Mumathomebrew

Well-Known Member

Real newb at this. So be kind if I'm doing anything truly daft.

Final choice for an all grain attempt is a really simple recipe, cream of three crops, to begin with so it doesn't use up tons of grain whilst I learn.

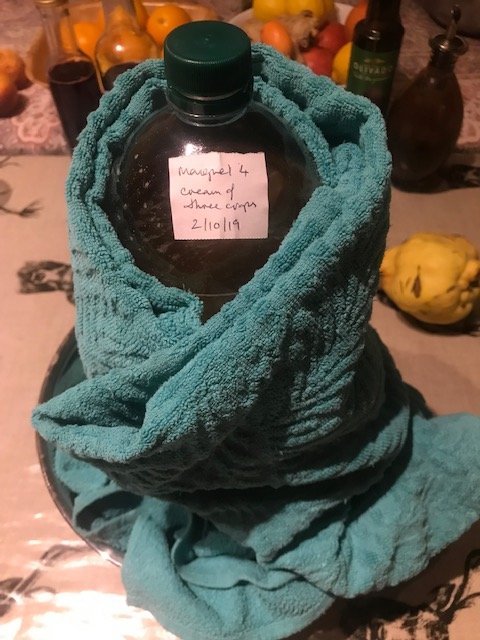

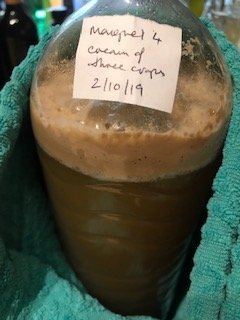

The only bit of apparatus I own that can keep water under consistent temperature control is an ultrasonic cleaner. So I tested the bath with just water to make sure it worked. It only holds a litre so these are going to be tiny, tiny experiments. I can always do a mini mash more than once if it works well enough.

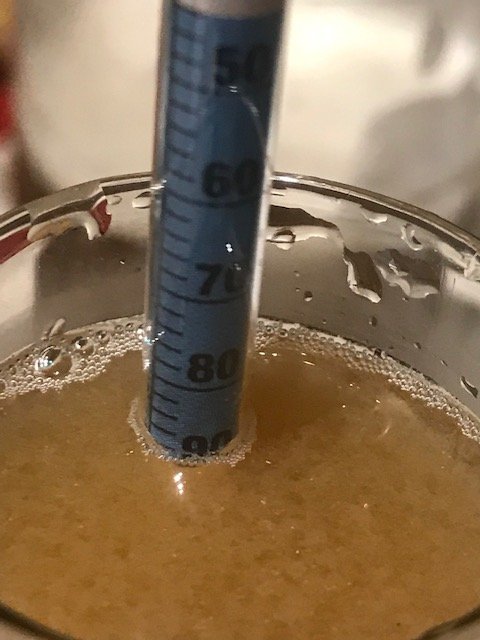

I've sewn a mini sparge bag for the basket and have scaled down the recipe to 1 litre. It's in and soaking, the temp on the display says 63*c which will actually be 66*c if the prior water test measurement was anything to go by. I'm now waiting to see what happens in 90 minutes time.

(I'd read about ultrasound helping alpha amylase production so I couldn't help but turn the US on for a second using half the grain. I left the other half of the grain unsplatted in case I'd killed amylases instead of helping them).

It's small and cute... but we'll see if it works or not. I just want to experiment with lots of different beer making recipes rather than make a ton of beer. It might just be far too small.

Cream of three crops

Scaled down figure for 1 L, ± quarter of a gallon (Original recipe for 10 gallons)

4.8 oz Maris otter pale (12lb Pale malt 2 row US)

1.6 oz flaked Maize (4lb corn, flaked)

0.4 oz flaked rice (1lb minute rice)

Original recipe says

OG 1.040 to FG 1.005

Simple infusion mash for 90 mins @152*f (66.66*c)

Boil 90 mins

Hops

1oz Williamette @60

1oz Crystal @60

It'll be interesting to see how much gets lost on a tiny boil. Maybe all.

Noting that the temp is struggling to be even, as the water outside the grist bag is turning the thermostat off too fast. It's mashing at nearer 55 so needs more attention to keep the temp up. Interesting.

Final choice for an all grain attempt is a really simple recipe, cream of three crops, to begin with so it doesn't use up tons of grain whilst I learn.

The only bit of apparatus I own that can keep water under consistent temperature control is an ultrasonic cleaner. So I tested the bath with just water to make sure it worked. It only holds a litre so these are going to be tiny, tiny experiments. I can always do a mini mash more than once if it works well enough.

I've sewn a mini sparge bag for the basket and have scaled down the recipe to 1 litre. It's in and soaking, the temp on the display says 63*c which will actually be 66*c if the prior water test measurement was anything to go by. I'm now waiting to see what happens in 90 minutes time.

(I'd read about ultrasound helping alpha amylase production so I couldn't help but turn the US on for a second using half the grain. I left the other half of the grain unsplatted in case I'd killed amylases instead of helping them).

It's small and cute... but we'll see if it works or not. I just want to experiment with lots of different beer making recipes rather than make a ton of beer. It might just be far too small.

Cream of three crops

Scaled down figure for 1 L, ± quarter of a gallon (Original recipe for 10 gallons)

4.8 oz Maris otter pale (12lb Pale malt 2 row US)

1.6 oz flaked Maize (4lb corn, flaked)

0.4 oz flaked rice (1lb minute rice)

Original recipe says

OG 1.040 to FG 1.005

Simple infusion mash for 90 mins @152*f (66.66*c)

Boil 90 mins

Hops

1oz Williamette @60

1oz Crystal @60

It'll be interesting to see how much gets lost on a tiny boil. Maybe all.

Noting that the temp is struggling to be even, as the water outside the grist bag is turning the thermostat off too fast. It's mashing at nearer 55 so needs more attention to keep the temp up. Interesting.