Hello,

This thread will be where I chronicle my first few batches as I set up my kitchen brewery.

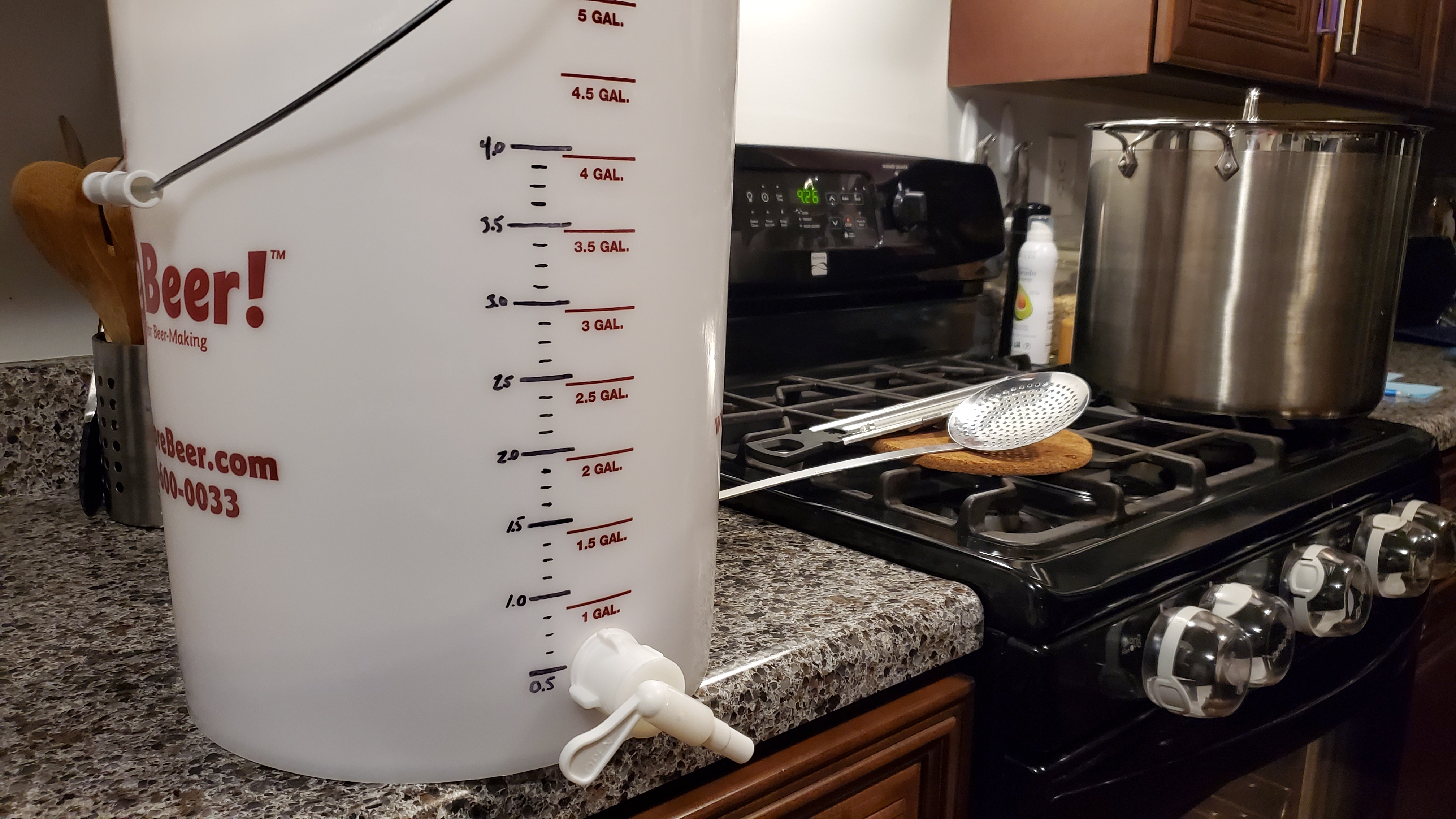

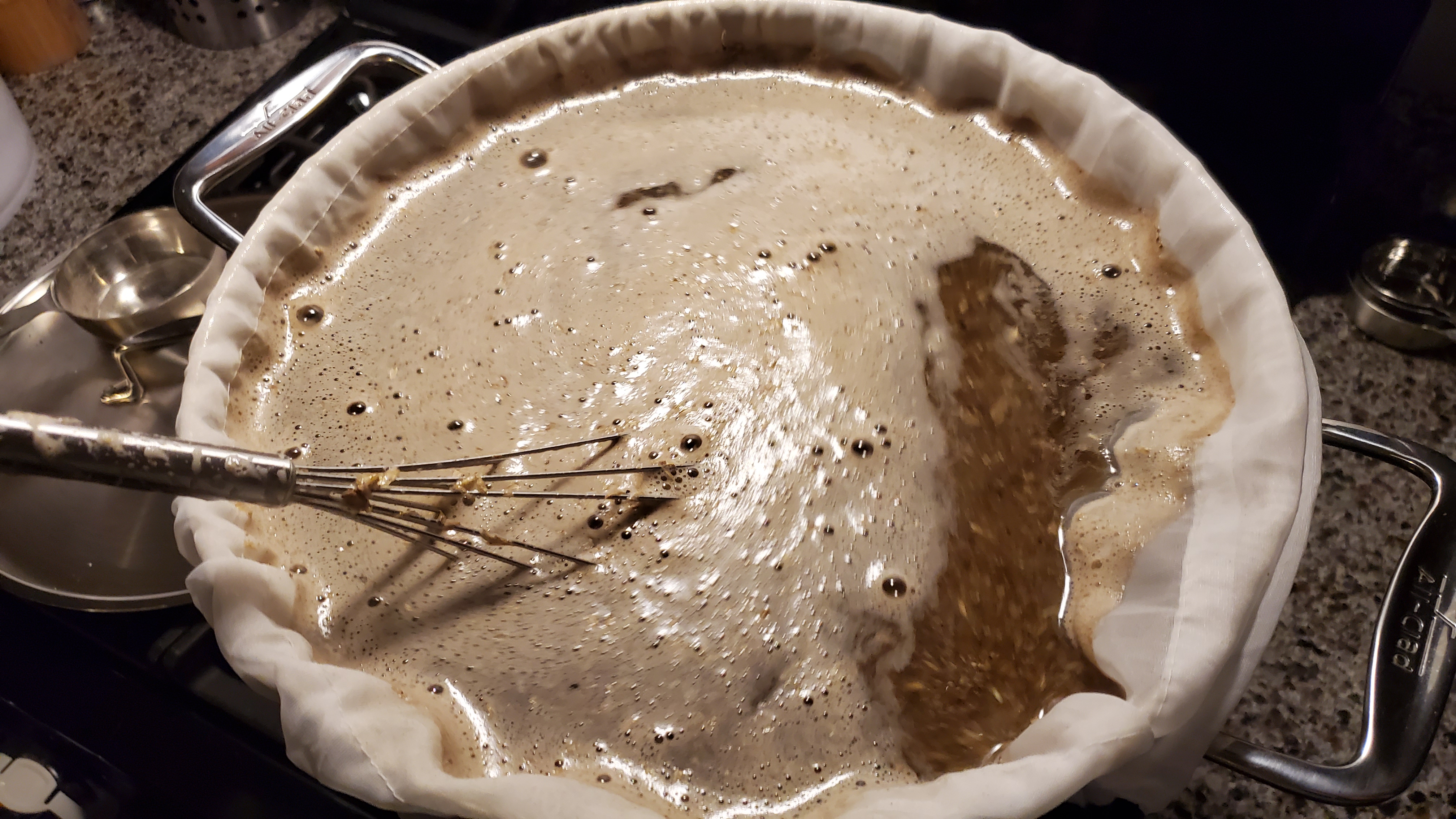

I've made a handful of 5G batches of extract with steeped grains in my brother-in-law's garage and helped him with his first few all-grains in a cooler mash tun. For my setup, I am planning to brew 2-3G batches on my kitchen stove. BIAB, single dunk sparge, full-volume boil.

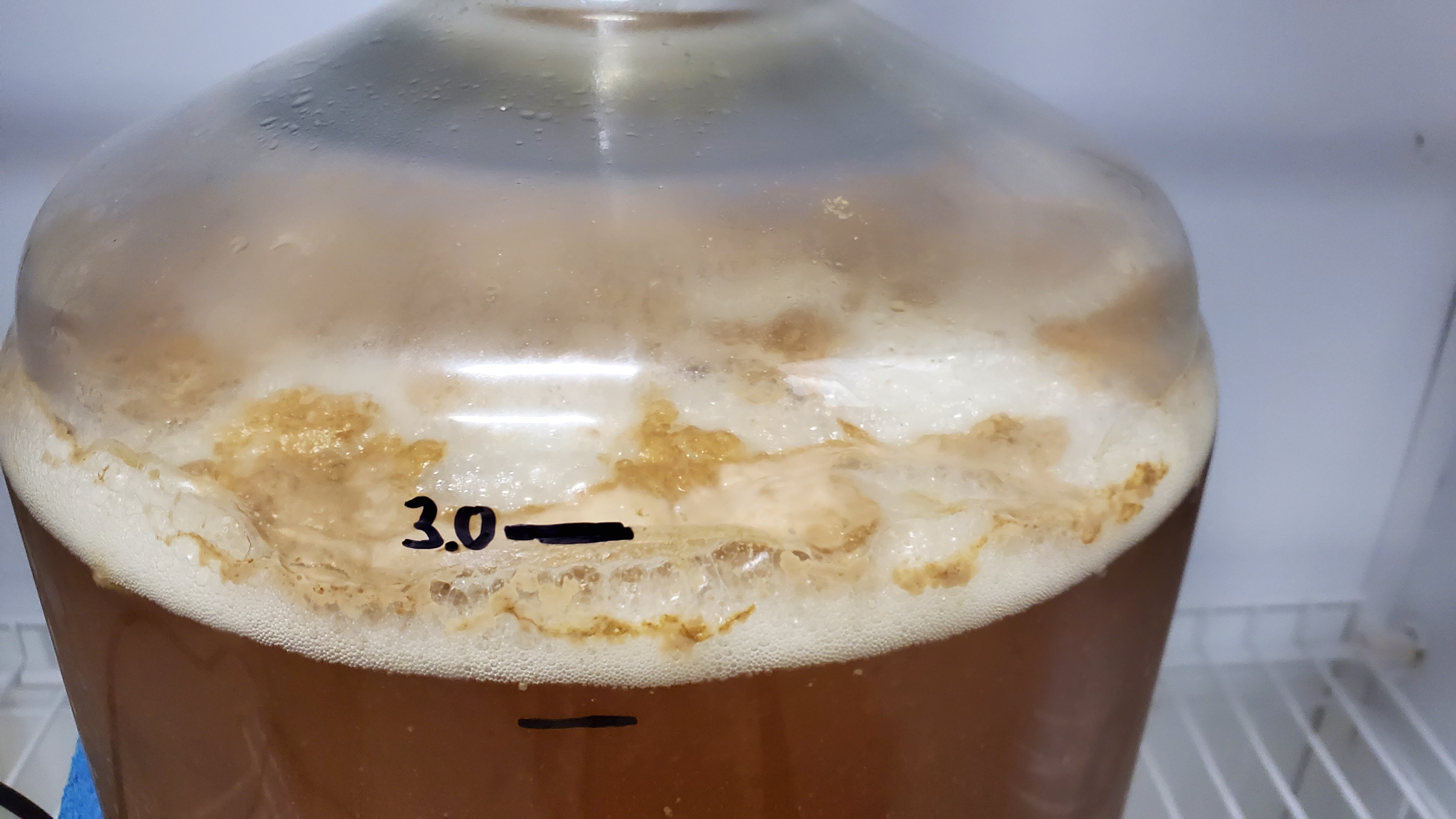

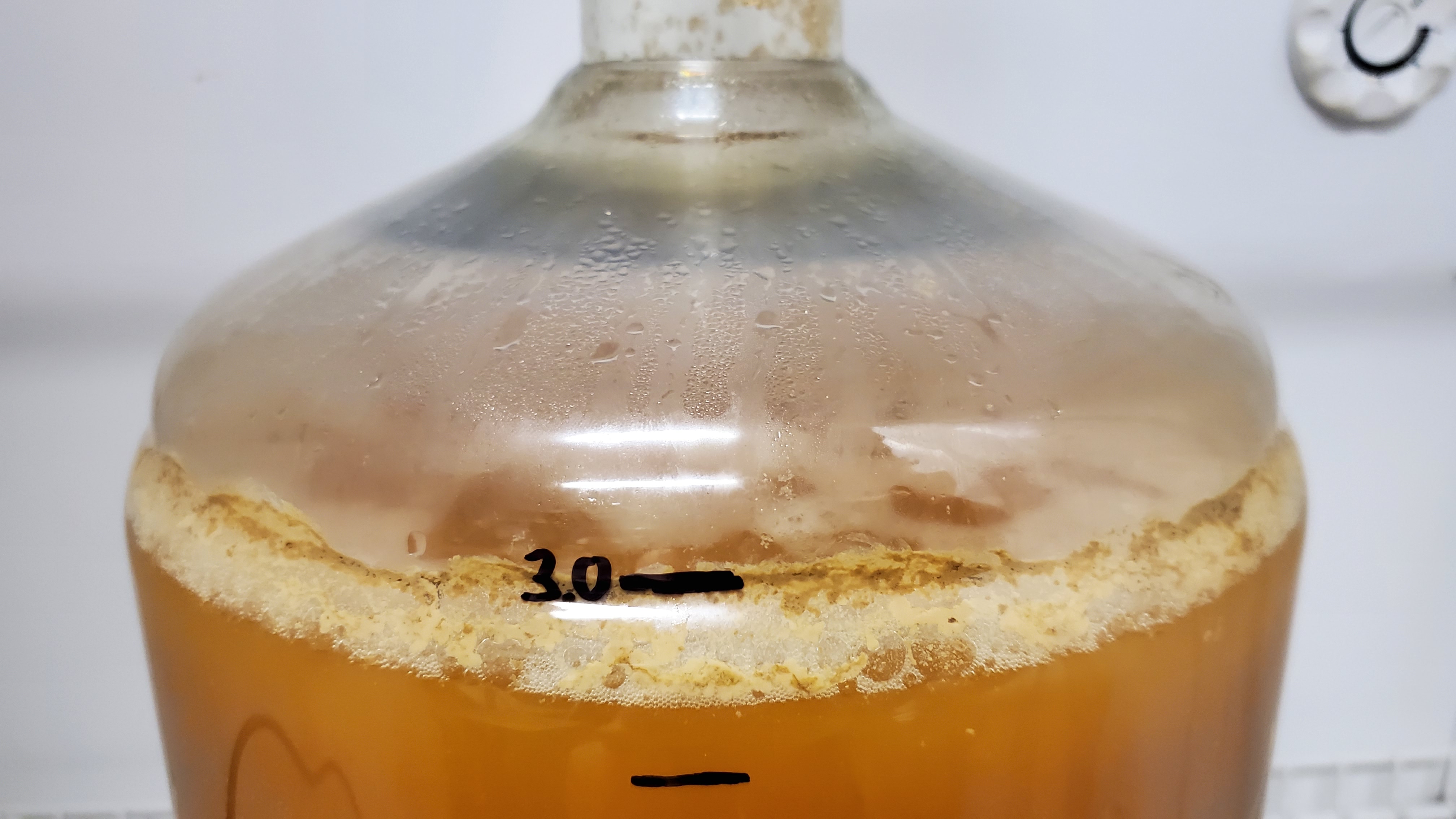

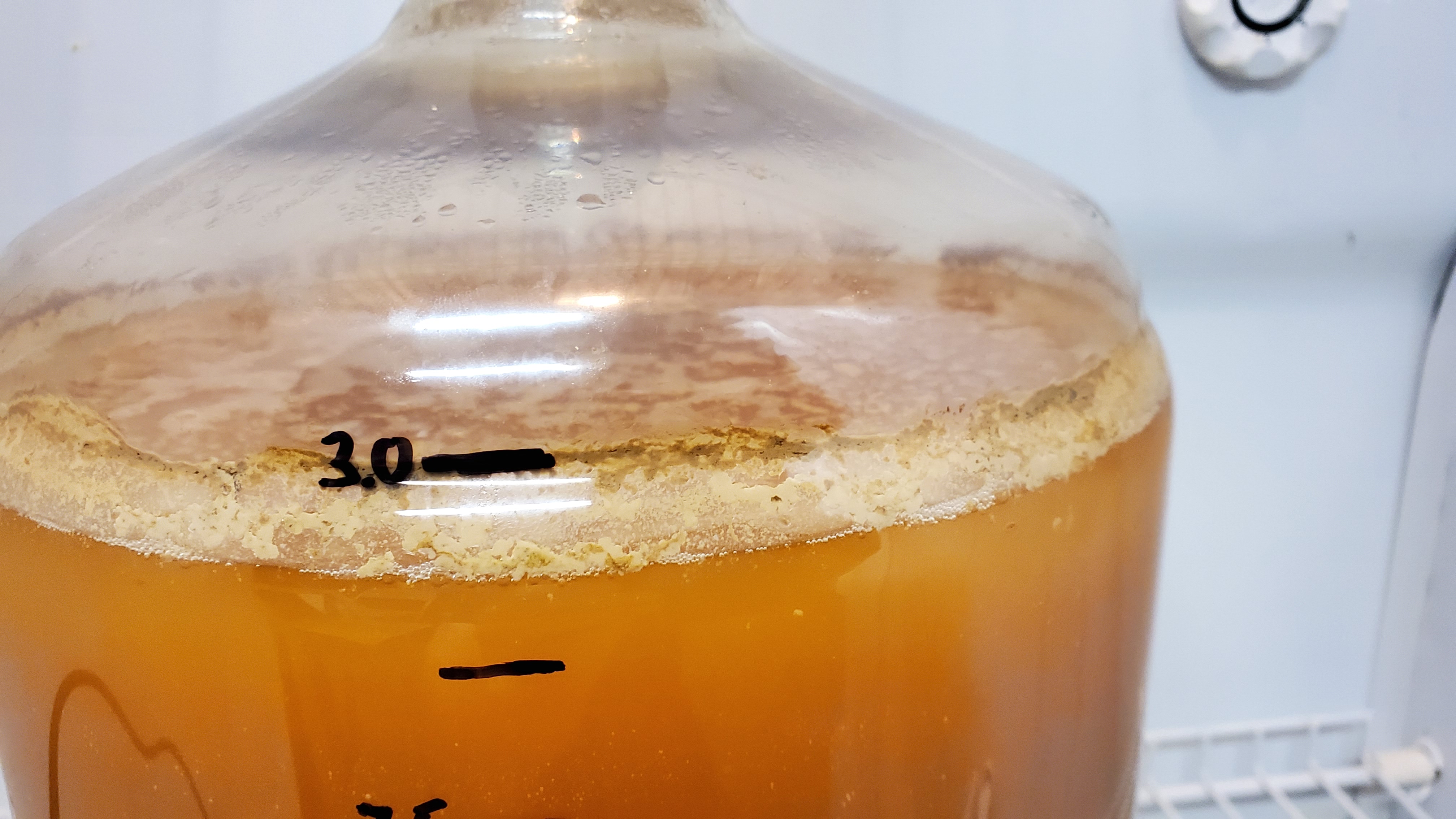

The first two batches will be very similar recipes with extract and steeped grains. The ingredients were intended for a 5g batch, I'm splitting it into two 2.5G batches. The original 5G recipe had a jug each of pilsner and Munich LME. The first 2.5G batch will use the pils, the second the Munich. Steeping grains, yeast, and hops type will be the same in each batch. Original recipe based on the Belgian Pale Ale in the "Make Your Best" series by Josh Weikert.

The third and fourth batches will be very similar to each other as well, the Pale and Dark Milds also of the "Make Your Best" series.

The main goals for these first four batches are to become familiar with my equipment and process, collect brewhouse data, and dial in brewing software.

This thread will be where I chronicle my first few batches as I set up my kitchen brewery.

I've made a handful of 5G batches of extract with steeped grains in my brother-in-law's garage and helped him with his first few all-grains in a cooler mash tun. For my setup, I am planning to brew 2-3G batches on my kitchen stove. BIAB, single dunk sparge, full-volume boil.

The first two batches will be very similar recipes with extract and steeped grains. The ingredients were intended for a 5g batch, I'm splitting it into two 2.5G batches. The original 5G recipe had a jug each of pilsner and Munich LME. The first 2.5G batch will use the pils, the second the Munich. Steeping grains, yeast, and hops type will be the same in each batch. Original recipe based on the Belgian Pale Ale in the "Make Your Best" series by Josh Weikert.

The third and fourth batches will be very similar to each other as well, the Pale and Dark Milds also of the "Make Your Best" series.

The main goals for these first four batches are to become familiar with my equipment and process, collect brewhouse data, and dial in brewing software.