Finlandbrews

Well-Known Member

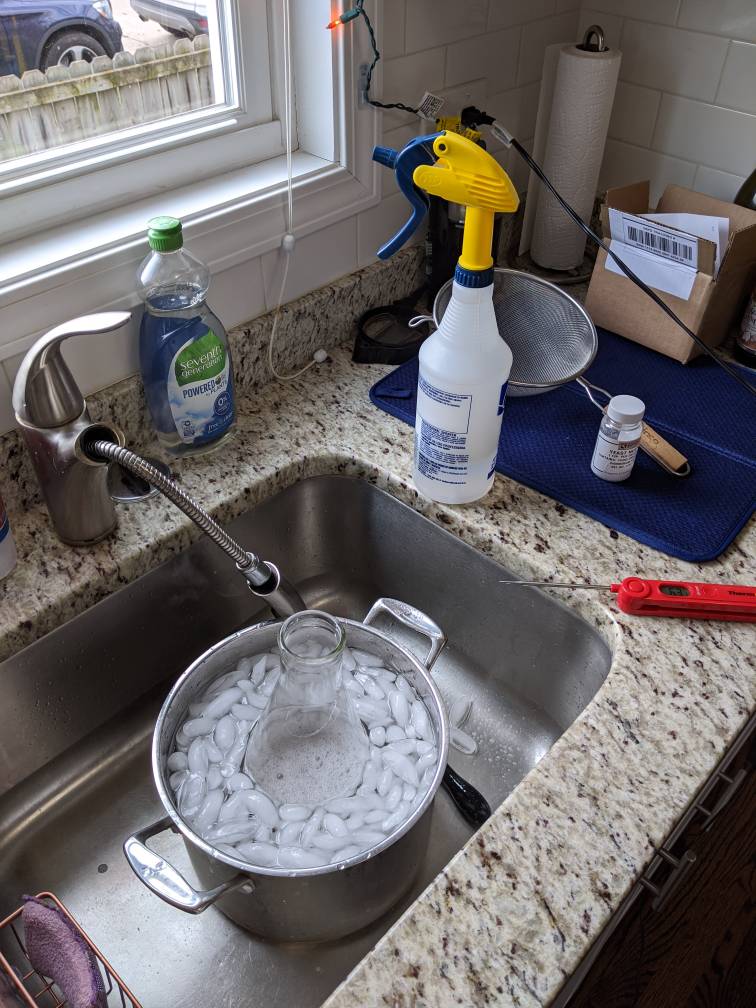

Is temperature control as important during preparation of a yeast starter compare to during fermentation? What should be the temperature of a yeast starter for an ale and lager strain? Does it make sense to make a starter at same temperature as the one planned during my fermentation or just the temperature at which I will get the healthiest yeast?