Well, here's my update on the progress of my all grain brew setup.

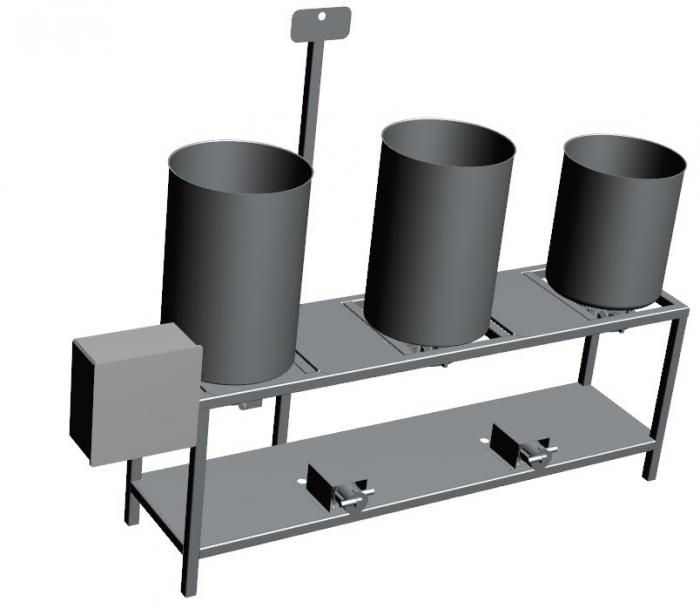

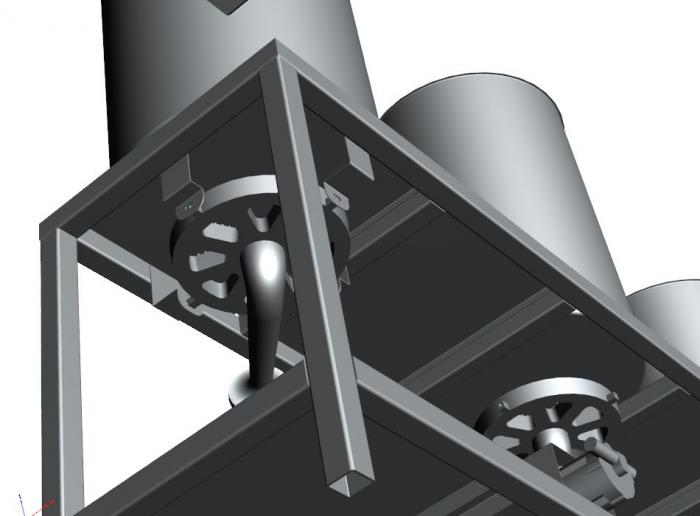

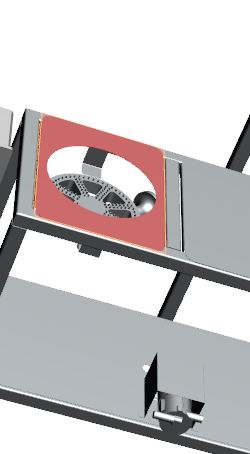

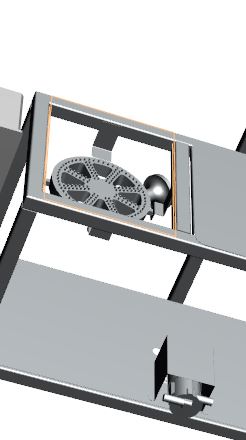

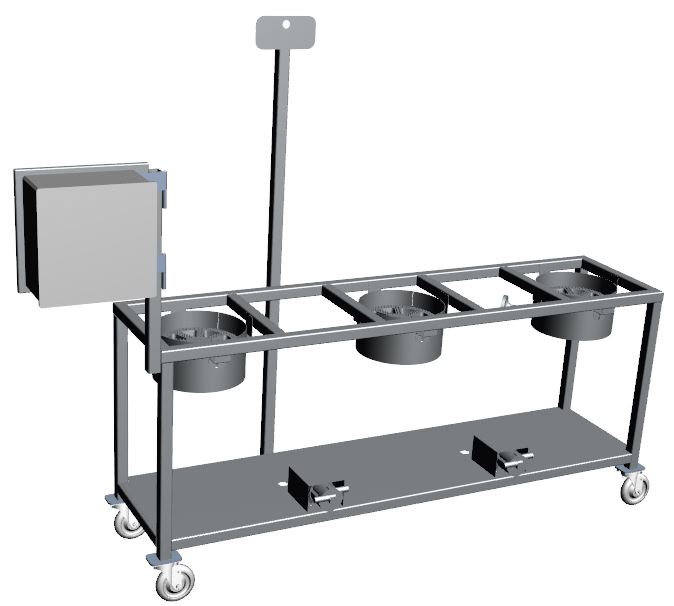

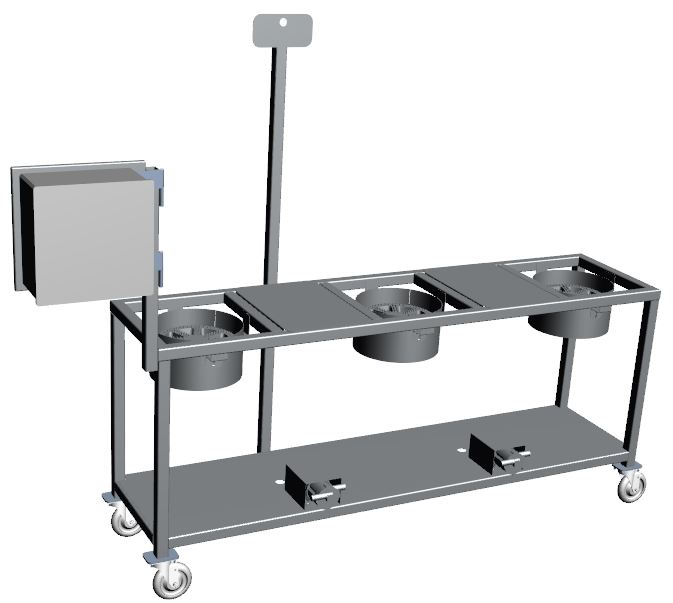

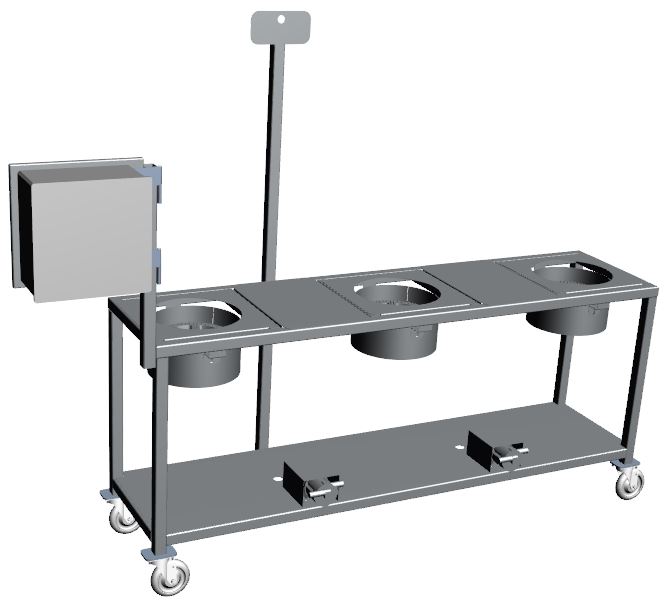

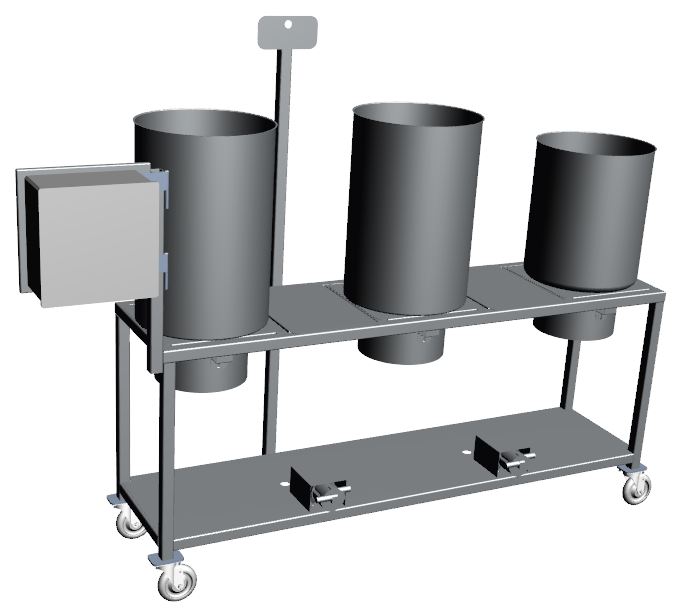

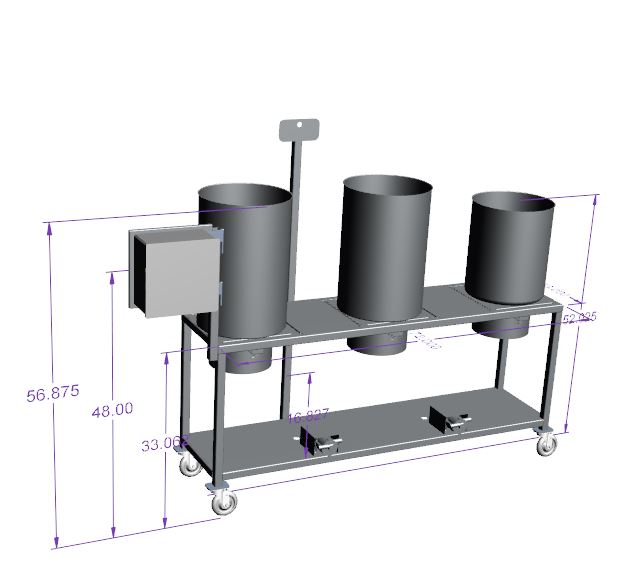

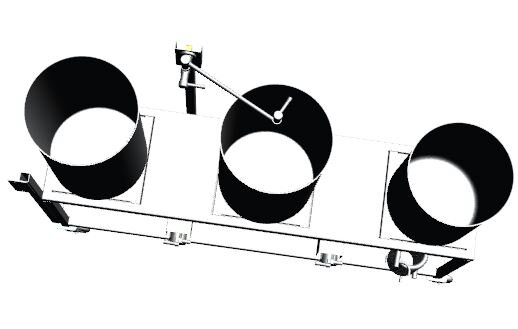

I'm going with a typical horizontal brew stand that will accommodate a Hot Liquor Tank and a Mash Tun (both are 15.5 gallon keggles), as well as a 15 gallon Blichmann BoilerMaker Brew Kettle (15 gallons, too). My brew buddy is a Mechanical Engineer and he specializes in stainless steel (perfect!). He and I just finished the design and the stand will be welded in early January. The brew stand will also have two chuggar pumps (I have one at the moment, but I still need to buy one more).

For the HLT, I went with a HERMS setup. I also added a 2000 watt element with a weldless fitting to heat the water (this is controlled by a Johnson A419 temperature controller that is mounted in a custom built control box). The thermometer probe from the A419 temperature controller is placed in a 4 inch thermowell on the side of the HLT. All the valves, fittings, thermowell, Cam and Groove fittings came from Bobby at

www.brewhardware.com. I went with 3 piece stainless steel valves and 1/2 inch ID dip tubes. The stainless steel coil for the HERMS came from stainlessbrewing.com (great price and excellent workmanship). I put together some cam/groove fittings, a stainless steel tee and CDN digital thermometers to connect to the in and out ports of the herms coil so that I can accurately measure the wort temp going into and out of the HLT. I also added a sight glass with incorporated tee and thermometer.

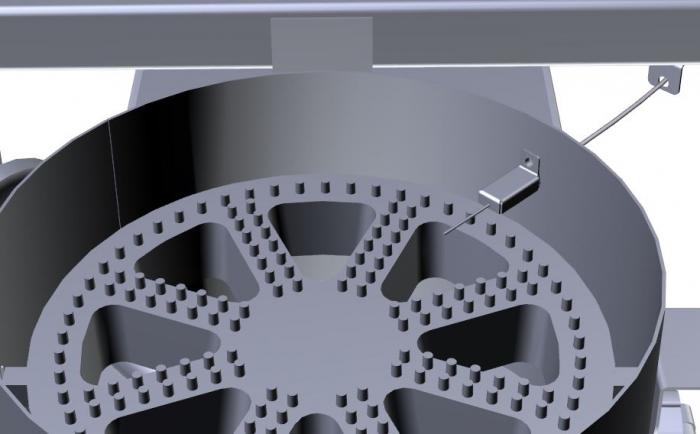

For the Mash Tun, I again went to Bobby’s site, brewhardware.com, and purchased a stainless steel false bottom, ½ inch ID dip tube, 3 piece valves, a Mash Recirculation Return Tube, and a sight glass. Because I’m recirculating the wort through the HERMS system, I don’t have to use LP gas on the Mash Tun while I’m mashing.

For the boil kettle, I’m using a 15 gallon Blichmann Boilermaker with sight glass, brewmometer, and whirlpool valve. I also picked up a Hop Spider from

www.stainlessbrewing.com.

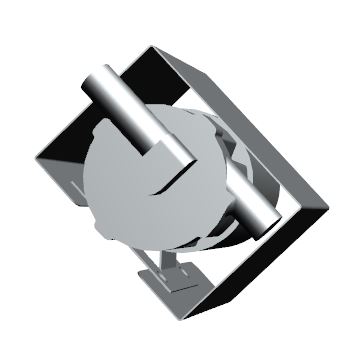

And finally, to chill the boiling wort to a cool 68 degrees, I bought a stainless steel convoluted cross flow chiller from williamsbrewing.com. The chilled wort goes into either of my two 15.5 sanke kegs converted with a Cornelius keg top fermenters. I picked up these beauties off craigslist for $60 a piece. ( I also got a Fail To Obey Traffic Device photo ticket on my way back from picking them up. So I'll need to tack on an extra $260 to the price)...

To date, I've only brewed on the system once. I brewed my first 5 gallon all grain Amber Ale. I’m drinking it as I type this. It turned out well, but some improvement in efficiency is needed.

). I'm not going for a ghetto look either - no offense.

). I'm not going for a ghetto look either - no offense.