BigEasy43

Well-Known Member

- Joined

- Jan 18, 2016

- Messages

- 81

- Reaction score

- 7

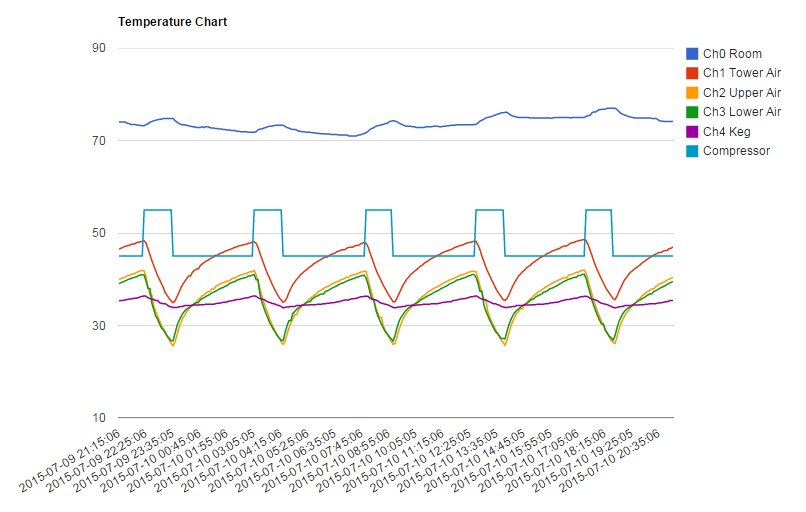

So this is the first time I have kegged my beer and just want to make sure I am doing things right with my keezer. So I am using an ink-bird 308 and have the prob hanging in the air about 8 inches from the bottom. I have my temp set at 40f with a 5 degree upper and lower setting and noticed my freezer kicks in every 36mins to cool and wondering if there is anything I can do to make the temp somewhat stable. I have read about the prob in water, tape it to the keg or the side of freezer. Should I be concerned that my compressor on my freezer is kicking in every 36mins? Any advice would be great. Thanks