gravity 5g batches, do a 90 minute boil just to get the extra water for the mash.

- I do have a ph meter but I've been not using it lately so another idea is to make sure the ph isn't out of control. But I never had issues so I left that step out just to make things more enjoyable.