This may be old hat for you who have your electric breweries up and running, but I am trying to catch up. I would have found this information useful.

I would have found this information useful.

I was curious what the dynamics of heating water in the HLT is like, and I need to find out what happens to the volume of water below the heater element during boil. The latter because I am planning to mount the BK heater several inches above the bottom so to minimize interference with the trube cone forming during whirl pool. If the water below sits undisturbed during the boil I will need to change plans for the BK.

First the location of the components. With 6 gallons of water in the HLT I have 8.25" of water above the recess in the bottom of the keggle. As I drain water, first the float switch trips and drops out the heater contactor at 5.5" water. At 5" the 5500W heater element surfaces, then the PT100 temperature probe at 3" of water. The PT100 is mounted in a sight tube 'T' from Brewhardware.com.

I filled the HLT with 6 gallons of 50°F water. I turn on the PID in manual mode with 100% power. I have a remote temperature probe suspended at the surface of the water.

The surface water starts heating up immediately, but the PT100 is locked at 50°F for 6-8 minutes. At 15 minutes the PT100 reads 60°F and the surface probe is at 180°F. That is a temperature difference of 120°F in only 5.25" of water. Talk about extreme stratification!

The surface temperature keeps rising but at 20 minutes it comes to a stop at 208°F. At this point the PT100 starts increasing in temperature more quickly. The water is not boiling but it is very agitated. I think this stirs up the cold water at the bottom.

At 40 minutes, give or take, the surface and the PT100 comes up to 211°F and I have a boil. At my elevation water boils at about 211.5°. I can maintain a vigorous boil with 60-70% power on the PID. The PT100 fluctuates around 211°F.

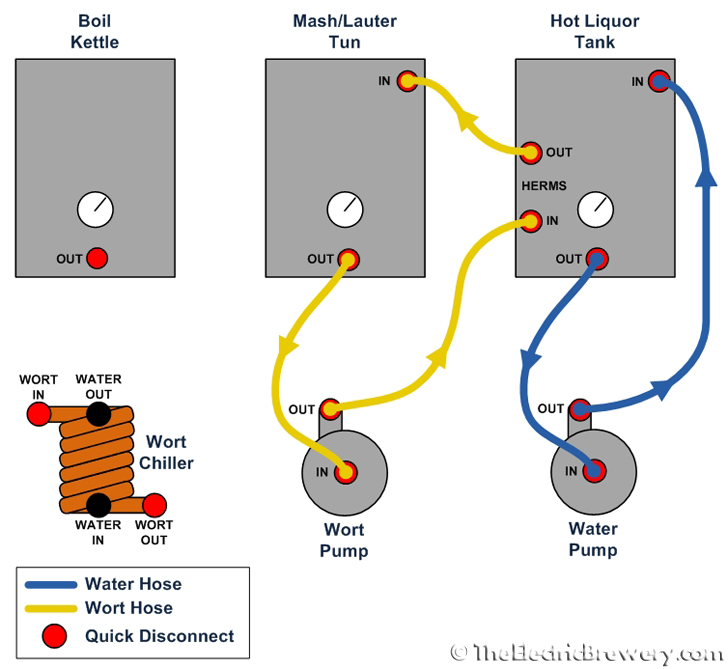

So, one conclusion is I will need to recirculate HLT for heating strike water. I only have one pump so during mash (MLT recirculating) I will need to stir the HLT. It is not so critical because I will accept temperatures between 160-175°F for sparge.

The other conclusion is that it will be fine to mount the BK heater several inches above the bottom, because the boil will agitate the water below the heater.

I hope this information is useful to someone. If you have a different experience please let me know.

I was curious what the dynamics of heating water in the HLT is like, and I need to find out what happens to the volume of water below the heater element during boil. The latter because I am planning to mount the BK heater several inches above the bottom so to minimize interference with the trube cone forming during whirl pool. If the water below sits undisturbed during the boil I will need to change plans for the BK.

First the location of the components. With 6 gallons of water in the HLT I have 8.25" of water above the recess in the bottom of the keggle. As I drain water, first the float switch trips and drops out the heater contactor at 5.5" water. At 5" the 5500W heater element surfaces, then the PT100 temperature probe at 3" of water. The PT100 is mounted in a sight tube 'T' from Brewhardware.com.

I filled the HLT with 6 gallons of 50°F water. I turn on the PID in manual mode with 100% power. I have a remote temperature probe suspended at the surface of the water.

The surface water starts heating up immediately, but the PT100 is locked at 50°F for 6-8 minutes. At 15 minutes the PT100 reads 60°F and the surface probe is at 180°F. That is a temperature difference of 120°F in only 5.25" of water. Talk about extreme stratification!

The surface temperature keeps rising but at 20 minutes it comes to a stop at 208°F. At this point the PT100 starts increasing in temperature more quickly. The water is not boiling but it is very agitated. I think this stirs up the cold water at the bottom.

At 40 minutes, give or take, the surface and the PT100 comes up to 211°F and I have a boil. At my elevation water boils at about 211.5°. I can maintain a vigorous boil with 60-70% power on the PID. The PT100 fluctuates around 211°F.

So, one conclusion is I will need to recirculate HLT for heating strike water. I only have one pump so during mash (MLT recirculating) I will need to stir the HLT. It is not so critical because I will accept temperatures between 160-175°F for sparge.

The other conclusion is that it will be fine to mount the BK heater several inches above the bottom, because the boil will agitate the water below the heater.

I hope this information is useful to someone. If you have a different experience please let me know.