Adrian Gresores

Well-Known Member

- Joined

- Nov 16, 2019

- Messages

- 49

- Reaction score

- 9

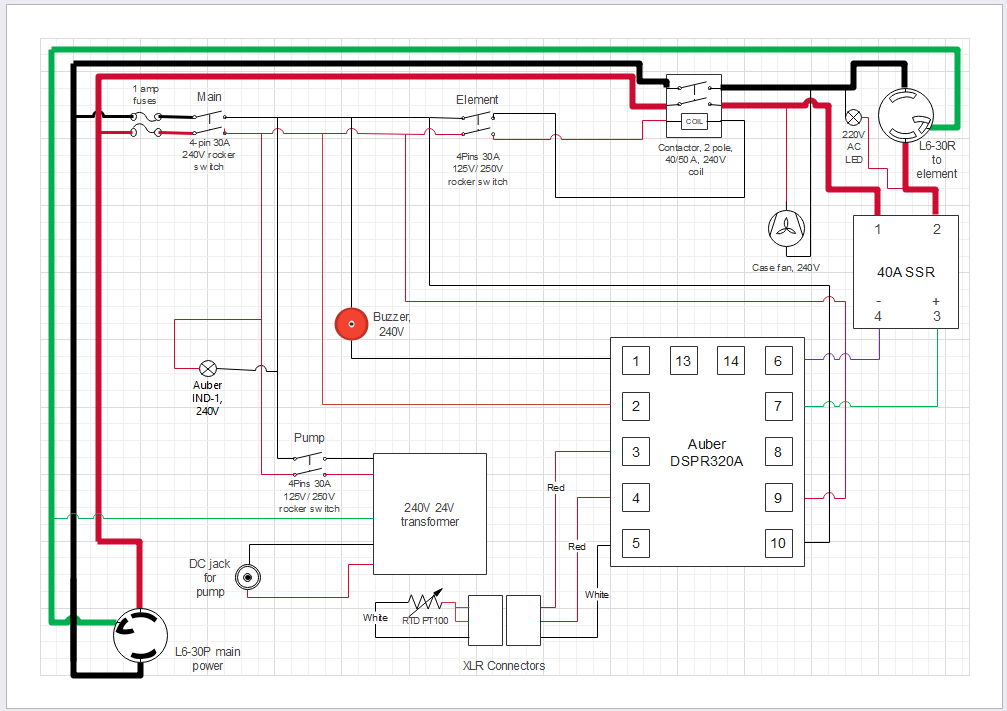

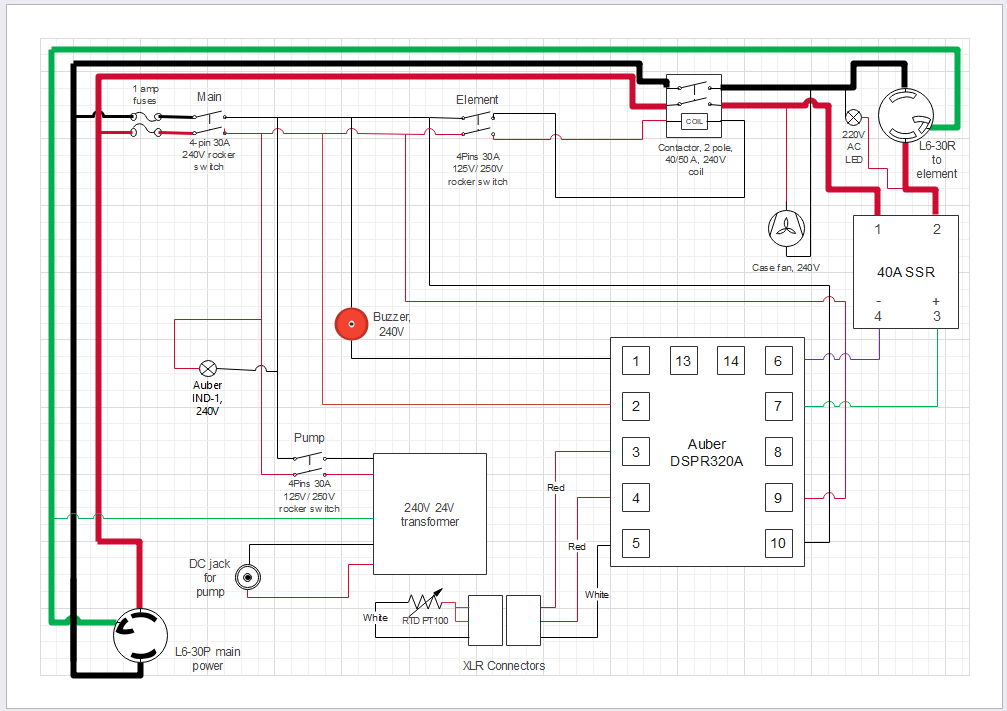

Lately, I have been having a big problem with my controller panel. Specifically, power is being sent to the heating element even before any program is running on the DSRP320A (top line shows current water temperature and lower line shows STOP). For reference, if I only turn on the main power switch, there is a minimal voltage from the controller to the SSR (8 mV), and no voltage from the output terminals on the SSR (1 and 2). Resistance between 3 and 4 shows an open circuit. However, as soon as I flip the element switch on, the element LED turns on and the voltage between SSR terminals 1 and 2 goes to 115V. The LED on the SSR never turns on, though. Again, this is before I begin running any program. I have already replaced the SSR once, with no change. Any idea where the problem lies?