This^ Ive followed this thread with dumbfounded interest.

I use a 17" boil pot and a quite vigorous, probably 5th gear boil from the previously supplied video yet I'm less then you state for boil off by quite a bit at about 1.85 to 2 gallons per hour.

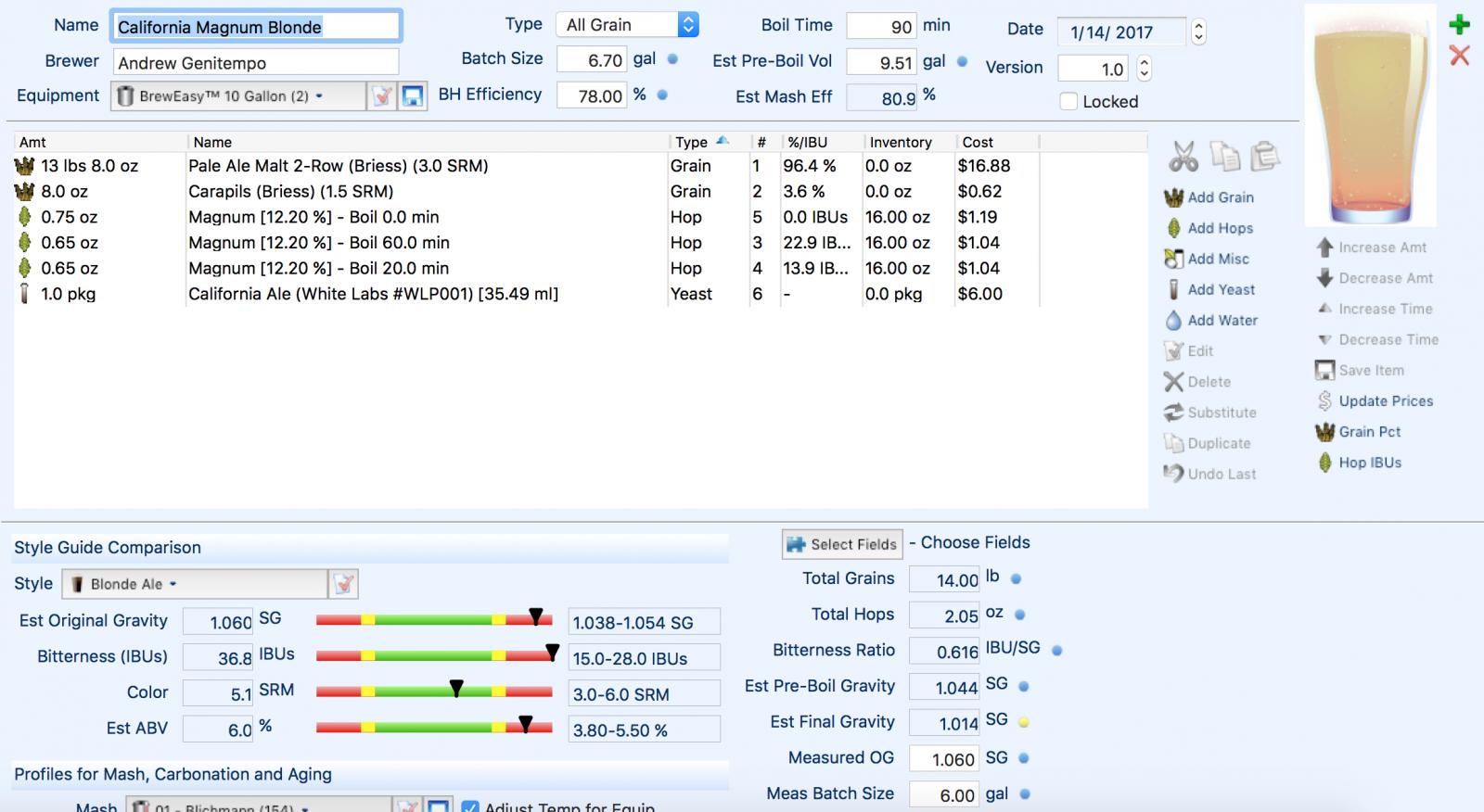

I have plenty of issues with beer smith as stated earlier but I have learned to put up with its idiosyncrasy's. Your mash efficiency is truly mind boggling though and something is just not right there.

It has to be the crush IMHO.

I will get flamed for this as a heretic, but I have to set my BHE in BS to 90% for my numbers to come out right, and my volume inputs and outputs are pretty spot on. I'm working with Priceless-brewing via PM and using his BIAB calculator as well and its pretty much confirming those numbers. I personally double crush at my LHBS even though they tell me I don't need too nor probably like me too..Priceless thinks my water may be naturally perfect for mash efficiency as a possibility but 60% is horrid indeed no mater what water your using.

I will continue to follow this and I wish you nothing but the best with your system. I'm sure your very frustrated.

Click on image to compare your boil to mine.

[/URL][/IMG]