Spinout

Well-Known Member

I'd like to stop propane cooker brewing and go electric. But...the more I read on here, the more I realize I know nothing. Getting a heating element installed into my keggle is straightforward enough, but it's all the stuff between it and the wall outlet that losses me. Are there systems a guy can buy, plug it into the wall and plug your heating element into it.....and that's about it?

I read a little about the brew boss, seems fairly simple....what about others?

Right now I'm using a keggle, 30qt HLT, and 5 gallon cooler/MLT. I wouldn't complain about going to biab but also wouldn't mind having a Herms /rims system either. I also have a 50amp receptacle in the shop for power. What systems should I be looking at?

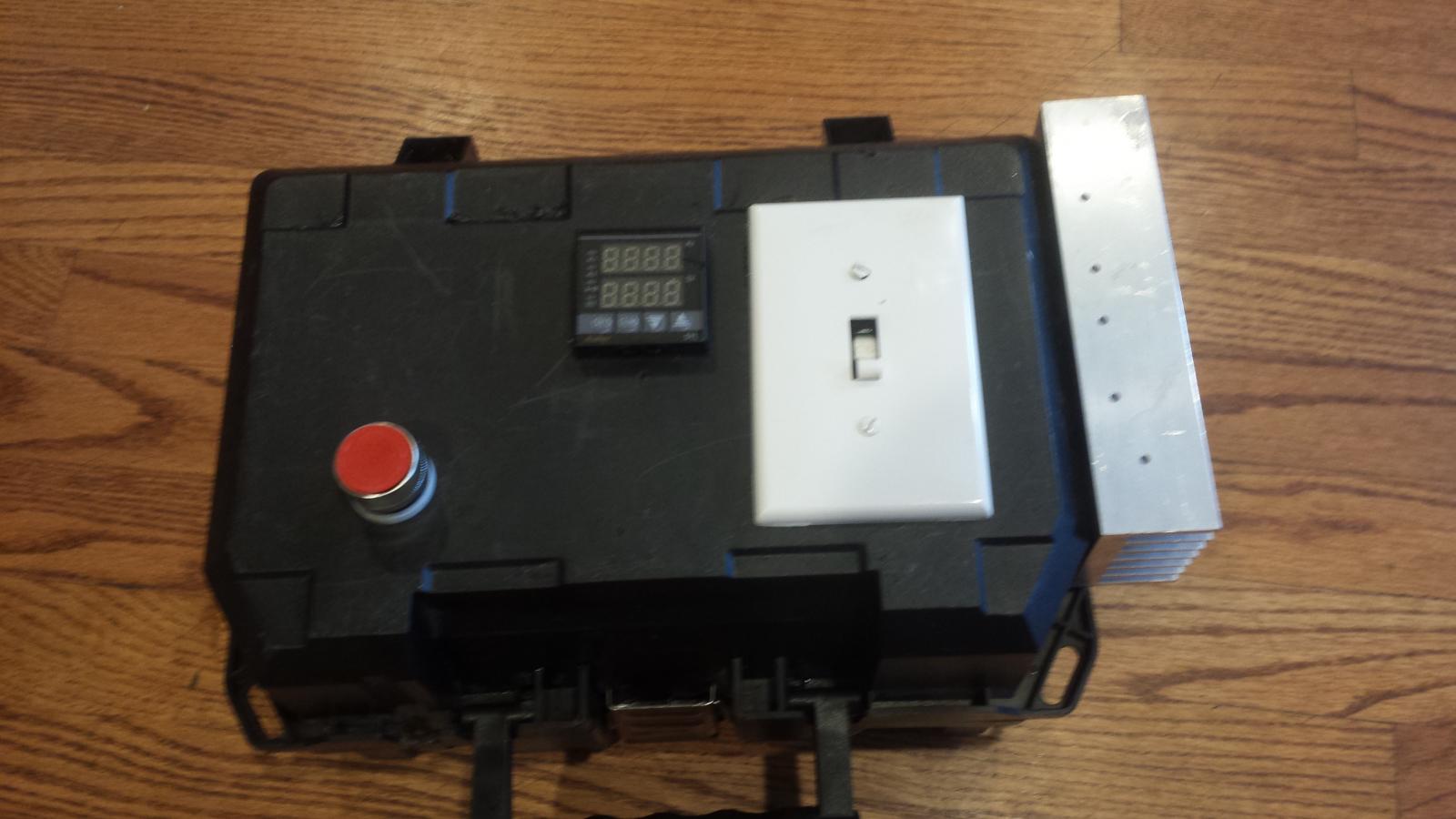

Iknow it seems like a very broad question, but all the threads about control panel builds makes me just want to buy a Pre assembled kit that just needs plugged into the wall.

I read a little about the brew boss, seems fairly simple....what about others?

Right now I'm using a keggle, 30qt HLT, and 5 gallon cooler/MLT. I wouldn't complain about going to biab but also wouldn't mind having a Herms /rims system either. I also have a 50amp receptacle in the shop for power. What systems should I be looking at?

Iknow it seems like a very broad question, but all the threads about control panel builds makes me just want to buy a Pre assembled kit that just needs plugged into the wall.