BrewinSoldier

Well-Known Member

- Joined

- Jul 13, 2015

- Messages

- 471

- Reaction score

- 52

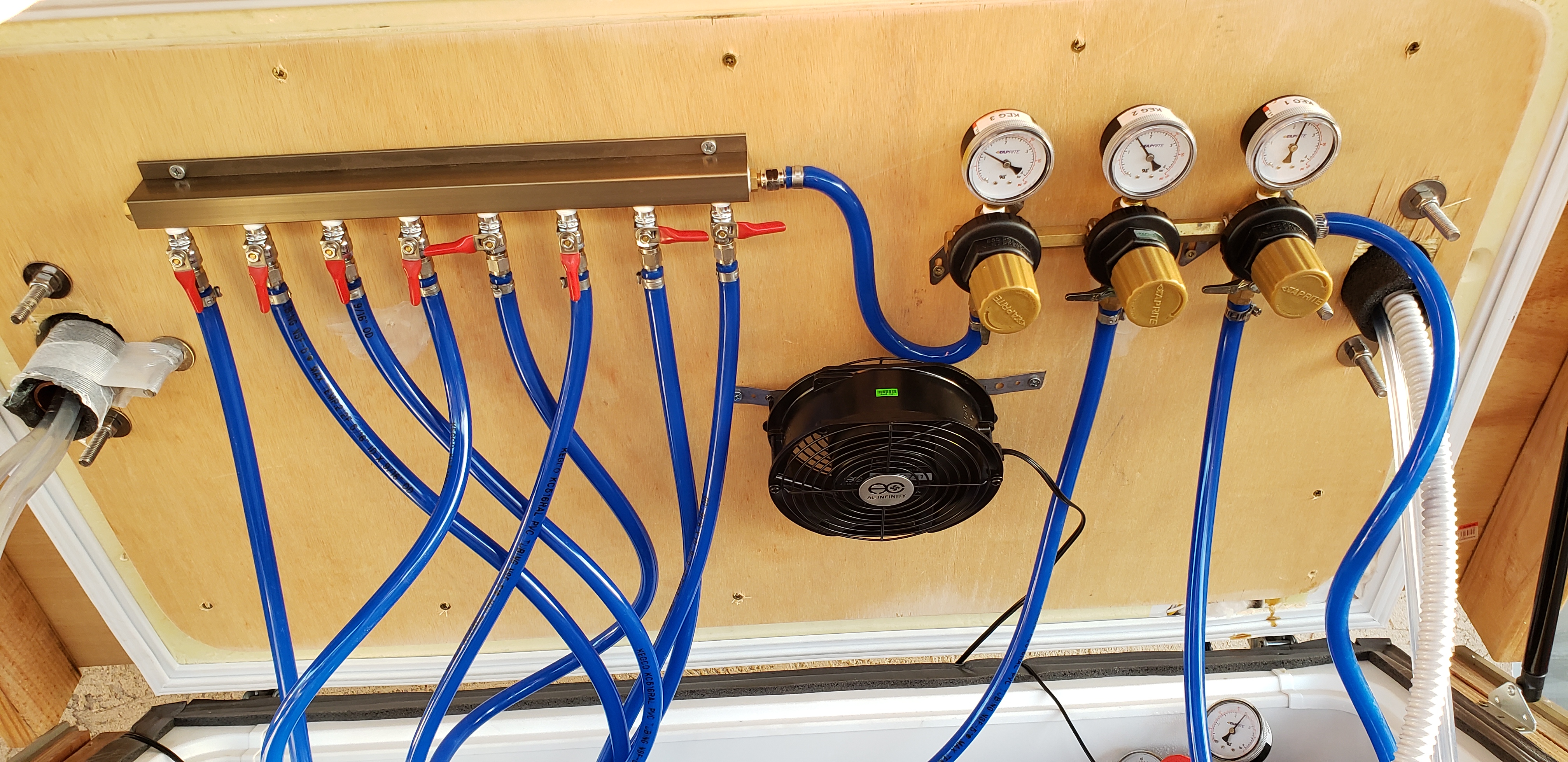

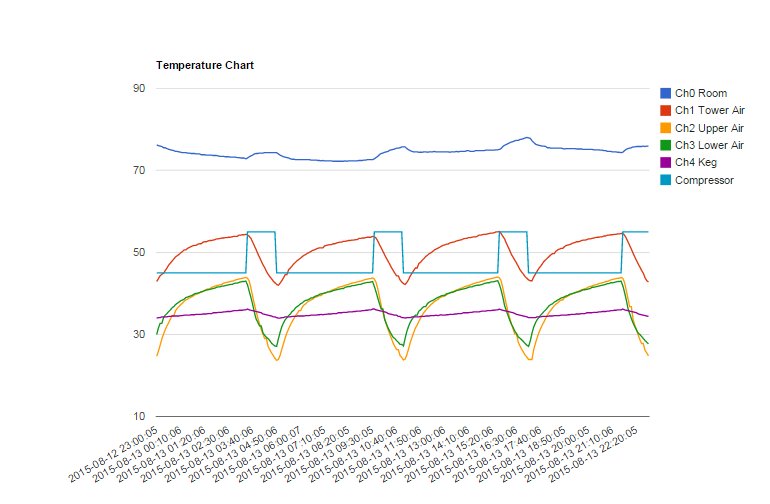

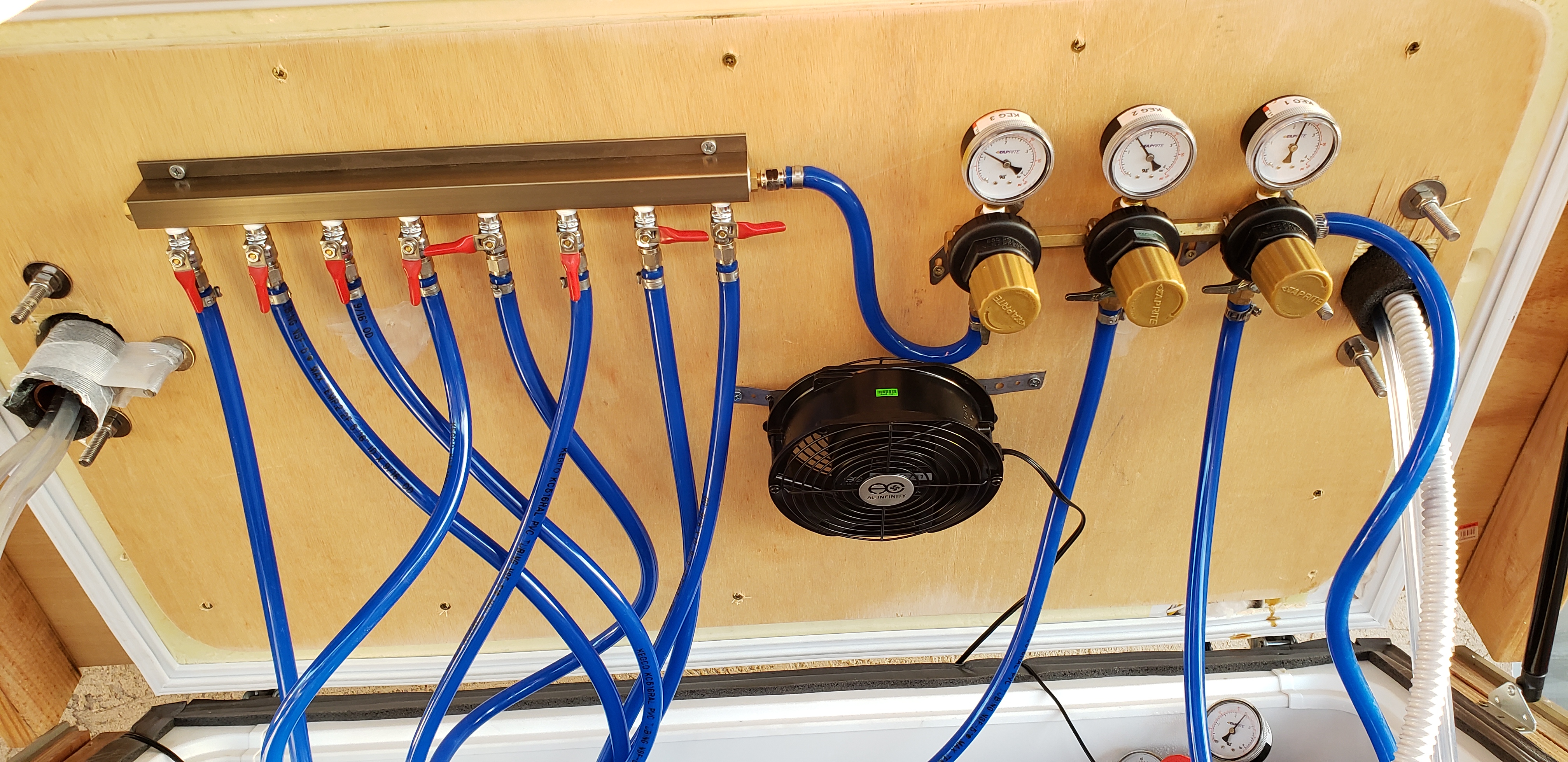

Hey guys and gals! I built a new keezer specifically so I could have more capacity for kegs. I bought a brand new whirlpool 15 cu ft chest freezer and built it into a coffin keezer. I even fabricated a custom tower for it which I'm having cooling problems with as well. I need to play around with some other options on the tower before I get any further. The beer coming out of the taps is just too damn warm, but it could be because of the other issue I'm having with the keezer.

One issue I'm having is the dang water pooling. I never had this in the 7cu ft keezer I built with a collar.

I am getting an excessive amount of water pooling on the bottom of the keezer. I vacuum it up and the next day it's back. I put some of the foam insulation around the bottom keezer size in case there were any leaks coming out. The water today wasn't as bad but still there.

Here is the weird part. I have my controller set to 37°. I have the temp probe submersed in a jar of water on the keezer hump inside. I tested the water temp against the probe with two different thermapens and it's reading accurate. Problem is the beer temp in the keg is way high higher...like 42°. I don't get this??? And that's running straight from the keg a ball lock liquid fitting with a tap attached straight to it, so no beer lines to go through, etc. And I left the taps inside the keezer over night so they would be chilled.

Any advice would be greatly appreciated. I'm going crazy over here.

One issue I'm having is the dang water pooling. I never had this in the 7cu ft keezer I built with a collar.

I am getting an excessive amount of water pooling on the bottom of the keezer. I vacuum it up and the next day it's back. I put some of the foam insulation around the bottom keezer size in case there were any leaks coming out. The water today wasn't as bad but still there.

Here is the weird part. I have my controller set to 37°. I have the temp probe submersed in a jar of water on the keezer hump inside. I tested the water temp against the probe with two different thermapens and it's reading accurate. Problem is the beer temp in the keg is way high higher...like 42°. I don't get this??? And that's running straight from the keg a ball lock liquid fitting with a tap attached straight to it, so no beer lines to go through, etc. And I left the taps inside the keezer over night so they would be chilled.

Any advice would be greatly appreciated. I'm going crazy over here.