ttuato

Well-Known Member

I need some advise from you the pros. I am in the midst of designing a new eBIAB brewing platform.

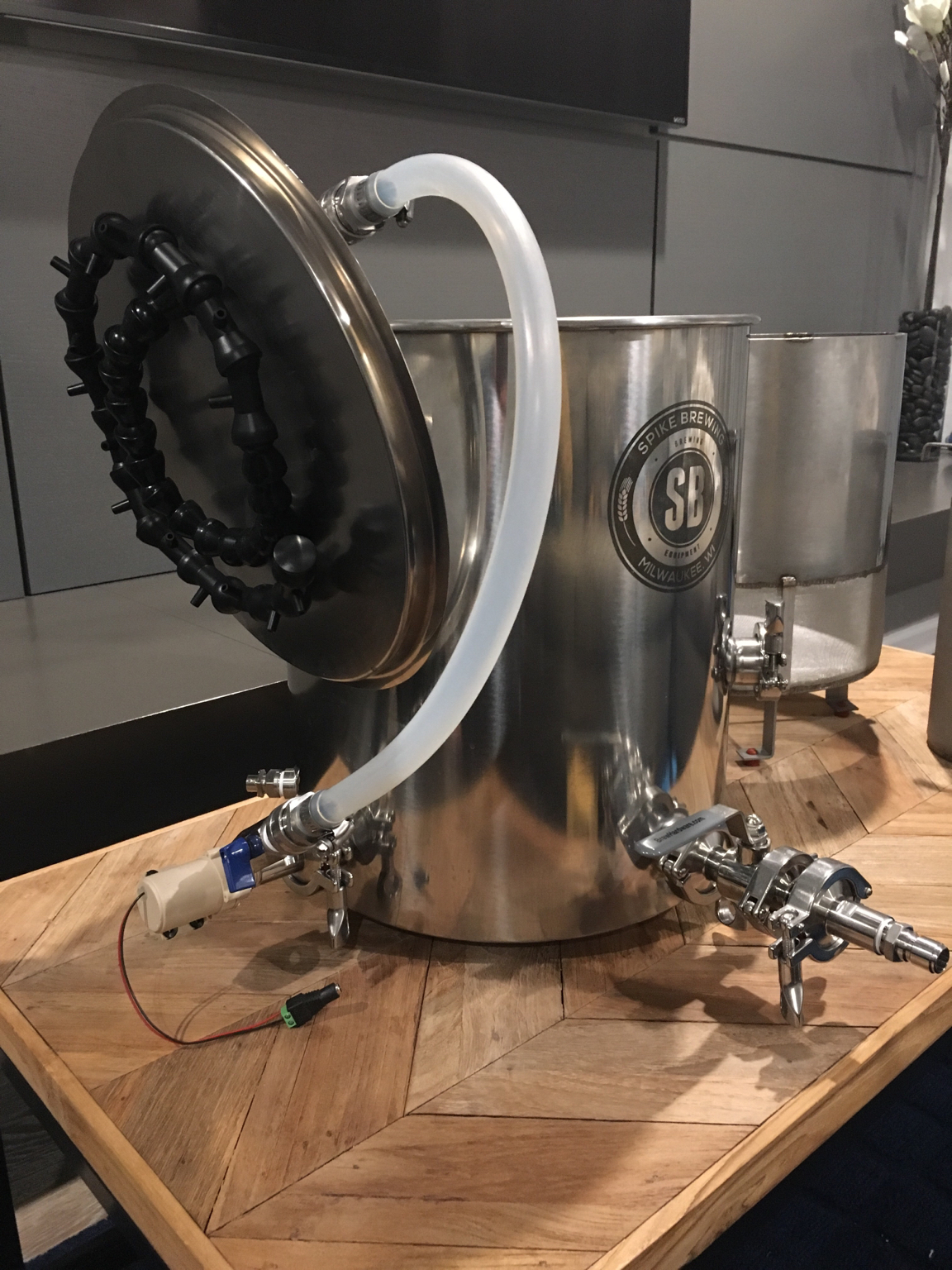

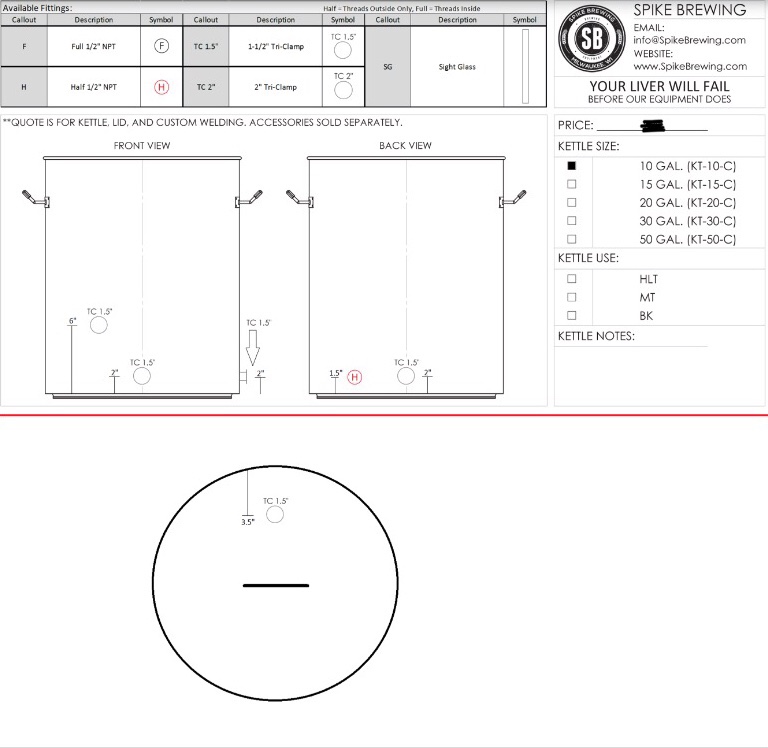

- Spike 15gal brew kettle - 90% of time it will be full volume mash for 5gal batch w/ recirculation. Occasionally I will do a 10gal batch and sparge. All 1.5" triclover ports. Brew Boss controller w/ 5500w element.

- The first option is to have separate ports - whirlpool port located ~6" from the bottom and a recirculation port 2" from the top - swap hoses from pump as necessary during the brewing process

- The second option is to have a single port 2" from the top and then sway attachments for recirculation / whirlpool at the appropriate time during the brewing process

Since I am already set on the cold side with Norcal pimped Speidel fermenters and dedicated fermenting temp controlled mini-fridges, I want to spend my money on some bling.

Since I am already set on the cold side with Norcal pimped Speidel fermenters and dedicated fermenting temp controlled mini-fridges, I want to spend my money on some bling.