You might keel over before creating 2" of foam! Plus, you'd have to gargle with StarSan.

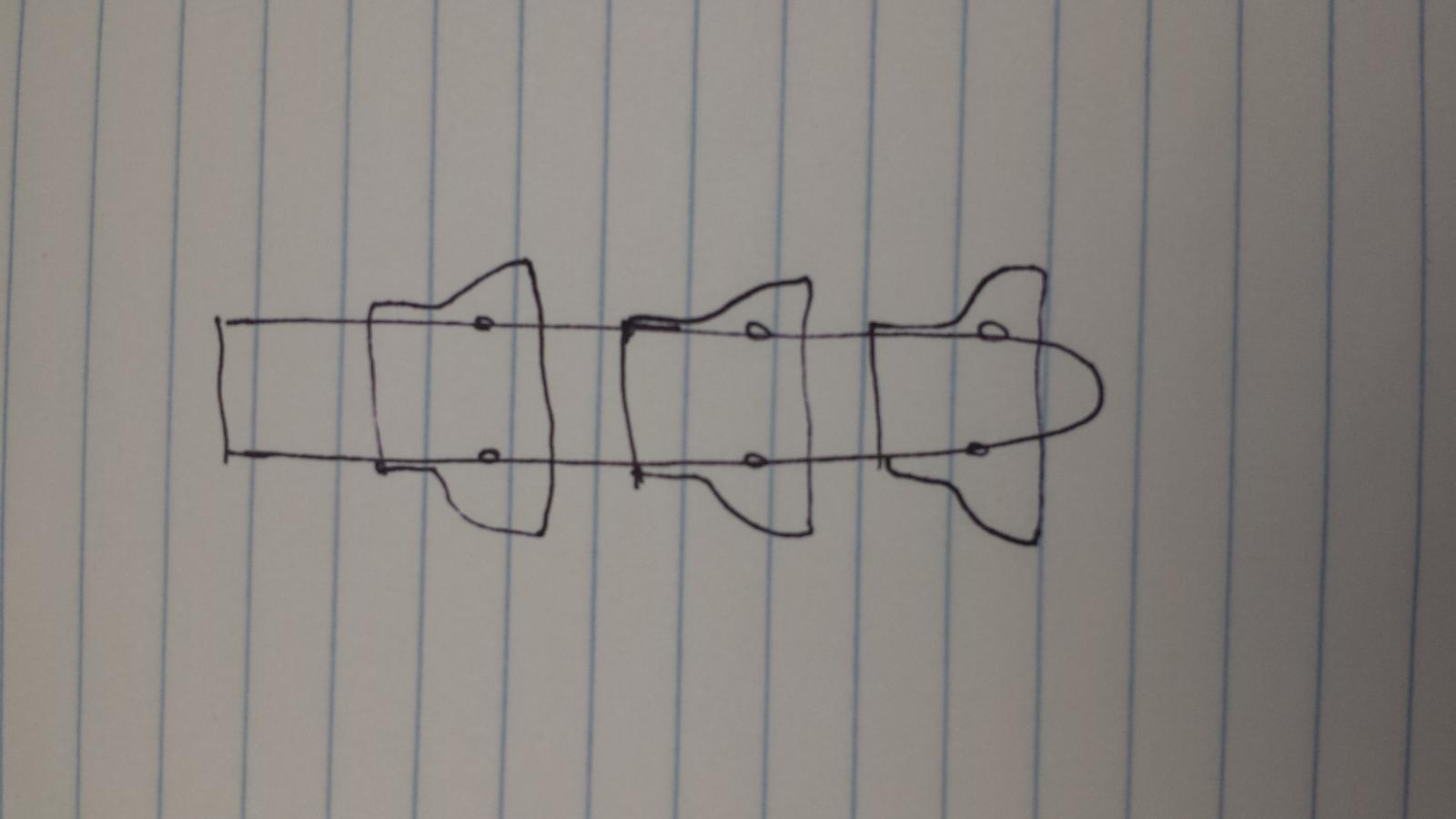

Or blow through one of these. Be interesting to see how many germs make it through the filter.

You might keel over before creating 2" of foam! Plus, you'd have to gargle with StarSan.

Or blow through one of these. Be interesting to see how many germs make it through the filter.

You might keel over before creating 2" of foam! Plus, you'd have to gargle with StarSan.

Hmm, I wonder how that would work. Listerine prices keep going up... Maybe the Sanstar people have another market!

Ok, so I brewed an IPA today with an OG of 1.058.

I chilled the wort to 62f and poured 5.5 gallons through a SS strainer into a 6.5 gallon fermentation bucket. Additionally, this was my original method for aerating my wort.

I took a sample of this wort and then stuck the SS wand from my new aeration set up (which uses the small hardware store O2 tanks) into the previously strained wort and shot oxygen for 60 seconds through a 2 micron diffusion stone.

I ran the samples down to the waist water treatment facility for a test on dissolved oxygen.

Sample #1 measured 3.57 ppm

Sample #2 measured 14.31 ppm

This has been discussed before. It's possible to pitch enough yeast that you don't have to aerate (and some fringe folks do advocate doing so). However the growth creates intermediary compunds that are important for flavor, and especially in a yeast-forward beer like a Belgian you're going to destroy the ester character that way. Even a lager can taste dull if you go to extremes.

The way i see it, with all the extensive research that has been done into pitching rates and aeration in the last half century, i doubt there's a better route than what is already recommended.

The takeaway from all of this is that if you are pitching an adequate amount of (unrinsed) healthy yeast from a starter or recent healthy fermentation, you do not necessarily need to aerate at all. If your yeast is not healthy or there are not enough cells, you will benefit from some aeration.

Minus the disposable O2 tank I had $40.00 into my set up but could have done it for under $30.00.

My LHBS got me a dip tube from an old keg that I used for a wand and I needed a couple fittings to set it up that way which added $10.00 to the cost.

I was clearly getting less than half the recommended O2 I needed so I'm glad I went this route.

It will be interesting to see how my beer benefits from it.

Okay great, so with a starter I should still continue to aerate. Thanks!

Hmmm, now I'm confused again. This was my original thought as well. Why would aeration be needed if you're pitching enough healthy yeast?

"Enough" is the term. It's a variable that can be adjusted. The rates you get from all the yeast calculators I'm aware of are based off of 0.75 (ale) or 1.5 (lager) million cells per milliliter of wort per °Plato. Those are rates that will require aeration, and are rates that, with proper aeration and fermentation temperature, produce good ester profiles (not over the top in ales, and suitably clean in lagers). Increasing pitching rate above those rates would reduce the need for aeration to facilitate growth, but will also suppress esters. For lagers, may not be an issue unless you go to the ultimate extreme (Jamil Zainasheff did an experiment where he fermented a lager with a big enough yeast pitch that the yeast didn't need to grow, and beyond clean it went to dull and lifeless), but for yeast-forward beers where esters are a fundamental part of the style, it could be a problem.

The olive oil thing is a workaround. The ultimate point of oxygen in the wort is to allow yeast to build up sterols, and the olive oil adds the compound(s?) yeast need to do so, bypassing the need for oxygen. But the amounts you need for that are so miniscule compared to the batch size that it's not easy to do for a homebrewer (as noted, even a single drop of olive oil is too much for a 5 gallon batch, I would assume that a saturated toothpick is too much as well but no data to back that up). I wasn't aware of trub or dead yeast doing the same thing and would be curious to see the source (not saying it's wrong, just wasn't aware of it). However, pitching on an unwashed cake is going to be an overpitch for just about anything, and again suppress the esters of the beer.

So point is, if you're brewing an English beer or a Belgian beer, or anything where you want some esters, I wouldn't go the "pitch a whole bunch of yeast and don't aerate" route. For a clean beer (lager, Scottish Ale, etc) then it may work a little better for you.

I use a sanitized paint mixer and a drill. Never had a problem

For my first brew, I will be using a paint stir attachment for a drill in the kettle.

Ok, so I brewed an IPA today with an OG of 1.058.

I chilled the wort to 62f and poured 5.5 gallons through a SS strainer into a 6.5 gallon fermentation bucket. Additionally, this was my original method for aerating my wort.

I took a sample of this wort and then stuck the SS wand from my new aeration set up (which uses the small hardware store O2 tanks) into the previously strained wort and shot oxygen for 60 seconds through a 2 micron diffusion stone.

I ran the samples down to the waist water treatment facility for a test on dissolved oxygen.

Sample #1 measured 3.57 ppm

Sample #2 measured 14.31 ppm

It is possible to over-oxygenate wort.

For my first brew, I will be using a paint stir attachment for a drill in the kettle.

I use a sanitized paint mixer and a drill. Never had a problem

I started out using that, but found that after just a few brews, it was rusting pretty badly. I switched to a "Fizz-X" wine de-gassing rod (stainless steel shaft with hard plastic arms) and it's worked great ever since.

It is possible to over-oxygenate wort. 14.31ppm may be over that line. May be way over that line.

Yes, but with a "but." I've read that you can only "over-oxygenate" wort if you're using pure oxygen (i.e., with an aeration stone). I don't believe it's possible to "over-oxygenate" using shaking, stirring, or splashing. I believe that the most you can get with those methods is 8 ppm, which is more than enough for most beers. Lagers and high-gravity beers may require more, but you needn't worry about "over-oxygenating" if you're using a paint-stirrer or a wine-degasser, or splashing, etc. Just pure O2.

I think most home brewers that use pure O2 are more likely to suffer the effects of over oxygenation rather than under oxygenation. This Is particularly true for beers with a rather low to mid OG.

What is over oxygenated? Say for low gravity, medium gravity and high gravity beers?

I know it is possible because I have seen it written by credible sources but even those sources don't elaborate as to what those numbers are.

Enter your email address to join: