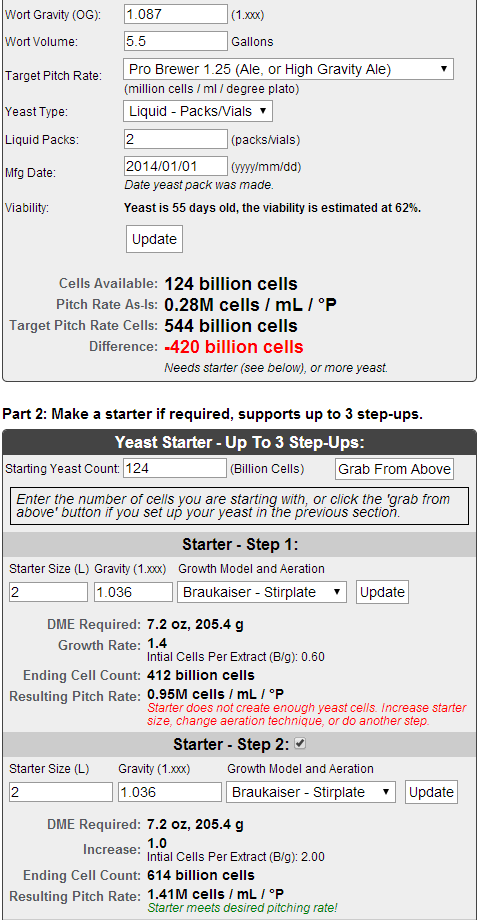

I received delivery of my ingredients from an online store and found the 2 yeast packs they shipped are over 2 months old. According to MrMalty and Brewersfriend, that equates to about 47% viability and for the 5.5 gal/1.087 batch I'm planning, I'll need to pitch both packs into ~ 3L starter or do a step up (519 billion cells required). I have a 2000 ml flask and a growler and one stir bar. Here's what I'm thinking:

1. Put both yeast packs into 1.6L wort in the flask and ferment on the stir plate for 24 hours with foil on top

2. After 24 hours, make up another 1.6L of wort

3. Pour 1/2 of the fermenting starter into the growler and add 1/2 of the new wort to it, cover with foil and shake intermittently for 24 hours

4. Add the rest of the new wort to the flask and put it back on the stir plate.

5. Brew and pitch both starters without decanting

Is this a sound plan? Any suggestions?

1. Put both yeast packs into 1.6L wort in the flask and ferment on the stir plate for 24 hours with foil on top

2. After 24 hours, make up another 1.6L of wort

3. Pour 1/2 of the fermenting starter into the growler and add 1/2 of the new wort to it, cover with foil and shake intermittently for 24 hours

4. Add the rest of the new wort to the flask and put it back on the stir plate.

5. Brew and pitch both starters without decanting

Is this a sound plan? Any suggestions?