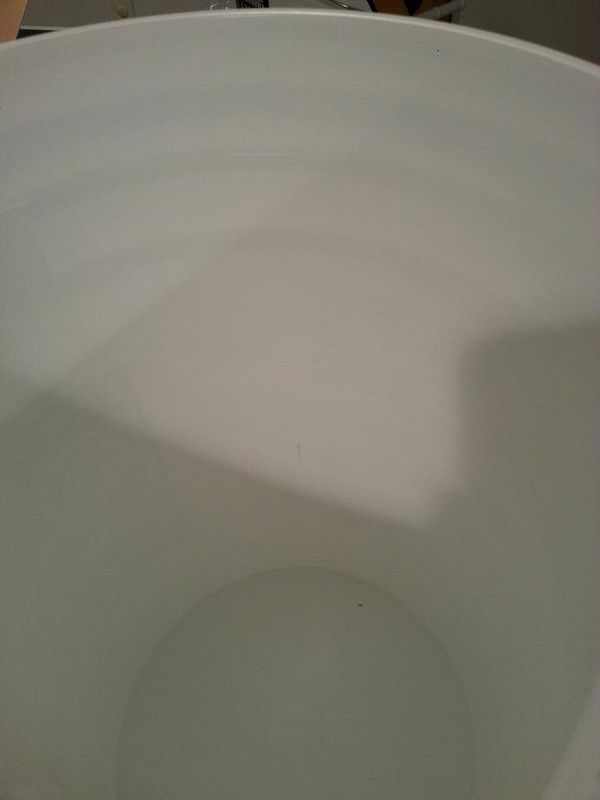

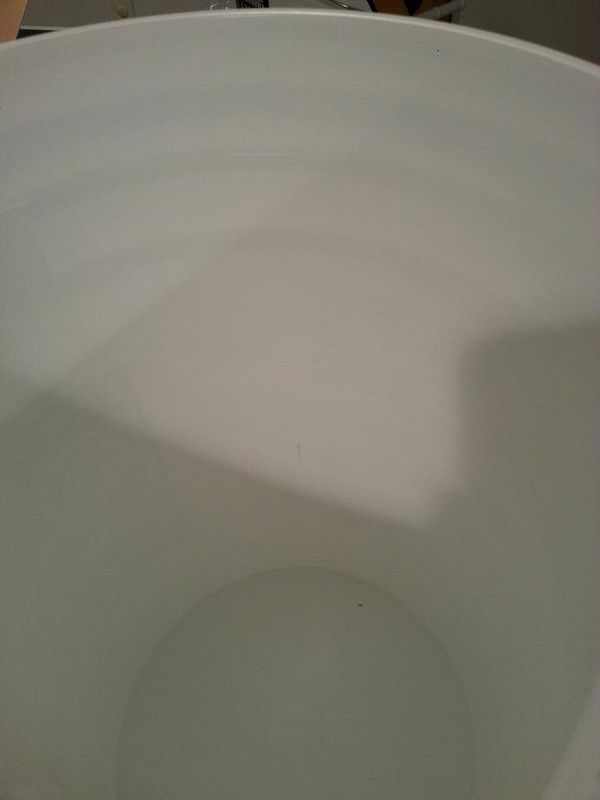

As the title suggests, I am a new homebrewer with only 1 batch (Brewer's Best Summer Ale extract ingredient kit) under my belt. In general I'd say it was quite successful, but I definitely had some inconsistency between bottles. Some of them had an almost popcorn-like harshness to them that I assume is from some kind of infection. As you can see in this photo, there is a small dark mark on the inside of my bottling bucket (vertical line in the middle of the photo, just above the shadow line). I cannot feel any difference when I run my fingers over that spot (no sharpness indicative of a scratch or anything), and I believe that the spot has been there since before I used the bucket for anything.

I have two basic questions:

1. Is that spot something that I should be concerned about (i.e. should I pick up a new bottling bucket before my next batch)?

2. If that spot is something that could introduce contamination to my beer, is it possible/likely to have some bottles taste great while others have the off flavor? Or is it more likely that I just didn't do a good enough job of cleaning/sanitizing some of the bottles?

Thanks all, looking forward to brewing up a Belgian Tripel for my next batch.

I have two basic questions:

1. Is that spot something that I should be concerned about (i.e. should I pick up a new bottling bucket before my next batch)?

2. If that spot is something that could introduce contamination to my beer, is it possible/likely to have some bottles taste great while others have the off flavor? Or is it more likely that I just didn't do a good enough job of cleaning/sanitizing some of the bottles?

Thanks all, looking forward to brewing up a Belgian Tripel for my next batch.