planker101

Well-Known Member

I literally spent the last 5 hours searching the internet and this site to tey and figure this out, but clearly I don't even know enough to know what to search for.

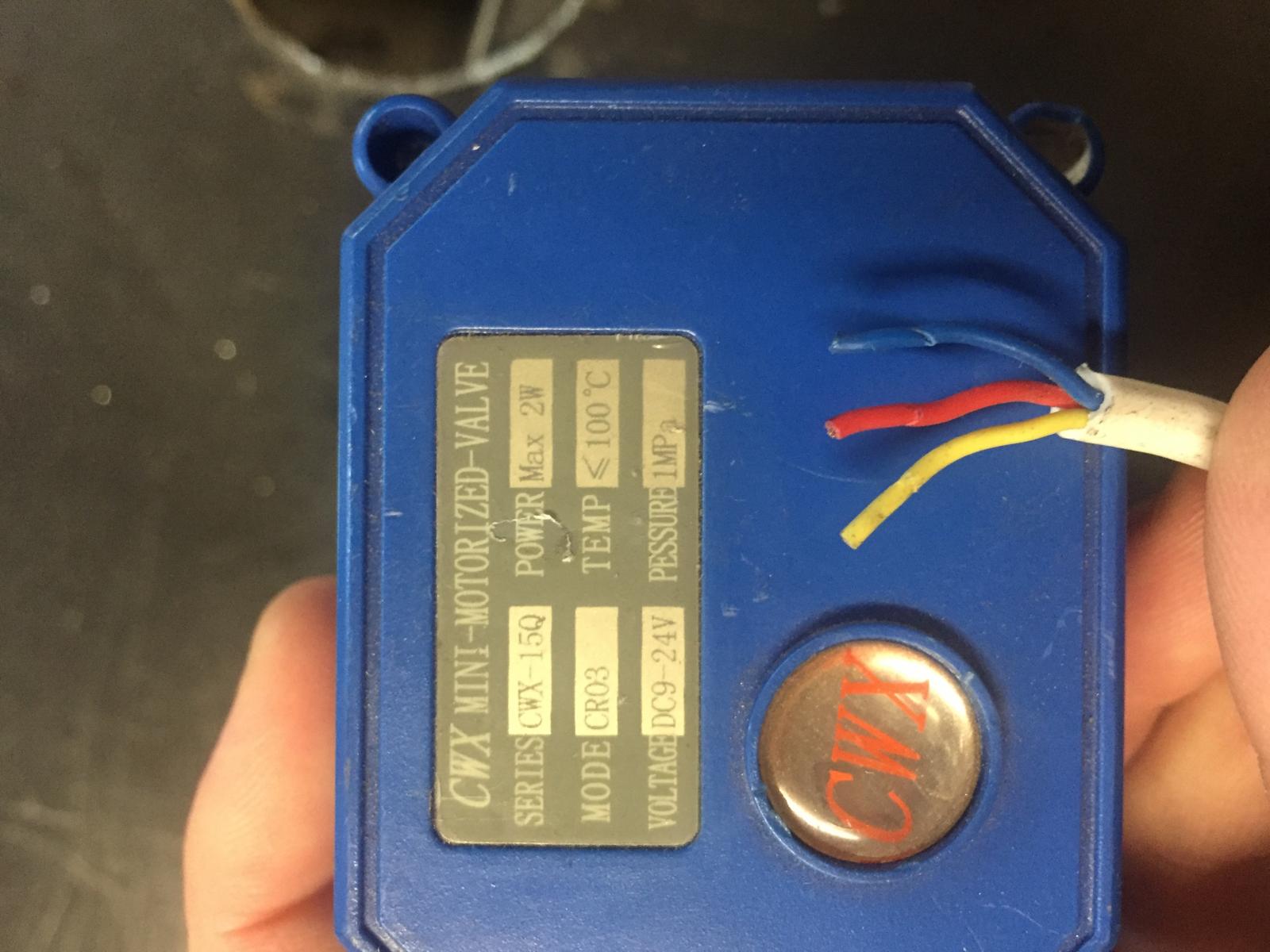

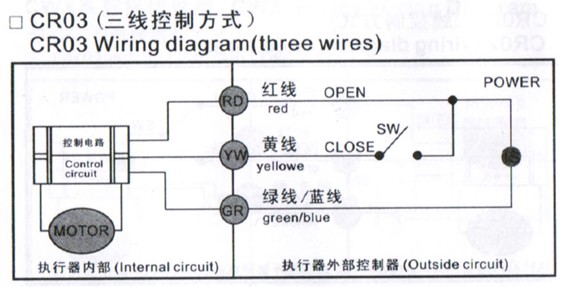

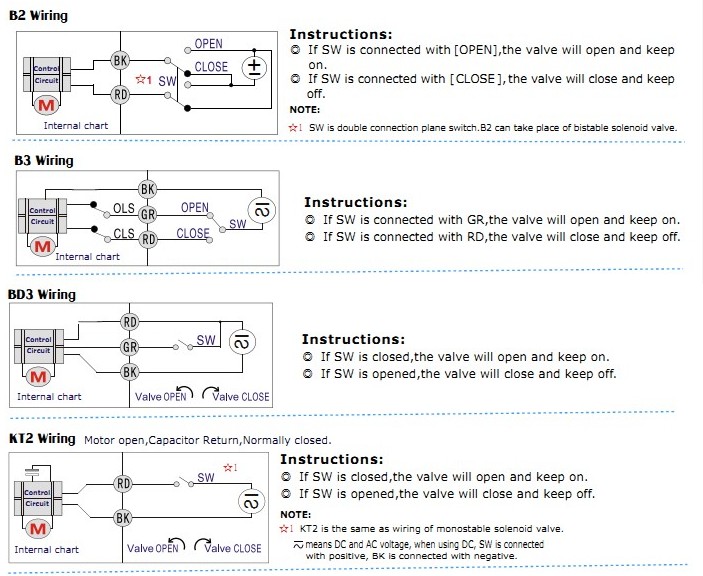

I got a bunch of motorized ball valves in a lot of brew fittings and would like to incorporate them into my system. Unfortunately I have zero experience going from AC to DC power. (I have done plenty of wiring in my house, but that is pretty straight forward).

If someone is willing to give me a walk through from my house outlet to the ball valve I would be extremly appreciative! I would like to build a control box that will allow me to control up to 8 ball valves. Two of them are three way. the are listed as being DC. I would like to control them manually.

If you need more info let me know.

Thanks!

I got a bunch of motorized ball valves in a lot of brew fittings and would like to incorporate them into my system. Unfortunately I have zero experience going from AC to DC power. (I have done plenty of wiring in my house, but that is pretty straight forward).

If someone is willing to give me a walk through from my house outlet to the ball valve I would be extremly appreciative! I would like to build a control box that will allow me to control up to 8 ball valves. Two of them are three way. the are listed as being DC. I would like to control them manually.

If you need more info let me know.

Thanks!