I used online calculators to guess your original gravity (based on weight of 3.7 cups sugar in 3 gal volume) is around 1.065. If you get to 1.040 you'll be around 3.25%, or 1.035 for about 4%.

Unfortunately fridging just puts yeast to sleep, which is only OK if you're going to keep the bottles in the fridge all the time until you want to drink them. Killing them with alcohol would take a total alcohol concentration well over 10% (depending on strain), and then you'd have carbonation problems.

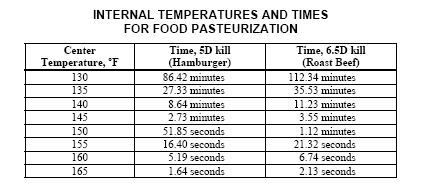

Your best best is to bottle while the yeast is active, then (if you're bottling in glass) also bottle a small plastic soda bottle at the same time, to use for comparison. When that test bottle gets very firm, like a carbonated soda (probably somewhere 12-36 hours, depending), you put all the bottles in a 160-170F water bath to pasteurize them. Let them sit until you think the liquid inside the bottles has reached that temperature, maybe 20-30 minutes. They will not explode from this, and it will kill the yeast for good, and your bottles will be carbonated.

It sounds kind of "mad scientist", but people do this with sweet ciders and other specialty beers all the time. If you don't have a pot big enough for all your bottles on the stove at once, you can rotate them out. I think 20-30 minutes is more than enough to get them up to temp.

Just a warning, though--if you don't pasteurize successfully, or if you wait too long, you will get exploding bottles! Which is very unpleasant.

So it's better to be slightly too thorough than not enough. 20 minutes in 170F water really should be plenty. I'm not an expert in this technique, though, so if you want you can also consult people on the cider and soda making forums, they do this a lot.