homebrewdude76

Well-Known Member

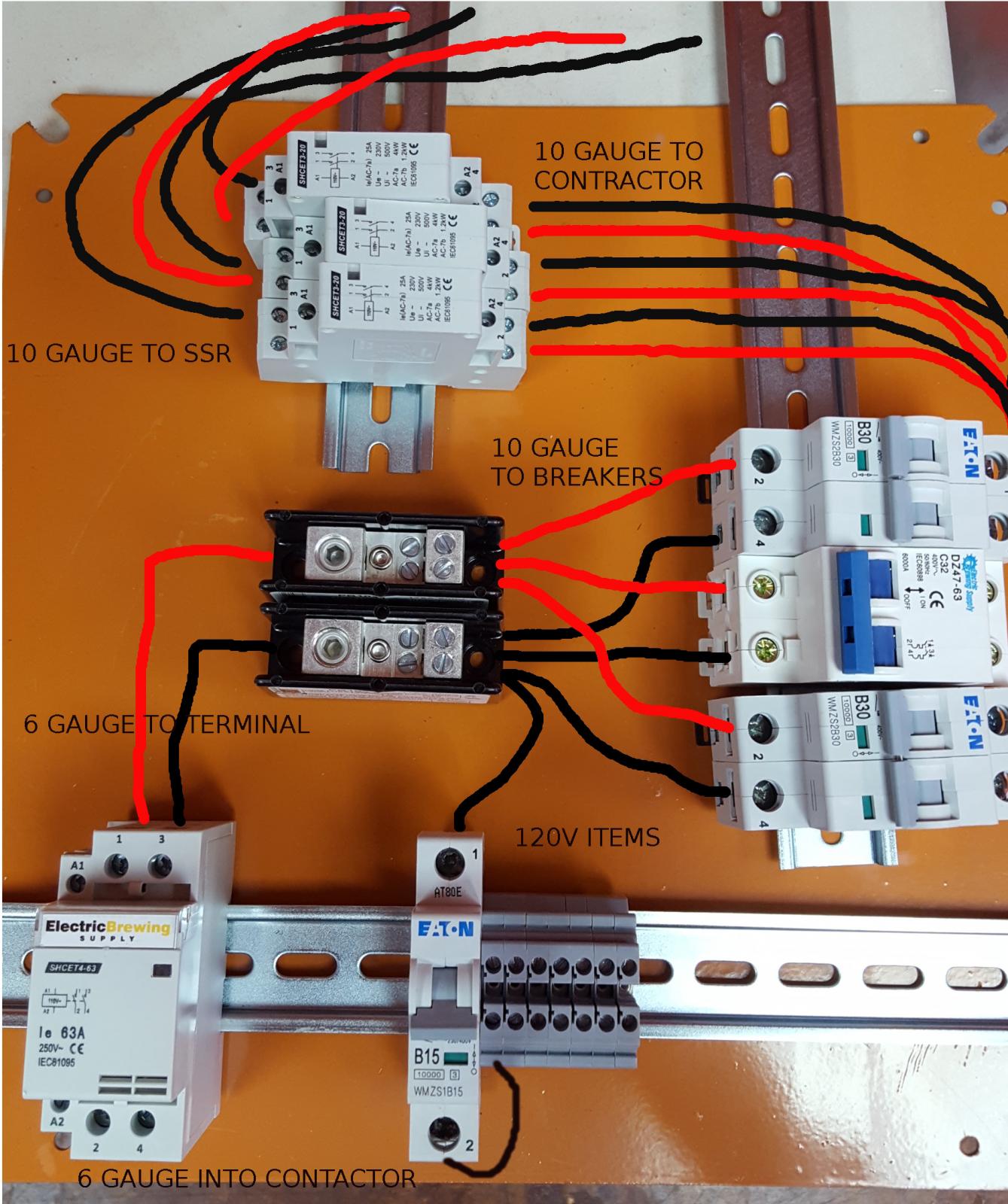

I have been planning and thinking about this for some time.

Looks like I will start on the panel.

Planning on 50amp with options to run 3 elements, 5 temp probes and 3 pumps.

Looks like I will start on the panel.

Planning on 50amp with options to run 3 elements, 5 temp probes and 3 pumps.