Devon Brooks

Member

- Joined

- May 8, 2019

- Messages

- 18

- Reaction score

- 5

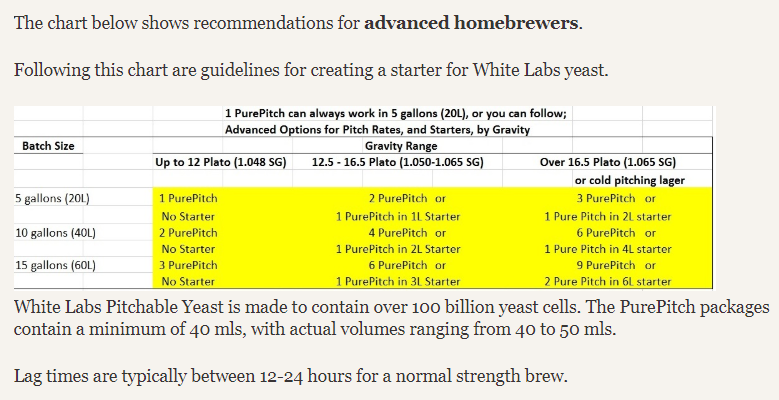

Hey guys. So made my first Lager a few weeks ago. it was an Oktoberfest/marzen. OG was around 1.49. After 4 days no yeast activity at 54 degrees. So I stirred with sanitized spoon to oxygenate and upped temp to 58. It began bubbling away and after 10 days stalled at 1.025. I was expecting it to finish around 1.013-14ish. I now know that I should've let the yeast start at a higher temp and then lower it to the 54 after that. I didn't make a starter, just a White Labs pure pitch. usually 1.050 and above I make a starter.

Do I repitch at higher temps with a US-05 or the like to have it finish out, or what do you think? What else should I have done for next time? TIA

Do I repitch at higher temps with a US-05 or the like to have it finish out, or what do you think? What else should I have done for next time? TIA