So far I've done two brews on an eBIAB system I put together. It consists of a Spike Kettle, 5500W Element, Wilser Bag, False Bottom to keep the bag off the element, MKII Pump to recirculate during mash, Steam Slayer, and an Electric Brewing Supply control panel. I'm using Brewfather to setup recipes and use for the timers. I've got my equipment setup and measured the amount of loss through the hoses, pump, and chiller when transferring to the fermenter. I have my boil-off rate set to 0.5 gal/hr according to what other people using the Steam Slayer have experienced, and it seems pretty good after these two batches. I had Ward Labs do a water test on the water I am brewing with and am using the Water Adjustment wizard in Brewfather for epsom salt, gypsum, and calcium chloride additions in the mash. What I am curious about is when my overall efficiencies have been pretty low. My equipment profile in Brewfather is setup for 72%, just based on what I've seen others get with full volume BIAB. Below I'll post some screenshots of the batch results in Brewfather. I'd love to see if anyone has an suggestions on what I can do to increase the efficiency. Also as a note: The below beers were brewed from the very cheap MoreBeer all grain (unmilled base malts) from Amazon. Is it possible the grains are old and reducing the efficiency?

Grain Crush: Cereal Killer Mill set to 0.025"

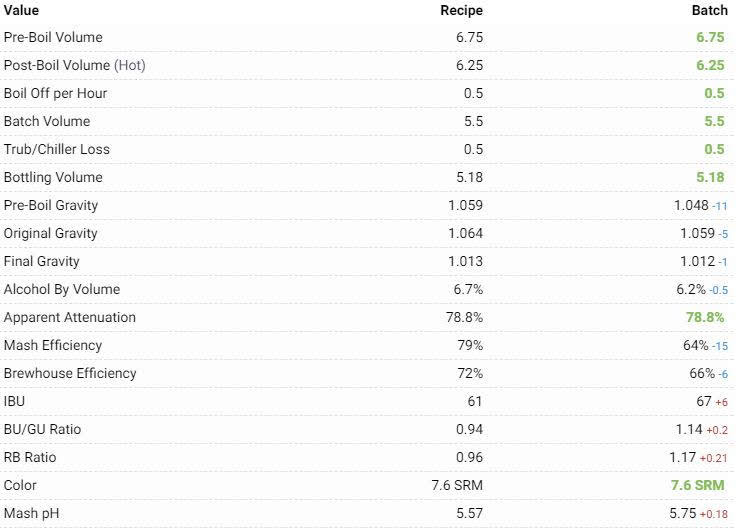

First Batch: Columbus IPA from MoreBeer

Notes: Mash pH measured to be 5.75 @ 153F (I realize now I don't think my pH meter is calibrated to handle temperatures this high), did not stir the mash at all other than when initially mashing in. No bag squeeze.

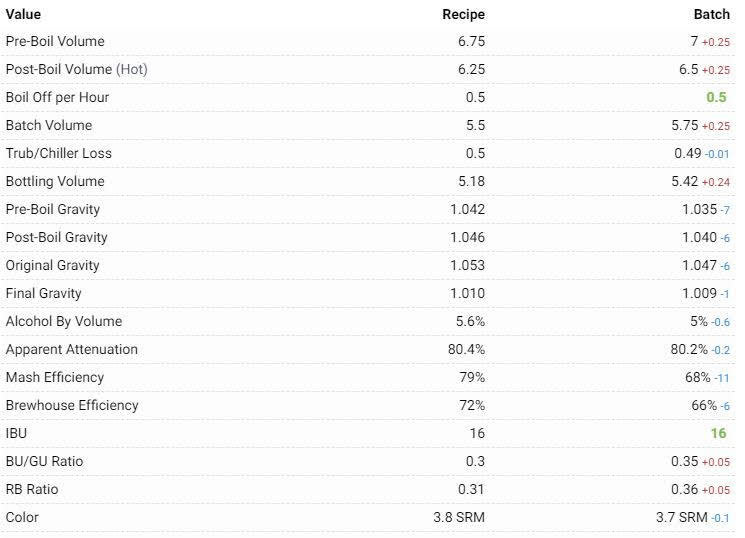

Second Batch: Blonde Ale from MoreBeer

Notes: Mash pH measured to be 5.62 @ 88.7F, added 4mL of 88% lactic acid to get to this. Stirred the mash every 15 minutes. No bag squeeze.

Grain Crush: Cereal Killer Mill set to 0.025"

First Batch: Columbus IPA from MoreBeer

Notes: Mash pH measured to be 5.75 @ 153F (I realize now I don't think my pH meter is calibrated to handle temperatures this high), did not stir the mash at all other than when initially mashing in. No bag squeeze.

Second Batch: Blonde Ale from MoreBeer

Notes: Mash pH measured to be 5.62 @ 88.7F, added 4mL of 88% lactic acid to get to this. Stirred the mash every 15 minutes. No bag squeeze.

Last edited: