adhd-brouwerke

Member

here's my homemade glycol cooler made from an old red bull cooler that a friend of mine had standing in his new coffee shop, the old owner left it and he didn't have a use for it and wanted to get rid off it. who could say no to such an offer right?

and at work i found a brand new 80L stainless steel tank in the scrap bin so i asked my boss if i could have it.

so the glycol cooler was born in my head.

after stripping it down to its guts this is what i was left with

https://lh3.googleusercontent.com/a...9UefYYm4yoYVAx7tVWyuXiviCAhC5Tnq=w578-h770-no

so i cut a slot in the top of the tank so i was able to fit the radiator inside of the tank and welded the tank to the cooler chassis with some left over stainless tubing i had laying around.

so fast forward a couple off months i decided to make the thing run on a brewpi and gathered all the parts and started making it like the tread here on homebrew talk and this is what i ended up with

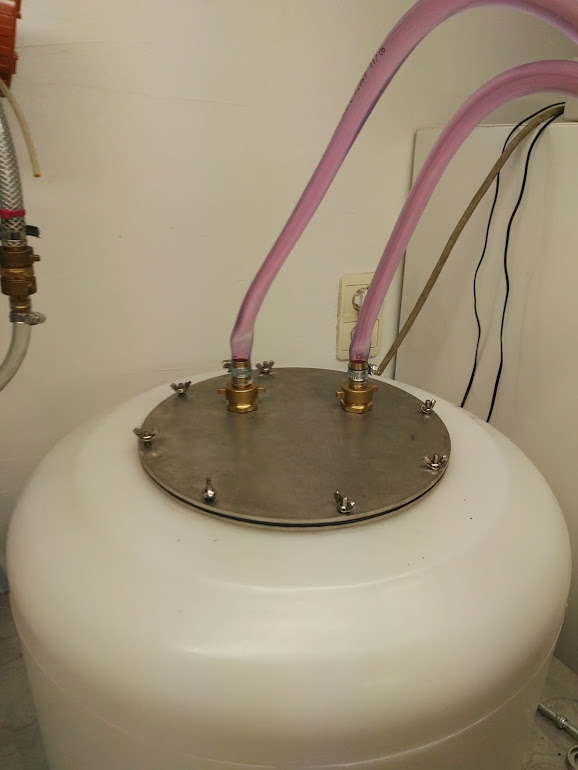

here's the whole thing wrapped in insulation and all the pumps are connected. with te option ta attach one more cooling spiral if a want to at a later time

i'm still test running for leaks for a day or 2 and then test it in a fermenter with water before for a week or 2 before i use it with beer.

i ran in to a problem with the new brewpi screw in temp sensors so i removed them and wil use the old sensors for the time being.

and at work i found a brand new 80L stainless steel tank in the scrap bin so i asked my boss if i could have it.

so the glycol cooler was born in my head.

after stripping it down to its guts this is what i was left with

https://lh3.googleusercontent.com/a...9UefYYm4yoYVAx7tVWyuXiviCAhC5Tnq=w578-h770-no

so i cut a slot in the top of the tank so i was able to fit the radiator inside of the tank and welded the tank to the cooler chassis with some left over stainless tubing i had laying around.

so fast forward a couple off months i decided to make the thing run on a brewpi and gathered all the parts and started making it like the tread here on homebrew talk and this is what i ended up with

here's the whole thing wrapped in insulation and all the pumps are connected. with te option ta attach one more cooling spiral if a want to at a later time

i'm still test running for leaks for a day or 2 and then test it in a fermenter with water before for a week or 2 before i use it with beer.

i ran in to a problem with the new brewpi screw in temp sensors so i removed them and wil use the old sensors for the time being.