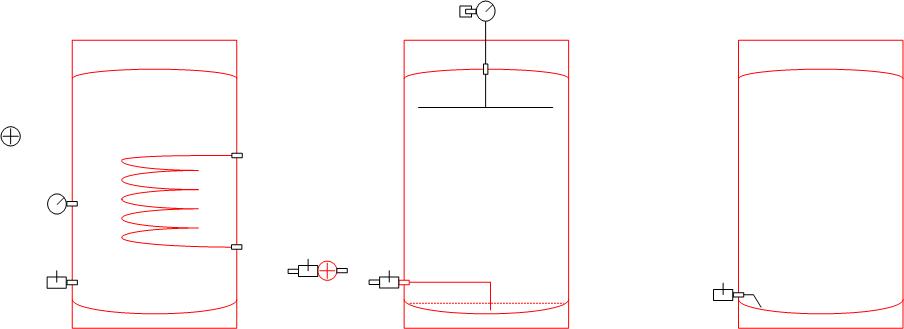

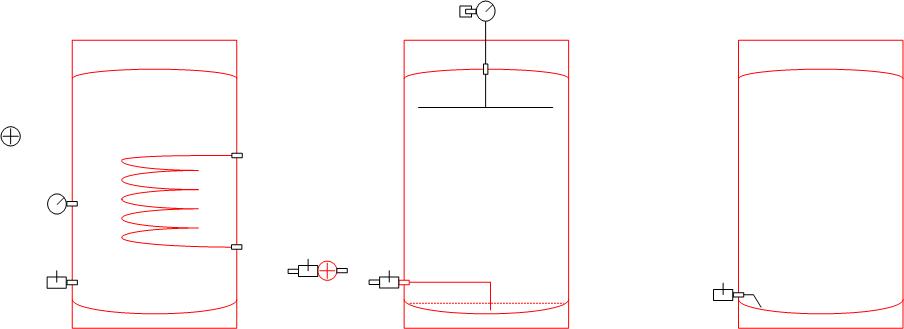

I am working on building a HERMS Keggle brewery. In the end I plan on getting to the point where it will be an electric brewery. In the mean time I would like to move from extract brewing over to all grain to build experience and work out the bugs as I move to electric. For now I have turkey burners that I plan on using.

Currently I have the following equipment.

3 Kegs with tops cut off

Weldless dip tube and false bottom for the MT

1 March 815-PL pump

The items I have are in red.

So I am planning or ordering a bunch of the fittings of Bargain Fittings.

For a second pump I am thinking of picking up a cheap solar pump from eBay. It will just be used to recirculate the water in the HLT to keep even temps.

For the thermometer I am thinking about the Blichmann but not sure if is worth the extra money being eventually I will be going digital with the electric setup run on PIDs.

So here are my questions as I am trying to order as much as I can to save on shipping but trying to keep this order around $300 focusing on the most important without wasting money on items really not needed in the end result.

Thermometers - I have one in my HLT as well as one on the return to the MT. Should I also have one in the MT or can I assume temps entering will be close to internal temps? Any need to have one in the BK? With Extract it is needed for steeping but I will be doing AG so I don't see the need to have it here other than cooling before transferring it to the fermenter. I do have thermometers that I could use for instant read.

SS Cam Lock Disconnects - I like the idea of them maybe I am better off keeping them for an upgrade later and just use barb connectors (Brass ok?) for now. This way I can keep the focusing on the more useful things.

Sparge Arm - Planning on making one of these: http://forums.morebeer.com/viewtopic.php?f=15&p=382337#p382159

I have the tops from the kegs that I made into lids by riveting SS washer on the edge. I will pass the Sparge Arm through the opening in the middle and use a collar to adjust height above grain bed. For 5 gallon batches how long of a vertical pipe should I go with? I will go wit a T on top of this with the thermometer.

HLT Return - just planning on dropping it on top of the water but maybe whip up something like the Sparge Arm for this as well or do another bulkhead with whirlpool fitting.

Sight Glass - If I divert funds from the QD fittings, I could fund sight glass. Which kettles are most valuable to have them in. I guess I could use a paddle with index marks to do a dip reading.

I know, lots of questions. I haven't done an All Grain brew yet and I am sure I will learn a lot and want to make changes as I gain experience. I am pretty close to making the first step though and just wanted to bounce a few things off some people to see if I am really messing up in any area.

Thanks

Currently I have the following equipment.

3 Kegs with tops cut off

Weldless dip tube and false bottom for the MT

1 March 815-PL pump

The items I have are in red.

So I am planning or ordering a bunch of the fittings of Bargain Fittings.

For a second pump I am thinking of picking up a cheap solar pump from eBay. It will just be used to recirculate the water in the HLT to keep even temps.

For the thermometer I am thinking about the Blichmann but not sure if is worth the extra money being eventually I will be going digital with the electric setup run on PIDs.

So here are my questions as I am trying to order as much as I can to save on shipping but trying to keep this order around $300 focusing on the most important without wasting money on items really not needed in the end result.

Thermometers - I have one in my HLT as well as one on the return to the MT. Should I also have one in the MT or can I assume temps entering will be close to internal temps? Any need to have one in the BK? With Extract it is needed for steeping but I will be doing AG so I don't see the need to have it here other than cooling before transferring it to the fermenter. I do have thermometers that I could use for instant read.

SS Cam Lock Disconnects - I like the idea of them maybe I am better off keeping them for an upgrade later and just use barb connectors (Brass ok?) for now. This way I can keep the focusing on the more useful things.

Sparge Arm - Planning on making one of these: http://forums.morebeer.com/viewtopic.php?f=15&p=382337#p382159

I have the tops from the kegs that I made into lids by riveting SS washer on the edge. I will pass the Sparge Arm through the opening in the middle and use a collar to adjust height above grain bed. For 5 gallon batches how long of a vertical pipe should I go with? I will go wit a T on top of this with the thermometer.

HLT Return - just planning on dropping it on top of the water but maybe whip up something like the Sparge Arm for this as well or do another bulkhead with whirlpool fitting.

Sight Glass - If I divert funds from the QD fittings, I could fund sight glass. Which kettles are most valuable to have them in. I guess I could use a paddle with index marks to do a dip reading.

I know, lots of questions. I haven't done an All Grain brew yet and I am sure I will learn a lot and want to make changes as I gain experience. I am pretty close to making the first step though and just wanted to bounce a few things off some people to see if I am really messing up in any area.

Thanks